ABOUT STANDOFF INSULATORS

By eliminating direct physical contact between electrical components, insulated standoffs help prevent conditions that could lead to short circuits. Their role in ensuring the safety and efficiency of electrical systems is invaluable. Trust in our high-quality standoff insulators to provide the reliability and performance your applications demand, safeguarding your equipment and optimizing functionality.

What Materials are Used in Medium Voltage Standoff Insulators?

For example:

-

-

- Porcelain Insulators: Known for their durability and resistance to weathering.

- Epoxy Insulators: Lightweight and offer excellent electrical insulation properties.

- Cycloaliphatic Epoxy Insulators: Provide superior performance in harsh environments.

-

Applications and Benefits

-

-

- Porcelain Insulators: Commonly seen on electric poles and transformers, they are used to prevent electrical flashovers and maintain the integrity of electrical systems.

- Insulated Standoff: Essential for isolating bus bars from the ground, preventing high-powered electrons from jumping between conductors and causing sparks.

- Electrical Standoff Insulator: Used in various medium voltage applications to provide effective insulation and support.

- 15 kV Porcelain Insulators: Designed specifically for medium voltage switchgear, these insulators are robust and reliable.

-

Types of Medium Voltage Insulators Offered

-

-

-

-

- Busbar Standoff Insulator.

- Spool Insulator.

- Transformer Bushings.

- Feed Through Bushing.

- Post Insulators.

-

-

-

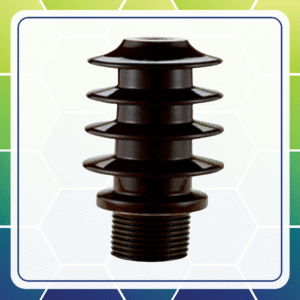

Busbar Standoff Insulators

By providing reliable insulation, these standoffs help maintain system integrity and safety. Whether for industrial applications or utility infrastructure, our busbar insulators offer the performance and reliability needed to support your electrical systems. Here are some specific uses for busbar insulators:

Electrical Switchgear:

-

-

- Switchboards and Control Panels: Busbar insulators and ceramic standoff insulators support and insulate busbars in switchboards and control panels, preventing short circuits and ensuring safe operation. 15 kV porcelain insulators are also used.

- Circuit Breakers and Disconnect Switches: They are also used in conjunction with circuit breakers, fuses and disconnect switches to provide secure and insulated connections.

-

Power Distribution Systems:

-

-

- Substations: In substations, busbar Standoff Insulators, and ceramic standoff insulators are used to support busbars that distribute power from incoming feeders to outgoing feeders, ensuring safe and reliable power distribution. 15 kV porcelain insulators are also used.

- Distribution Boards: They provide insulation and support for busbars in distribution boards, which distribute electrical power to various circuits within a facility.

-

Industrial Applications:

-

-

- Manufacturing Plants: Busbar Standoff Insulators are used in manufacturing plants to support and insulate busbars in heavy machinery and industrial equipment, ensuring efficient and safe power distribution.

- Electrical Furnaces: They are essential in electrical furnaces, providing insulation and support for busbars that handle high current loads.

-

Renewable Energy Systems:

-

-

- Solar Power Installations: Busbar Standoff Insulators are used in solar power installations to support and insulate busbars connecting solar panels to inverters, PV fuses, and other electrical equipment.

- Wind Turbines: In wind turbines, provide insulation and support for busbars that distribute power generated by the turbines to the grid.

-

Electric Vehicles and Charging Stations:

-

-

- EV Charging Infrastructure: Busbar insulators ceramic standoff insulators are used in electric vehicle (EV) charging stations to support and insulate busbars that handle high power levels required for fast charging.

- EV Power Distribution: They are also used in electric vehicles to insulate and support busbars in the power distribution system of the vehicle.

-

Marine and Offshore Applications:

-

-

- Ships and Offshore Platforms: Busbar Standoff Insulators are used in the electrical systems of ships and offshore platforms to provide insulation and support for busbars, ensuring safe and reliable power distribution in harsh marine environments. 15 kV porcelain insulators are also used.

- Marine Switchgear: Porcelain 15 kV switchgear insulators are also used in marine switchgear to insulate and support busbars that manage power distribution onboard vessels.

-

High-Voltage Applications:

-

-

- High-Voltage Switchgear: Busbar Standoff Insulators and ceramic standoff insulators are used in high-voltage switchgear to support and insulate busbars that handle high voltage levels, preventing arcing and ensuring safe operation.

- Transformers: They provide insulation and support for busbars in transformers, facilitating the efficient distribution of high-voltage power.

-

Commercial and Residential Buildings:

-

-

-

- Main Distribution Panels: Busbar Standoff Insulators are used in the main distribution panels of commercial and residential buildings to support and insulate busbars, ensuring safe and reliable power distribution to various circuits.

- Backup Power Systems: They are also used in backup power systems, such as generators and UPS systems, to provide insulation and support for busbars.

-

-

Standoff Insulators Materials and Design Considerations

- Porcelain 15 kV Switchgear Insulators: Feature a design that allows current to flow in an axial direction while providing radial insulation.

- Ceramic Standoff Insulators: Often have a ribbed design to manage voltage distribution and reduce stress.

- Porcelain Busbar Insulators: Known for their high mechanical strength and durability, making them suitable for outdoor and high-stress applications.

- Epoxy Busbar Insulators: Offer excellent electrical insulating properties and are resistant to weathering, making them ideal for various outdoor and indoor applications.

- Composite Busbar Insulators: Lightweight and resistant to pollution and vandalism, suitable for modern electrical systems requiring robust and reliable insulation.

Spool Insulators

Their robust design helps prevent short circuits and other electrical faults, enhancing the safety and reliability of the power distribution system. Whether for residential or industrial applications, spool insulators play a crucial role in maintaining the integrity of electrical systems. Here are some specific uses for spool insulators.

Load Banks

- Electrical Isolation and Conductor Support: Spool insulators provide robust support for conductors in low-voltage load banks, ensuring they are securely held while preventing electrical contact with other components.

- Prevention of Short Circuits: By isolating conductors from grounded or live components, spool insulators prevent short circuits that can lead to equipment damage or safety hazards.

- Mechanical Stability and High Tensile Strength: Spool insulators are designed to withstand mechanical stress, providing stability and durability in load banks where conductors may experience tension or vibration.

- Secure Mounting: They facilitate the secure mounting of conductors, ensuring they remain in position even under varying load conditions.

- Enhanced Safety through Minimizing the Risk of Electrical Arcs: By maintaining appropriate spacing between conductive parts, spool insulators help minimize the risk of electrical arcs, which can cause fires or equipment failure.

- Insulation in Adverse Conditions: Spool insulators are typically made of porcelain or composite materials that offer excellent insulation properties, even in adverse environmental conditions such as moisture or dust.

- Cost-Effective Solution Offering Durability and Longevity: Spool insulators are known for their durability and long lifespan, making them a cost-effective solution for maintaining low-voltage load banks over time.

Low Voltage Distribution Lines:

- Insulating Conductors: Spool insulators are commonly used to insulate conductors in low-voltage distribution lines, preventing electrical faults and ensuring safe power delivery.

- Mechanical Support: They provide mechanical support to conductors, maintaining the integrity of the power distribution system.

Service Drop Connections:

- Building Connections: Spool insulators are used in service drop connections where overhead power lines connect to buildings, ensuring safe and reliable power entry points.

- Pole to Building Transitions: They help in transitioning power lines from poles to buildings, providing necessary insulation and mechanical support.

Overhead Line Supports:

- Pole Mounted Equipment: Spool insulators are used to support overhead lines attached to poles, ensuring that the conductors are safely insulated from the pole and other structures.

- Crossarm Mounting: They are also mounted on cross-arms to provide insulation and support to multiple conductors in an overhead distribution system.

Transformer Connections:

- Pole-Mounted Transformers: Spool insulators are used to insulate and support conductors connecting to pole-mounted transformers, ensuring safe power delivery and reducing the risk of electrical faults.

- Distribution Transformers: They provide insulation for connections between distribution transformers and the overhead power lines.

Switchgear and Control Equipment:

- Support for Low Voltage Switchgear: Spool insulators are used in low voltage switchgear and porcelain 15 kV switchgear insulators provide insulation and mechanical support for internal and external wiring.

- Control Panels: They are also used in control panels to insulate and support conductors, ensuring the safe operation of the equipment.

Railway Electrification:

- Signal and Communication Lines: Spool insulators are used in railway systems to insulate and support signal and communication lines, ensuring the reliable operation of railway signaling systems.

- Low Voltage Power Distribution: They are used in low voltage power distribution systems within railway electrification to provide safe and reliable power supply.

Renewable Energy Systems:

- Solar Panel Installations: Spool insulators are used in solar power installations to insulate and support conductors connecting solar panels to inverters and other equipment.

- Wind Turbine Systems: They are also used in wind turbine systems for insulating and supporting low voltage connections within the turbine and between the turbine and the power grid.

Temporary Power Installations:

- Construction Sites: Spool insulators are used in temporary power installations at construction sites to provide safe and reliable insulation for low-voltage power distribution.

- Event Power Supplies: They are used to insulate and support conductors in temporary power supplies for events, ensuring safe and reliable power delivery.

Spool Insulators Material and Design Considerations

- Porcelain Insulators: Known for their high mechanical strength and durability, making them suitable for outdoor and high-stress applications.

- Glass Spool Insulators: Offer excellent electrical insulating properties and are resistant to weathering, making them ideal for various outdoor applications.

- Polymer Spool Insulators: Lightweight and resistant to pollution and vandalism, suitable for modern electrical systems requiring robust and reliable insulation.

Feed Through Bushings

-

-

- Provide safe passage for electrical conductors

- Ensure robust insulation and mechanical support

- Maintain system integrity and safety

- Reduce the risk of electrical faults and hazards

-

Here are some specific applications and uses for feed through bushings:

Transformers:

- Insulation and Connection: Feed-through bushings are used to connect the internal windings of transformers to external circuits while providing necessary insulation.

- High Voltage Applications: They are crucial in managing high voltage connections, preventing electrical arcs, and maintaining system integrity.

Switchgear:

- Medium Voltage Switchgear: Feed-through bushings provide insulated pathways for conductors in medium voltage switchgear, ensuring reliable operation and safety.

- Panel Penetration: They facilitate the safe passage of electrical conductors through switchgear panels, and porcelain 15 kV switchgear insulators maintaining the necessary insulation and separation from grounded metal parts.

Circuit Breakers:

- Internal Connections: Feed-through bushings are used to route conductors through the casing of circuit breakers, ensuring safe and reliable internal connections.

- High Voltage Circuit Breakers: In high voltage applications, they provide critical insulation and support for the conductors passing through the breaker housing.

Power Distribution Systems:

- Substations: Feed-through bushings are used in substations to connect various components such as transformers, circuit breakers, and busbars, ensuring safe and efficient power distribution.

- Outdoor Applications: Designed to withstand harsh environmental conditions, they are used in outdoor installations to provide reliable insulation for high-voltage conductors.

Industrial Equipment:

- Motor Control Centers: In industrial settings, feed through bushings are used in motor control centers to manage the connections between different sections while maintaining insulation.

- Heavy Machinery: They are employed to route electrical conductors through grounded barriers in heavy machinery, ensuring safe and reliable operation.

Power Generation Facilities:

- Generators: Feed through bushings provide a critical connection between the internal components of generators and external power systems, ensuring reliable operation and insulation.

- Turbine Systems: They are used in turbine systems to route conductors through grounded enclosures, maintaining necessary insulation and safety.

Renewable Energy Systems:

- Wind Turbines: Feed through bushings are used to connect the internal wiring of wind turbines to external circuits, providing reliable insulation and mechanical support.

- Solar Power Systems: In solar power installations, they ensure the safe passage of electrical conductors through grounded enclosures, maintaining system integrity.

Standard MV Feed Through Bushings

Feed Through Bushings Material and Design Considerations

Feed through bushings are made from materials such as porcelain, epoxy, or cycloaliphatic epoxy to handle various voltage levels and environmental conditions. Their design includes features to manage electric fields and prevent flashovers, ensuring the safety and reliability of electrical systems.-

-

- Porcelain Bushings: Known for their durability and resistance to weathering, suitable for outdoor and high voltage applications.

- Epoxy Bushings: Lightweight with excellent electrical insulation properties, ideal for medium voltage and indoor applications.

- Cycloaliphatic Epoxy Bushings: Offer superior performance in harsh environments, providing reliable insulation and mechanical support.

-

Transformer Bushings

- Connecting transformer windings to supply lines: Ensuring a secure and efficient link.

- Insulating feed-through conductors from the main transformer tank: Preventing electrical faults.

- Providing reliable electrical insulation: Enhancing system safety.

- Offering mechanical support for conductors: Maintaining structural integrity.

- Enhancing the safety and stability of power distribution systems: Contributing to overall system reliability.

Power Transformers:

- High Voltage Connections: Transformer bushings facilitate high voltage connections between internal transformer windings and external circuits, ensuring safe and reliable power transmission.

- Insulation: They provide essential insulation between high-voltage conductors and the grounded transformer tank, preventing electrical arcs and maintaining system integrity.

Distribution Transformers:

- Medium Voltage Applications: Bushings are used in distribution transformers to connect medium voltage windings to external power lines, ensuring efficient power distribution to residential and commercial areas.

- Protective Insulation: They ensure that the conductors are insulated from the transformer casing, reducing the risk of electrical faults and improving safety.

Power Generation:

- Generators: Transformer bushings are used in power generation plants to connect generators to transformers, enabling the safe transfer of generated electricity to the power grid.

- Auxiliary Transformers: In power plants, auxiliary transformers use bushings to manage connections between the plant's internal systems and the external power grid.

Substations:

- HV and EHV Applications: High voltage (HV) and extra high voltage (EHV) substations use transformer bushings to connect transformers to switchgear and other substation equipment, ensuring reliable power transmission.

- Phase-to-Ground Insulation: They provide phase-to-ground insulation, preventing electrical faults and ensuring the safe operation of the substation.

Industrial Applications:

- Industrial Transformers: Used in heavy industries, transformer bushings ensure safe and reliable connections between transformers and industrial machinery, supporting large-scale industrial operations.

- High Load Equipment: Bushings are essential for connecting transformers to high load equipment, ensuring efficient and safe power distribution within industrial facilities.

Renewable Energy Systems:

- Wind Farms: Transformer bushings connect wind turbine generators to transformers, facilitating the safe transmission of generated power to the grid.

- Solar Power Plants: In solar power installations, bushings are used in transformers to manage connections between solar inverters and the power grid, ensuring efficient power distribution.

Railway Electrification:

- Traction Transformers: Used in railway systems, bushings connect traction transformers to the overhead power lines, providing reliable power for electric trains.

- Signal Transformers: Bushings in signal transformers ensure the safe and reliable operation of railway signaling systems.

Underground and Subsea Transformers:

- Oil-Filled Transformers: Bushings are used in oil-filled transformers for underground and subsea applications, providing necessary insulation and ensuring reliable operation in challenging environments.

- Submersible Transformers: In subsea power distribution, bushings help connect submersible transformers to power cables, ensuring safe and efficient power transmission.

Transformer Bushings Material and Design Considerations

Transformer bushings are typically made from high-quality materials such as porcelain, epoxy resin, or composite materials, designed to withstand high voltages and harsh environmental conditions. Their design includes features to manage electric fields and prevent flashovers, ensuring the safety and reliability of electrical systems.- Porcelain Bushings: Known for their robustness and weather resistance, suitable for high voltage and outdoor applications.

- Epoxy Resin Bushings: Lightweight with excellent insulating properties, ideal for medium voltage and indoor applications.

- Composite Bushings: Offer superior performance in harsh environments, providing reliable insulation and mechanical support.

Post Insulators

Supporting Conductors in Substations:

- Switchgear Applications: Post insulators are used to support busbars and like porcelain 15 kV switchgear insulators these components help to maintain adequate clearance and prevent electrical arcing between conductive parts.

- Busbar Support: In substations, post insulators provide mechanical support for busbars, which are critical for distributing electrical power from transformers to various outgoing circuits.

Isolation in Power Distribution:

- Overhead Lines: Post insulators are used in overhead transmission lines to support and insulate conductors from grounded structures, such as poles and towers.

- Distribution Poles: They are mounted on distribution poles to hold conductors at a safe distance from each other and from the pole, preventing electrical faults.

High Voltage Applications:

- Circuit Breakers and Disconnectors: Post insulators are integral components in high voltage circuit breakers and disconnectors, providing the necessary insulation to handle high voltage currents safely.

- Transformer Terminals: They are used at transformer terminals to support and insulate the connections between the transformer windings and the external circuit.

Railway Electrification:

- Catenary Systems: Post insulators are used in railway electrification systems to support the overhead catenary wires, ensuring they remain properly aligned and insulated from support structures.

- Trackside Equipment: They insulate and support trackside electrical equipment, helping to maintain the integrity of the railway power supply.

Industrial Applications:

- Electrical Panels: In industrial electrical panels and switchboards, post insulators are used to support and insulate busbars and other conductive components.

- Power Plants: They are employed in power plants to support high voltage busbars and other components, ensuring safe and reliable operation of the plant's electrical systems.

Specialized Insulation Requirements:

- Harsh Environments: Post insulators made from materials like cycloaliphatic epoxy are used in harsh environmental conditions, such as areas with high pollution or coastal regions, due to their excellent resistance to moisture and contaminants.

- High Mechanical Strength Applications: In applications requiring high mechanical strength, such as wind turbines or seismic areas, post insulators provide the necessary support and stability.

Material Considerations for Post Insulators

Post insulators are made from various materials, each suited for specific applications:- Porcelain Post Insulators: Known for their high mechanical strength and excellent electrical insulating properties, porcelain insulators are widely used in high voltage applications.

- Epoxy Post Insulators: These insulators offer good resistance to environmental conditions and are lighter in weight compared to porcelain, making them suitable for a range of applications.

- Cycloaliphatic Epoxy Insulators: Ideal for outdoor and high pollution environments, these insulators provide excellent resistance to UV radiation, chemicals, and mechanical stress.

Post Insulators Design Features

Post insulators are designed to provide both electrical insulation and mechanical support. Key design features include:- Creepage Distance: The surface distance along the insulator to prevent electrical discharge, which is crucial in high voltage and polluted environments.

- Mechanical Strength: The insulator's ability to withstand mechanical loads, such as wind, weight of conductors, and other external forces.

- Weather Resistance: The ability to perform reliably in various weather conditions, including rain, snow, and extreme temperatures.

Electrical Insulators

Advanced Features

- Umbrella-like Disks: These modifications help prevent the accumulation of water droplets, reducing the conductive path of water during rain and further minimizing flashover risks.

- Ribbed Design: Insulators with multiple connected discs, known as the shed factor, distribute voltage more evenly to avoid unequal stress.