About Our Capacitors

Hill Tech is a leader in AC capacitors and DC film capacitors offering a full range of products. These are used in high voltage, low inductance applications, AC or DC filters, power factor correction, and Heavy duty three phase AC filter applications.

When choosing film capacitors, it is important to understand that not all AC capacitors or DC link capacitors are created equal. Our capacitors offer high electrical efficiency using special film technology. These metalized PET film capacitors and MKP capacitors reduce excess losses that create heat which leads to premature failure of film capacitors.

The cost of our AC capacitors or DC link capacitors may be initially higher than simpler-made capacitors using an older technology. We offer advantages in terms of increased life, lower power consumption, a potentially smaller design (not needing a heat sink), and greater ability to control the power into and out of your product.

Less power used means you can further reduce the overall cost of energy and the resulting thermal losses.

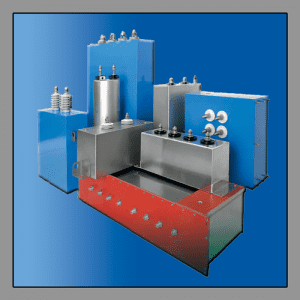

HEAVY DUTY THREE PHASE AC FILTER CAPACITORS

These are High-End Capacitors used for three-phase AC Filter applications, notable for their high AC-voltage load capacity. Many extreme or sophisticated operating conditions such as AC filtering and power factor correction in wind power, UPS, and harmonic filtering in three-phase mains with high or unusual levels of harmonic distortion, will benefit from the heavy-duty construction.

Our AC Capacitors have very low series resistance and a small self-inductance. The uncomplicated design principle is the inclination of short winding elements with a comparably large diameter, in combination with “wavecut” technology, providing high RMS and surge current strength.

Internally the three capacitor elements are connected in a delta and filled with environmentally friendly plant oil for enhanced heat dissipation and improved internal insulation. Many AC capacitors are also available as completely dry where a nitrogen filling is used on request. Screw terminals are finger-proof rated IP20 and make for simple and reliable connections and easy addition of IP20-resistors or reactors for discharge.

Other ranges are equipped with terminals optimized for use in filters with very high harmonic frequencies of >1 kHz (high frequency capacitors). Note the standard design has a long-term stable capacitance tolerance of ±5%. Tighter tolerances are available on request.

Very good self-healing characteristics and integrated overpressure protection ensure safe operation and controlled disconnection in the event of overload or failure at the end of operating life.

AC AND DC CAPACITORS WITH LARGE CAPACITANCES

We offer a standard range of specially designed large capacitances due to the special MKP and metalized PET film coating patterns used combined with ingenious winding geometries and advanced internal construction. We are able to provide large capacitance, with very small self-inductance and high surge current sustaining capability (up to 1200kA) as well as the possibility for high RMS currents (up to 1000A). These technologies are also applicable to snubber capacitors and high frequency capacitors.

Standard sizes cover a capacitance range for dc link capacitors from 40000μF/500V and 53000μF/900V DC up to 1450μF 5000V DC). Custom designs can accommodate considerably higher ratings of capacitance and voltage: voltages up to 17kV AC/12kVrms and 25kV DC. The exact capacitance ratings depend on the user's specific requirements.

Instead of flat pack windings, capacitance is formed by homogeneous cylindrical windings, avoiding the mechanical stress and instabilities at the edges of flat packs. The capacitors are housed in aluminum or steel cases and filled with solid resin, which makes them unquestionably dry and leakage-proof, and entirely impervious to mechanical shocks and vibration. Their size, shape, terminals, and mounting, can be adapted to your requirements.

Special terminals permit a considerable reduction in self-inductance which can be further diminished by construction adjustments if required. At the same time, our capacitors are extremely overvoltage-proof. This makes them well-suited for DC-link circuits of converters, tuned filter circuits, etc..

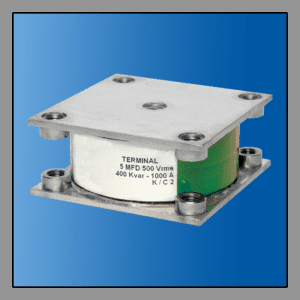

AC-DC FILM CAPACITORS FOR HIGH VOLTAGE, LOW INDUCTANCE

These provide long-term safe operation in power electronics, in particular in low inductance buffer circuits with higher voltages and in discharge circuits, where the need for low inductance poses problems. Traditional high voltage capacitors are filled with oil, and the generous bushings required for clearance/creepage as well as internal safety mechanisms add substantially to the self-inductance of the capacitor.

Based on our proprietary films our metalized PET film capacitors and MKP (metallized polypropylene film) capacitors provide a range of high-voltage capacitors in self-healing technology, using special metalizing patterns. These technologies are also applicable to snubber capacitors and high frequency capacitors.

Despite the high voltage ratings, these can be made in dry technology and without expensive bushings. For optimized self-inductance, they are made without a safety mechanism; by using a clever internal design they can be laid out and rated in such a way that partial dielectric discharges and consequential risk of failures in the customer's application are reduced to a minimum. The all-in-one; high RMS and surge currents combined with low self-inductance are done by using sophisticated metalizing patterns, special sinusoidal dual-slitting technology, and clever winding geometries.

The low series resistance version provides high pulse strength and is especially suited for the damping of GTO thyristors and low-inductance buffer circuits with high RMS currents. Their very low self-inductance makes them also suitable for use in high-current applications with medium frequencies and for high frequency capacitors. Along with their very good ratio of capacitance to volume, these capacitors have high pulse strength and very good self-healing characteristics without loss or shift of capacitance.

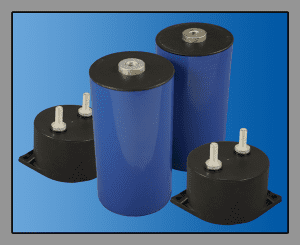

A series, which are very similar in design and electrical features, have been optimized particularly for large capacitances at high operating voltages. These are housed in flame-retardant plastic cans (V0) and filled with solid resin. Special care has been taken both in terms of design and conservative electrical rating, to ensure reliable operation even under tough environmental conditions. Connection is usually made through robust axial terminals with internal threads. If needed the same construction is available for radial connection through robust studs with M8 thread, providing two brackets at the base of the can which make for convenient mounting.

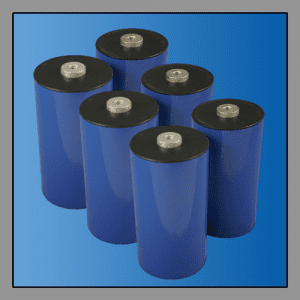

HIGH DENSITY DC FILM CAPACITORS

In its place, the user gets a superior technical solution within the same - or even less - space, providing:

- Superior voltage and current strength.

- A dramatic increase in operational life.

- Drastic reduction of failures.

- Minimization of power dissipation losses.

- Substantial reduction of self-inductance and series resistance.

- More exact manufacturing tolerances.

- Elimination of sharing resistors.

These capacitors similarly offer extra capacitance where strong current capability is to be combined with perfect smoothing. Also, its compact cylindrical aluminum (NT /NZ) or plastic (N4) can design is ideal for both the electrical and mechanical requirements of snubber capacitors and high frequency capacitors need by high-speed IGBT converters.