ABOUT WIRE & TAPE WOUND POWER RESISTORS

When you need to dissipate a few hundred watts to several thousand watts per element, wire or tape wound resistors are the preferred technology. The simple wire wound resistor construction consists of winding a high resistivity material around an insulating core.

Depending on the application we typically wind around a ceramic core with a wire made from a Nickel-Chromium alloy also known as Nichrome wire. Once wound, various terminations are added and the resistance wire is spot welded to these terminals providing electrical contact. Lastly, the assembly can be encapsulated to protect it from adverse conditions such as moisture and physical damage. We encapsulate the resistor by applying several coats of vitreous enamel and then firing to create a durable coating.

In the case of open-type wire wound resistors, these are close wound with an oxidized resistance wire. We supply these with a standard adjustable tapping clip.

Minimizing the temperature coefficient (TCR) is also an important consideration. TCR is the resistance change with temperature and is stated in ppm/°C. For example, a resistor rated at 100ppm/°C, the resistance will not change more than 100O for each 1MO of the resistors' value for a temperature change of 1°C.

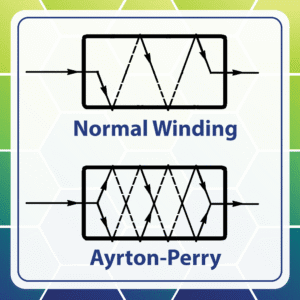

LOW CAPACITANCE AND INDUCTANCE WINDING METHOD - AYRTON-PERRY

We offer an Ayrton-Perry winding method for resistors in AC applications. This is especially important in high-frequency designs where low capacitance and inductance are needed. See the below diagram.

The Ayrton-Perry winding is like a simple resistor winding except that two opposing windings are applied to the core. The current in these windings is applied in opposite directions to minimize the inductance. We produce the windings close to each other similar to bifilar windings to reduce the resistors winding capacitance.

AYRTON-PERRY WINDING DIAGRAM

HIGHLY CUSTOMIZABLE AND MEDIUM VOLTAGE OPTIONS

We can provide unique resistance values unmounted and in various mounting options that most other manufacturers will not consider for low quantities.

For medium voltage applications, we manufacture resistors using dielectrics materials and manufacturing techniques suitable for these applications. Our medium voltage resistor designs take into account important parameters such as creepage and clearance distances which are a concern at these voltages.

VITREOUS ENAMELED WIRE WOUND - TYPE PE

Resistors are available in a range from 20 Watts to 500 Watts. Nickel-Chrome wire wound resistor winding is fully protected using several coats of vitreous enamel.

The coated resistor element is fired at a controlled high temperature to produce a highly reliable end product, capable of withstanding adverse conditions. To ensure reliable connections resistors come with terminal tags suitable for screws, and some sizes come with ‘Faston' terminals.

Terminal bands are spot welded in position on the heat resistant ceramic form, and the winding is then spot welded to the connecting terminal before the enameling process. The terminal bands are therefore an integral part of the resistor, protected by the vitreous coating.

Standard Ohmic Values 30 to 130 Watts

| Standard Ohmic Values & Tolerances |

|

Watts |

30 |

40 |

45 |

60 |

90 |

130 |

|

| Type |

|

Ohmic Value |

Tolerance |

| Fixed Wire Wound |

Min |

2R2 |

4R7 |

4R7 |

4R7 |

10R |

10R |

> 10R +/- 5% |

| Fixed Wire Wound |

Max |

5K0 |

10K |

10K |

15K |

30K |

60K |

≤ 10R +/- 10% |

| Fixed Tape Wound |

Min |

0R02 |

0R15 |

0R2 |

0R2 |

0R3 |

0R7 |

+/- 10% |

| Fixed Tape Wound |

Max |

2R0 |

4R5 |

4R5 |

4R5 |

9R0 |

9R0 |

+/- 10% |

| Non-Inductive |

Min |

1R0 |

2R0 |

2R0 |

3R0 |

3R0 |

5R0 |

+/- 10% |

| Non-Inductive |

Max |

500R |

500R |

500R |

500R |

1K0 |

1K5 |

+/- 10% |

| Adjustable |

Min |

2R2 |

2R2 |

4R7 |

4R7 |

8R2 |

15R |

+/- 10% |

| Adjustable |

Max |

1K3 |

3K9 |

2K2 |

3K9 |

6K2 |

11K |

+/- 10% |

Standard Ohmic Values 150 to 380 Watts

| Standard Ohmic Values & Tolerances |

|

Watts |

150 |

180 |

220 |

320 |

380 |

|

| Type |

|

Ohmic Value |

Tolerance |

| Fixed Wire Wound |

Min |

12R |

22R |

22R |

33R |

47R |

> 10R +/- 5% |

| Fixed Wire Wound |

Max |

70K |

100K |

120K |

120K |

125K |

≤ 10R +/- 10% |

| Fixed Tape Wound |

Min |

0R8 |

1R0 |

1R0 |

1R5 |

1R5 |

+/- 10% |

| Fixed Tape Wound |

Max |

10R |

20R |

20R |

30R |

30R |

+/- 10% |

| Non-Inductive |

Min |

6R0 |

7R0 |

10R |

25R |

30R |

+/- 10% |

| Non-Inductive |

Max |

1K5 |

1K5 |

1K5 |

2K0 |

2K5 |

+/- 10% |

| Adjustable |

Min |

16R |

20R |

27R |

36R |

43R |

+/- 10% |

| Adjustable |

Max |

13K |

16K |

22K |

22K |

22K |

+/- 10% |

Dimensional Charts - Vitreous Enameled Wire Wound Resistors

Time Ratings for Vitreous Enameled Resistors

| Time Ratings for Vitreous Enameled Resistors |

| Style |

Size (cm) |

Winding (cm) |

Continuous Rating 280°C |

10 Second Rating |

5 Second Rating |

1 Second Rating |

0.5 Second Rating |

Volts Max (Vm) |

| PE30 |

5.1 x 1.9 |

2.6 |

30 Watts |

200 Watts |

400 Watts |

600 Watts |

1300 Watts |

360 Watts |

| PE40 |

10.2 x 1.9 |

7.7 |

40 Watts |

300 Watts |

600 Watts |

900 Watts |

1800 Watts |

1080 Watts |

| PE45 |

5.1 x 3.2 |

2.6 |

45 Watts |

400 Watts |

800 Watts |

1300 Watts |

2600 Watts |

360 Watts |

| PE60S |

7.0 x 3.2 |

4.5 |

60 Watts |

600 Watts |

1200 Watts |

1900 Watts |

3800 Watts |

630 Watts |

| PE60L |

8.9 x 2.2 |

6.4 |

60 Watts |

600 Watts |

1200 Watts |

1900 Watts |

3800 Watts |

890 Watts |

| PE90S |

10.2 x 3.2 |

6.2 |

90 Watts |

800 Watts |

1600 Watts |

2600 Watts |

5200 Watts |

860 Watts |

| PE90L |

16.5 x 2.2 |

14 |

90 Watts |

800 Watts |

1600 Watts |

2600 Watts |

5200 Watts |

1900 Watts |

| PE130 |

15.2 x 3.2 |

11.2 |

130 Watts |

1000 Watts |

2000 Watts |

3300 Watts |

6600 Watts |

1500 Watts |

| PE150 |

17.8 x 3.2 |

13.8 |

150 Watts |

1200 Watts |

2400 Watts |

3900 Watts |

7900 Watts |

1900 Watts |

| PE180 |

21.6 x 3.2 |

17.6 |

180 Watts |

1500 Watts |

3000 Watts |

4950 Watts |

9900 Watts |

2400 Watts |

| PE220 |

26.7 x 3.2 |

22.7 |

220 Watts |

2200 Watts |

4400 Watts |

7260 Watts |

14500 Watts |

3100 Watts |

| PE320 |

26.7 x 4.5 |

22.7 |

320 Watts |

3500 Watts |

7000 Watts |

11550 Watts |

23100 Watts |

3100 Watts |

| PE380 |

30.5 x 4.5 |

26.5 |

380 Watts |

6000 Watts |

12000 Watts |

19800 Watts |

39600 Watts |

3700 Watts |

| PE600 |

30.5 x 5.4 |

26.5 |

600 Watts |

9400 Watts |

18800 Watts |

31000 Watts |

62000 Watts |

3700 Watts |

| PE750 |

35.6 x 5.4 |

31.6 |

750 Watts |

11800 Watts |

23600 Watts |

38900 Watts |

77800 Watts |

4400 Watts |

| PT750 |

35.6 x 5.4 |

31.6 |

1000 Watts |

15700 Watts |

31400 Watts |

52000 Watts |

104000 Watts |

4400 Watts |

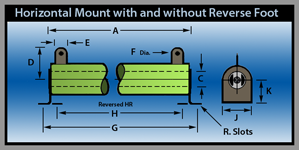

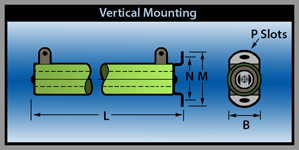

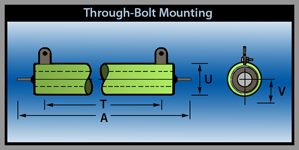

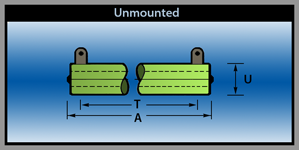

PE Type resistors mounting and connection configurations

- PE Type - Unmounted Vitreous Enameled Resistors with two standard connection tabs.

- PE Type Tapped - Unmounted Vitreous Enameled Resistors with multiple connection tabs.

- PE-Adj Type - An adjustable tapping clip included. Moving this clip along an exposed track on the side of the resistor provides a range of resistances.

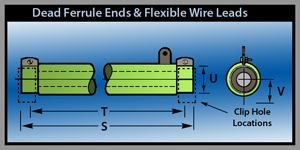

- PE Style -WF - Live Ferrule ends allow for a flexible wire leads to connect to ferrule ends, making this style of resistor suitable for mounting directly into special mounting clips.

- PE Style -F - Dead Ferrule ends allow for the resistor to be connected to standard terminal and attaching the ferrules to standard mounting clips.

- TB Mounting Style - This configuration is suitable for mounting resistors directly to a panel of 6mm or less in thickness. It consists of cupped washers in each end of the resistor with a tie-rod protruding from each end.

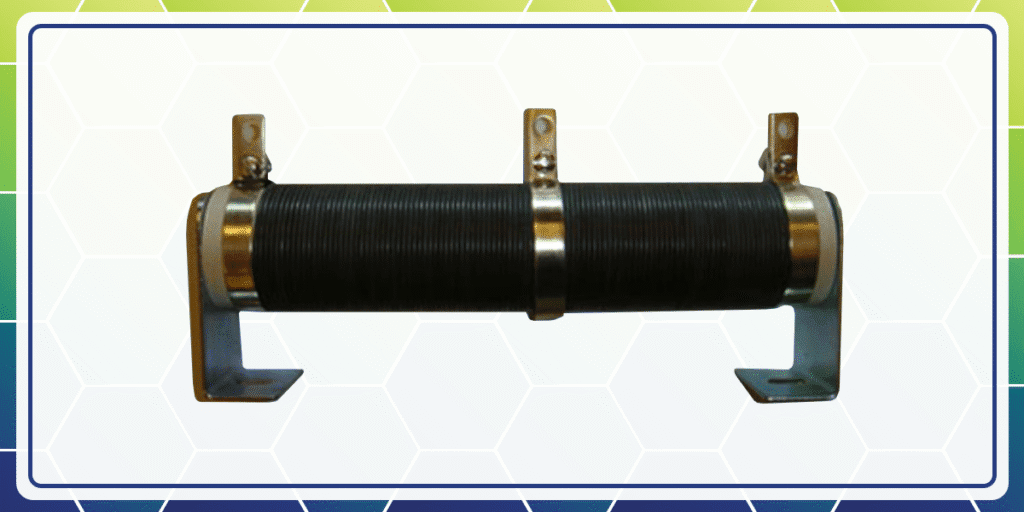

- H Mounting Style - L- brackets are used for horizontal mounting, and connection tabs provide the electrical contact. The mounting brackets are attached by tie-rods and fixing nuts to ensure that the resistor will not rotate about its axis.

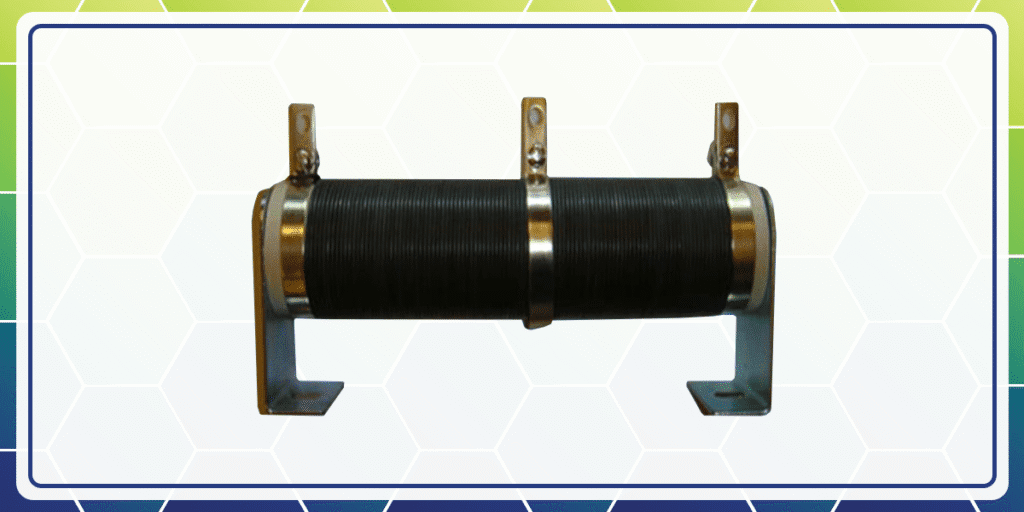

- HR Mounting Style - Similar to “H” above except the horizontal feet are reversed. This is ideal for applications where space is at a premium.

- V Mounting Style - This provides vertical mounting by means of a fixed bracket at one end which is appropriate for panel mounting.

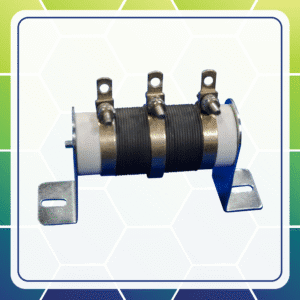

OPEN WIRE WOUND – PB TYPE

Resistors are available in a range from 30 Watts to 380 Watts. Open Wire Wound Resistors are close wound with oxidized Nickel-Chrome wire. Each resistor is fitted with an adjustable tapping clip as standard.

To ensure reliable connections resistors come with terminal tags suitable for screws, and some sizes come with ‘Faston' terminals. Terminal bands are spot welded in position on the heat resistant ceramic form, and the winding is then spot welded to the connecting terminal. The terminal bands are an integral part of the resistor.

Standard Ohmic Values 30 to 90 Watts

| Standard Ohmic Values & Power Ratings |

| Series |

|

PB30 |

PB40 |

PB45 |

PB60L |

PB60S |

PB90L |

PB90S |

| Watts |

|

30 |

40 |

45 |

60 |

60 |

90 |

90 |

| Ohmic Values One Tap |

Min. |

0R2 |

0R5 |

0R3 |

0R5 |

0R4 |

0R5 |

0R4 |

| Max. |

510R |

1K0 |

720R |

1K3 |

1K3 |

2K1 |

2K1 |

Standard Ohmic Values 130 to 380 Watts

| Standard Ohmic Values & Power Ratings |

| Series |

|

PB130 |

PB150 |

PB180 |

PB220 |

PB320 |

PB380 |

| Watts |

|

130 |

150 |

180 |

220 |

320 |

380 |

| Ohmic Values One Tap |

Min. |

0R4 |

0R5 |

0R7 |

0R7 |

1R0 |

1R2 |

| Max. |

3K2 |

4K0 |

5K2 |

6K8 |

9K8 |

11K5 |

Dimensional Charts - Open Wire Wound Resistors

The following mounting configurations are available for PB style resistors

- TB Mounting Style - This configuration is suitable for mounting resistors directly to a panel of 6mm or less in thickness. It consists of cupped washers at each end of the resistor with a tie-rod protruding from each end.

- H Mounting Style - L- brackets are used for horizontal mounting, and connection tabs provide the electrical contact. The mounting brackets are attached by tie-rods and fixing nuts to ensure that the resistor will not rotate about its axis.

- HR Mounting Style - Similar to “H” above except the horizontal feet are reversed. This is ideal for applications where space is at a premium.

- V Mounting Style - This provides vertical mounting utilizing a fixed bracket at one end which is appropriate for panel mounting.

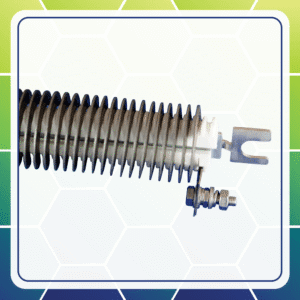

HEAVY DUTY VITREOUS ENAMELED TAPE WOUND RESISTORS – PT TYPE

Continuous Power Ratings are available from 250 Watts to 1000 Watts. For pulse ratings, refer to the "Continuous & Intermittent" and "Continuous & Short Term" Power Rating tables below.

The resistor winding is fully protected using several coats of vitreous enamel. The coated resistor element is fired at a controlled high temperature to produce a highly reliable resistor, capable of withstanding adverse conditions. Resistors are edge-wound with corrugated tape for low Ohmic Values.

Improved heat dissipation because of the increased surface area using corrugated tape wound resistors provides a power rating, up to approximately 25% greater than that of the equivalent wire wound resistor. We provide our tape-wound resistors with an adjustable tapping clip.

When needed to prevent circuit overloads we provide resistors fitted with thermal cut-outs. These operate a contact disconnecting the resistor from the circuit. The minimum and maximum resistance values given below are available within a range of standard resistance alloy. Upon request, we supply resistors in a Heavy-Duty Enclosure.

Power Ratings: Continuous & Intermittent

|

Power Ratings: Continuous & Intermittent |

| Part Number |

Continuous |

Intermittent (Seconds) |

Ohmic Values |

|

|

30 |

60 |

120 |

180 |

240 |

300 |

Min. |

Max. |

| PT200H |

250 |

1375 |

825 |

625 |

500 |

375 |

310 |

0.6 |

25 |

| PT300H |

400 |

2200 |

1320 |

1000 |

800 |

600 |

500 |

0.6 |

30 |

| PT400H |

525 |

2900 |

1730 |

1310 |

1050 |

785 |

655 |

1 |

30 |

| PT450H |

600 |

3300 |

1980 |

1500 |

1200 |

900 |

750 |

1.5 |

40 |

| PT600H |

800 |

4400 |

2640 |

2000 |

1800 |

1200 |

1000 |

3 |

60 |

| PT750H |

1000 |

5500 |

3300 |

2500 |

2000 |

1500 |

1250 |

3.5 |

100 |

|

|

Operating Time in any 15 Minute Period |

|

Power Ratings: Continuous & Short Term

|

Power Ratings: Continuous & Short Term |

| Part Number |

Continuous |

Short Term (Seconds) |

Ohmic Values |

|

|

5 |

10 |

20 |

Min. |

Max. |

| PT200H |

250 |

5000 |

3750 |

2250 |

0.6 |

25 |

| PT300H |

400 |

8000 |

6000 |

3600 |

0.6 |

30 |

| PT400H |

525 |

10500 |

7875 |

4700 |

1 |

30 |

| PT450H |

600 |

12000 |

9000 |

5400 |

1.5 |

40 |

| PT600H |

800 |

16000 |

12000 |

7200 |

3 |

60 |

| PT750H |

1000 |

20000 |

15000 |

9000 |

3.5 |

100 |

|

|

Operating 1x Per Hour |

|

Enameled Heavy Duty Tape Wound Resistors

| Enameled Heavy Duty Tape Wound Resistors |

| Part Number |

Dimensions (mm) |

| Watts |

A |

B |

C |

D |

E |

F |

G |

H |

J |

K |

L |

| PT200H |

250 |

152 |

44 |

29 |

43 |

9.5 |

5 |

190 |

173 |

44 |

51 |

7 x 14 |

| PT300H |

400 |

203 |

44 |

29 |

43 |

9.5 |

5 |

241 |

223 |

44 |

51 |

7 x 14 |

| PT400H |

525 |

254 |

44 |

29 |

43 |

9.5 |

5 |

292 |

274 |

44 |

51 |

7 x 14 |

| PT450H |

600 |

305 |

44 |

29 |

43 |

9.5 |

5 |

343 |

325 |

44 |

51 |

7 x 14 |

| PT600H |

800 |

305 |

54 |

38 |

50 |

9.5 |

5 |

356 |

333 |

54 |

76 |

7 x 17 |

| PT750H |

1000 |

356 |

54 |

38 |

50 |

9.5 |

5 |

406 |

384 |

54 |

76 |

7 x 17 |

PT Type resistors mounting and connection configurations

- H Mounting Style - L- brackets are used for horizontal mounting, and connection tabs provide the electrical contact. The mounting brackets are attached by tie-rods and fixing nuts to ensure that the resistor will not rotate about its axis.

- HR Mounting Style - Similar to “H” above except the horizontal feet are reversed. This is ideal for applications where space is at a premium.

HEAVY DUTY OPEN TAPE WOUND RESISTORS – PHD TYPE

Continuous Power Ratings are available from 200 Watts to 7500 Watts. For pulse ratings, refer to the "Continuous & Intermittent" and "Continuous & Short Term" Power Rating tables below. On these edgewound power resistors, the power rating can be greater than that of the equivalent wire-wound resistor, due to the increased heat dissipation provided by the tape. We provide an option with Tape-wound resistors for an adjustable tapping clip.

We can quickly supply direct replacements for difficult values to obtain in the PFE series edgewound or EDGF edgewound power resistors. Thermal Cut-outs are mounted to some resistors to operate a contact to disconnect the resistor from the circuit preventing overload damage. The minimum and maximum resistance values are below in a variety of standard resistance alloys. Upon request, we supply resistors in a Heavy-Duty Enclosure.

Power Ratings: Continuous & Intermittent

|

Power Ratings: Continuous & Intermittent |

| Part Number |

Continuous |

Intermittent (Seconds) |

Ohmic Values |

|

|

30 |

60 |

120 |

180 |

240 |

300 |

Min. |

Max. |

| PHD200 |

200 Watts |

1100 Watts |

660 Watts |

500 Watts |

400 Watts |

300 Watts |

250 Watts |

0.45 |

872 |

| PHD300 |

300 Watts |

1650 Watts |

990 Watts |

750 Watts |

600 Watts |

450 Watts |

375 Watts |

0.67 |

1294 |

| PHD400 |

400 Watts |

2200 Watts |

1320 Watts |

1000 Watts |

800 Watts |

600 Watts |

500 Watts |

0.9 |

1700 |

| PHD450 |

450 Watts |

2500 Watts |

1500 Watts |

1130 Watts |

900 Watts |

690 Watts |

570 Watts |

1.06 |

2100 |

| PHD600 |

600 Watts |

3200 Watts |

1930 Watts |

1460 Watts |

1170 Watts |

880 Watts |

740 Watts |

1.35 |

2600 |

| PHD750 |

750 Watts |

4000 Watts |

2420 Watts |

1830 Watts |

1460 Watts |

1100 Watts |

920 Watts |

1.6 |

3100 |

|

|

Operating Time in any 15 Minute Period |

With Tap |

Power Ratings: Continuous & Short Term

|

Power Ratings: Continuous & Short Term |

| Part Number |

Continuous |

Short Term (Seconds) |

Ohmic Values |

|

|

5 |

10 |

20 |

Min. |

Max. |

| PHD200 |

200 Watts |

4000 Watts |

3000 Watts |

1800 Watts |

0.45 |

872 |

| PHD300 |

300 Watts |

6000 Watts |

4500 Watts |

2700 Watts |

0.67 |

1294 |

| PHD400 |

400 Watts |

8000 Watts |

6000 Watts |

3600 Watts |

0.9 |

1700 |

| PHD450 |

450 Watts |

9000 Watts |

6700 Watts |

4000 Watts |

1.06 |

2100 |

| PHD600 |

600 Watts |

12300 Watts |

9200 Watts |

5500 Watts |

1.35 |

2600 |

| PHD750 |

750 Watts |

14700 Watts |

11000 Watts |

6600 Watts |

1.6 |

3100 |

|

|

Operating 1x Per Hour |

With Tap |

Open Wound Heavy Duty Resistors

| Open Wound Heavy Duty Resistors |

| Part Number |

Dimensions (mm) |

| Watts |

A |

B |

C |

D |

E |

F |

G |

H |

J |

K |

L |

| PHD200 |

200 |

152 |

44 |

29 |

43 |

9.5 |

5 |

190 |

173 |

44 |

51 |

7 x 14 |

| PHD300 |

300 |

203 |

44 |

29 |

43 |

9.5 |

5 |

241 |

223 |

44 |

51 |

7 x 14 |

| PHD400 |

400 |

254 |

44 |

29 |

43 |

9.5 |

5 |

292 |

274 |

44 |

51 |

7 x 14 |

| PHD450 |

450 |

305 |

44 |

29 |

43 |

9.5 |

5 |

343 |

325 |

44 |

51 |

7 x 14 |

| PHD600 |

600 |

305 |

54 |

38 |

50 |

9.5 |

5 |

356 |

333 |

54 |

76 |

7 x 17 |

| PHD750 |

750 |

356 |

54 |

38 |

50 |

9.5 |

5 |

406 |

384 |

54 |

76 |

7 x 17 |

The following mounting configurations are available for PHD style resistors

- H Mounting Style - L- brackets are used for horizontal mounting, and connection tabs provide the electrical contact. The mounting brackets are attached by tie-rods and fixing nuts to ensure that the resistor will not rotate about its axis.

- HR Mounting Style - Similar to “H” above except the horizontal feet are reversed. This is ideal for applications where space is at a premium.

Other Mounting Options

- Clips for Ferrule Ended Resistors - These clips are manufactured from Stainless Steel and are suitable for live or dead ferrule ended resistors.

- Push-In Mounting Brackets - Spring fit nickel plated phosphor bronze brackets for the ends of the tubular resistor provide an inexpensive method of mounting. They are available for PE 30, PE 40, PE 60L and PE 90L, but should not be used where rotation of the resistor in the clip is undesirable.

RESISTOR ENCLOSURES

Countinuous Power Ratings are available from 200 Watts to 7500 Watts. For pulse ratings, refer to the "Continuous & Intermittent" and "Continuous & Short Term" Power Rating tables below.

On this type of resistor, the power rating can be greater than that of the equivalent wire-wound resistor, due to the increased heat dissipation provided by the tape. We provide an option with Tape-wound resistor for an adjustable tapping clip. Thermal Cut-outs are mounted to some resistors to operate a contact to disconnect the resistor from the circuit preventing overload damage.

The minimum and maximum resistance values are below in a variety of standard resistance alloys. Upon request, we supply resistor in a Heavy-Duty Enclosure.

Power Ratings: Continuous, Short Term & Intermittent

| Power Ratings: Continuous, Short Term & Intermittent |

| Type |

Continuous |

Short Term (Seconds) |

Intermittent (Seconds) |

|

|

5 |

10 |

20 |

30 |

60 |

120 |

180 |

240 |

300 |

| BX40/200 |

200 W |

4000 W |

3000 W |

1800 W |

1100 W |

660 W |

500 W |

400 W |

300 W |

250 W |

| BX40/300 |

300 W |

6000 W |

4500 W |

2700 W |

1650 W |

990 W |

750 W |

600 W |

450 W |

375 W |

| BX40/400 |

400 W |

8000 W |

6000 W |

3600 W |

2200 W |

1320 W |

1000 W |

800 W |

600 W |

500 W |

| BX75/450 |

450 W |

9000 W |

6700 W |

4000 W |

2500 W |

1500 W |

1130 W |

900 W |

690 W |

570 W |

| BX75/600 |

600 W |

12300 W |

9200 W |

5500 W |

3200 W |

1930 W |

1460 W |

1170 W |

880 W |

740 W |

| BX75/750 |

750 W |

14700 W |

11000 W |

6600 W |

4000 W |

2420 W |

1830 W |

1460 W |

1100 W |

920 W |

| BX75/1000 |

1000 W |

20000 W |

15000 W |

9000 W |

5320 W |

3220 W |

2440 W |

1940 W |

1460 W |

1220 W |

| BX275/1500 |

1500 W |

29400 W |

22000 W |

13200 W |

8000 W |

4840 W |

3660 W |

2920 W |

2200 W |

1840 W |

| BX275/2000 |

2000 W |

40000 W |

30000 W |

18000 W |

10650 W |

6450 W |

4880 W |

3890 W |

2930 W |

2450 W |

| BX375/3000 |

3000 W |

58800 W |

44000 W |

26400 W |

16000 W |

9680 W |

7320 W |

5840 W |

4400 W |

3680 W |

| BX375/4000 |

4000 W |

80000 W |

60000 W |

36000 W |

21300 W |

12900 W |

9760 W |

7790 W |

5870 W |

4910 W |

|

|

Operating 1x Per Hour |

Operating Time in any 15 Minute Period |

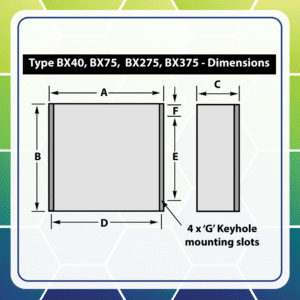

Resistor Enclosures – Dimensions

| Resistor Enclosures - Dimensions (mm) |

| Type |

A |

B |

C |

D |

E |

F |

G |

| BX40 |

182 |

300 |

133 |

168 |

208 |

38 |

4 |

| BX75 |

182 |

430 |

153 |

168 |

335 |

38 |

4 |

| BX275 |

510 |

315 |

187 |

495 |

225 |

40 |

5 |

| PBX375 |

510 |

500 |

187 |

495 |

410 |

40 |

5 |