ABOUT Silicon Metal Resistors

Silicon Metal Resistors are similar to ceramic composite resistors and have advantages in pulsed duty, requiring combinations of high peak power or high voltage with low inductance such as a precharge circuit. Silicon Metal Resistors have a much higher continuous temperature rating of 350°C as opposed to 250°C for ceramic resistors. This extended temperature range makes them suited for EV precharge circuits and inrush limiting applications that require a pre-charge resistor.

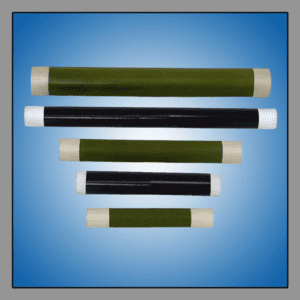

The simple construction consists of silicon and metal conductive particles dispersed throughout the element body, metal contacts on the ends of the body, and for high voltage resistor applications an anti-track coating. The resistive silicon metal element is manufactured using a specific mixture of materials suited to the bulk resistivity of the high energy resistor application.

Selection of the proper material resistivities in the composition mix varies among several options to allow the properties to be controlled and tailored to the high voltage resistor/ high energy resistors application. Once mixed, the material is granulated and pressed into the specific shape needed. This produces a high-temperature and electrically conductive bulk silicon metal linear resistor.

To produce the electrical contacts, aluminum, copper, or brass is flame sprayed onto the flat surfaces of the high energy resistors. In the case where connections are soldered to the metallization, the further addition of Sn, Zn, PD, Cu, Ag, Zr, and Co creates a metal surface that is electrically conductive and mechanically highly reliable.

For high energy resistor discs or high voltage resistor rods and tubes, an anti-track coating is applied to the edges to improve dielectric withstand.

A wide variety of geometries and range of resistivity can handle hundreds of Joules to Mega Joules of energy. These non inductive power resistors (ceramic resistors) are robust, having a constant mechanical strength, allowing for good compression specifications and the ability to absorb transmitted mechanical shock, as long as a direct impact is avoided.

Technical Advantage of Silicon Metal Resistors

Silicon Metal Resistors are ideal for applications that require a non inductive resistor to operate at high voltage providing high energy absorption, at an elevated temperature like those found in a precharge circuit resistor.

Compared to film or wire wound resistors where the resistive element is only a small fraction of the total mass of the component, the bulk construction of Silicon Metal Resistors concentrates most of the component mass into the resistive element allowing high energy events to be uniformly distributed through the entire mass of the material like similar to a carbon composition resistor or a ceramic resistor (ceramic composite resistor), there is no film or wire to fail. This bestows the capacity for high peak power and high reliability in pulsed or surge-prone duty.

Because 100% of the active material is conductive, it produces a high energy resistor with minimum size for pulse or high energy applications like a pre charge circuit. Bulk resistors are inherently non inductive resistors, and offer high energy density.

Compared to carbon composite resistors, ceramic composite resistors and Silicon Metal Resistors dissipate heat more rapidly, in the case of Silicon Metal Resistors and even higher average power can be tolerated. The high-temperature capability of the silicon resistor also allows much more energy density than carbon composition resistors and even ceramic resistors, which means smaller or fewer parts, resulting in better reliability and lowered cost.

Like ceramic resistors, Silicon Metal Resistors also exhibit better stability under extreme voltage and temperature. Like other "bulk" resistors, they are non inductive. This makes them ideal for pre-charge resistors in a precharge circuit for batteries or high-frequency applications.

Typical Silicon Metal Resistors Applications

- EV precharge resistor

- High-frequency Laser pulse application

- Capacitor discharge

- Non inductive resistor, non-capacitive as a load dump

- Amplifier applications require a non inductive power resistor.

- Precharge resistor circuit

- Generators and wind turbines as load dump

- Snubber Application

- Dummy load

- Overvoltage protection

- Precharge circuit for batteries

Silicon Metal Resistors Are Ideal For Under-Oil Use

Most resistive elements are not well suited for the combination of high voltage and high energy. When traditional resistive elements (wound or film type) are used under oil, high energies events result in large temperature rises in the conductive element. This high heat flux is difficult to dissipate due to the low surface area of the element. The high heat produced in these small elements also introduces the risk of oil degradation. In the case of Biodegradable oils, which are becoming more commonplace, they have higher moisture and can have more hydrocarbon gas dissolved in the oil. This can result in oil degradation affecting key thermal and electrical specifications.

Silicon Metal Resistors have a much lower temperature rise for a given high energy event, since 100% of the active material is conductive it allows energy and power to be uniformly distributed through the entire mass. The silicon metal linear resistor also has a much larger surface area allowing thermal energy to be more readily conducted into the oil. Performance under most oils is also well known.

SILICON RESISTOR - SI-METAL CERAMIC COMPOSITE RESISTORS

Silicon Metal Resistors (Si-Metal) are Silicon Metal Resistors that have 100% active material, extremely high surge energy rating, and provide an extended operating temperature greater than traditional ceramic composite resistors. These Siico resistors allow a continuous temperature rating of 350°C and a short duration temperature rating of 390°C. Our Silicon Metal Resistors are suited for Air, Oil and SF6 environments and applications which require high voltage withstand and high current density.

The unique construction of Silicon Metal Resistors allows for the highest continuous power rating and high energy absorption. Silicon metal linear resistor failures occur at 600°C and above. Common geometries of Silicon Metal Resistors are rods and tubes of varying sizes. As with other ceramic resistors and Silicon Metal Resistors may be connected in series or parallel for various total energy, electrical values, and power ratings.

Mechanical Parameters - Rod and Tube High Energy Resistors

| Description | Abbreviation | Range |

|---|---|---|

| Outside Diameter | Do | 10 to 50 mm |

| Inside Diameter | Di | 0 to 36 mm |

| Length | L | 50 to 600 mm |

| Density | N/A | 1.9 g / cm³ to 2.0 g / cm³ |

Electrical Parameters - Rod and Tube High Energy Resistors

| Item | Range |

|---|---|

| Operating Temperature Range | -40 to 350°C at full load, up to 370°C peak |

| Ohmic Range | 0.1 to 500 Ω/cm |

| Maximum Pulse Residual Voltage | 4.3 x 1.2√(log(R x A x l)) kV/cm |

| Specific Heat Capacity Approximately | 922 J/ (kg x K) |

| Inductance | nH’s (non-inductive) |

| Thermal Conductivity | 0.00424 W/ (cm² x K) |

| Outside Diameter | Inside Diameter | Maximum Length | Material Type | Maximum @ 20°C | Maximum @ 20°C | Maximum Pulse Voltage | Ohmic Range |

| mm | mm | mm | Abver | W | J | V | Ω |

| 18 | 8 | 50 | LT | 6 | 740 | 3500 | 250 to 10000 |

| 18 | 8 | 50 | MT | 15 | 1220 | 2800 | 50 to 500 |

| 18 | 8 | 50 | HT | 28 | 1770 | 2400 | 1.0 to 100 |

| 18 | 8 | 100 | LT | 17 | 149 | 9800 | 500 to 20000 |

| 18 | 8 | 100 | MT | 40 | 2450 | 8000 | 100 to 1000 |

| 18 | 8 | 100 | HT | 76 | 3550 | 7000 | 2.0 to 200 |

| 18 | 8 | 200 | LT | 39 | 2990 | 23100 | 1000 to 40000 |

| 18 | 8 | 200 | MT | 91 | 4910 | 18900 | 200 to 2000 |

| 18 | 8 | 200 | HT | 171 | 7110 | 16700 | 4.0 to 400 |

| Outside Diameter | Inside Diameter | Maximum Length | Material Type | Maximum @ 20°C | Maximum @ 20°C | Maximum Pulse Voltage | Ohmic Range |

| mm | mm | mm | Abver | W | J | V | Ω |

| 25 | 13 | 50 | LT | 9 | 1310 | 3300 | 150 to 6000 |

| 25 | 13 | 50 | MT | 21 | 2150 | 2600 | 30 to 300 |

| 25 | 13 | 50 | HT | 39 | 3110 | 2200 | 0.5 to 50 |

| 25 | 13 | 100 | LT | 24 | 2620 | 9200 | 300 to 12000 |

| 25 | 13 | 100 | MT | 56 | 4310 | 7500 | 60 to 600 |

| 25 | 13 | 100 | HT | 112 | 6230 | 6400 | 1.0 to 100 |

| 25 | 13 | 200 | LT | 54 | 5250 | 21700 | 600 to 24000 |

| 25 | 13 | 200 | MT | 127 | 8620 | 17800 | 120 to 1200 |

| 25 | 13 | 200 | HT | 238 | 12470 | 15500 | 2.0 to 200 |

| 25 | 13 | 300 | LT | 85 | 7880 | 34700 | 900 to 36000 |

| 25 | 13 | 300 | MT | 198 | 12930 | 28600 | 180 to 1800 |

| 25 | 13 | 300 | HT | 370 | 18710 | 24900 | 3.0 to 300 |

| 25 | 13 | 400 | LT | 115 | 11510 | 47900 | 1200 to 48000 |

| 25 | 13 | 400 | MT | 269 | 17240 | 39600 | 240 to 2400 |

| 25 | 13 | 400 | HT | 503 | 24950 | 34600 | 4.0 to 400 |

| Outside Diameter | Inside Diameter | Maximum Length | Material Type | Maximum @ 20°C | Maximum @ 20°C | Maximum Pulse Voltage | Ohmic Range |

| mm | mm | mm | Abver | W | J | V | Ω |

| 38 | 25 | 300 | LT | 129 | 14160 | 32600 | 700 to 30000 |

| 38 | 25 | 300 | MT | 301 | 23220 | 27000 | 150 to 1500 |

| 38 | 25 | 300 | HT | 563 | 33510 | 23700 | 3.0 to 250 |

| 38 | 25 | 450 | LT | 199 | 21240 | 51300 | 1100 to 45000 |

| 38 | 25 | 450 | MT | 463 | 34840 | 42700 | 225 to 2250 |

| 38 | 25 | 450 | HT | 865 | 50410 | 37500 | 4.5 to 375 |

| 38 | 25 | 600 | LT | 268 | 28320 | 70300 | 1400 to 60000 |

| 38 | 25 | 600 | MT | 625 | 46450 | 58700 | 300 to 3000 |

| 38 | 25 | 600 | HT | 1166 | 67220 | 51800 | 6.0 to 500 |

| Outside Diameter | Inside Diameter | Maximum Length | Material Type | Maximum @ 20°C | Maximum @ 20°C | Maximum Pulse Voltage | Ohmic Range |

| mm | mm | mm | Abver | W | J | V | Ω |

| 50 | 36 | 300 | LT | 146 | 20820 | 30900 | 500 to 20000 |

| 50 | 36 | 300 | MT | 340 | 34140 | 25600 | 100 to 1000 |

| 50 | 36 | 300 | HT | 635 | 49410 | 22800 | 1.5 to 200 |

| 50 | 36 | 450 | LT | 237 | 31230 | 48600 | 750 to 30000 |

| 50 | 36 | 450 | MT | 552 | 51210 | 40500 | 150 to 1500 |

| 50 | 36 | 450 | HT | 1032 | 74110 | 36100 | 2.25 to 300 |

| 50 | 36 | 600 | LT | 328 | 41640 | 66700 | 1000 to 40000 |

| 50 | 36 | 600 | MT | 765 | 68290 | 55700 | 200 to 2000 |

| 50 | 36 | 600 | HT | 1429 | 98820 | 49700 | 3.0 to 400 |