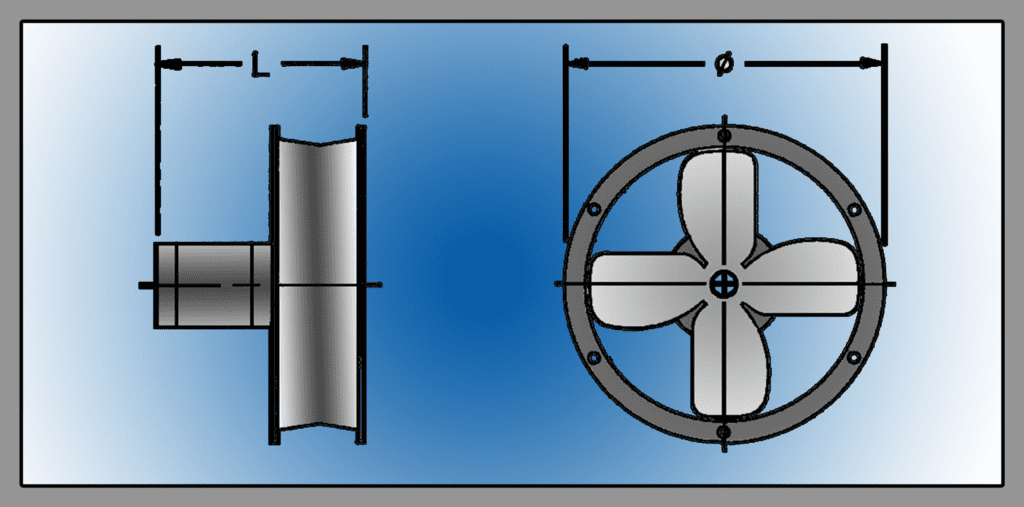

- Propeller Fan

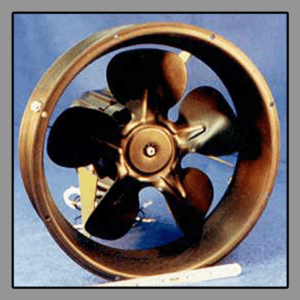

- Tubeaxial Fan

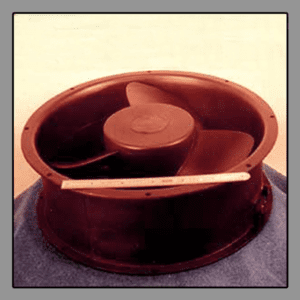

- Vane Axial Fan

- Axial Fans

- Radial Fan

- Cross Flow Blower

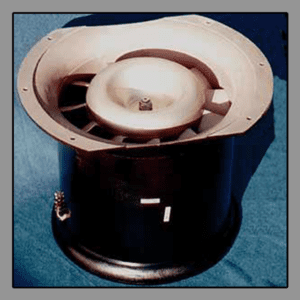

- Inverted Centrifugal Blower

- Multi Stage Centrifugal Blower

- Mixed Flow Fans

- Synchronous Motors

- Torque Motors

- Brushless DC Motors

- Stator and Rotor Sets

- Thermal Materials

- Heat Sinks

- Semiconductor Clamps

- Nanocrystalline Cores

ABOUT HIGH PRESSURE BLOWERS - AIR MOVERS - CENTRIFUGAL BLOWERS - FANS

Our high-performance air movers are custom-designed for a wide array of applications in the commercial and military markets. Air movers are for high static pressures and volumes of air where a typical off-the-shelf model will not meet your requirements. We specialize in providing a specific mechanical configuration, allowing customer selection of mounting, termination, and connector. We also provide these in various voltages frequencies and phases.

Providing more flow in a smaller space is especially important in airborne and defense systems which require; high flow rates, high pressure, high efficiency, and low noise. Our fans and blowers are manufactured in the USA since 1953. They are built to the following standards: MIL-I-45208 and MIL-Q-9858A. We provide solutions designed for high reliability and maintenance-free operation. In addition, they are tested to military standards for shock, vibration, temperature extremes, and harsh environments.

Our fans and blowers are used in various industrial, medical, aerospace, military, and railway applications. Railway applications include the locomotive power system: GenSet, Alternator, and DC chopper.

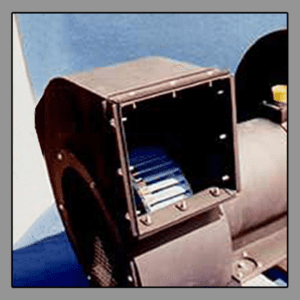

HIGH PERFORMANCE CENTRIFUGAL BLOWERS

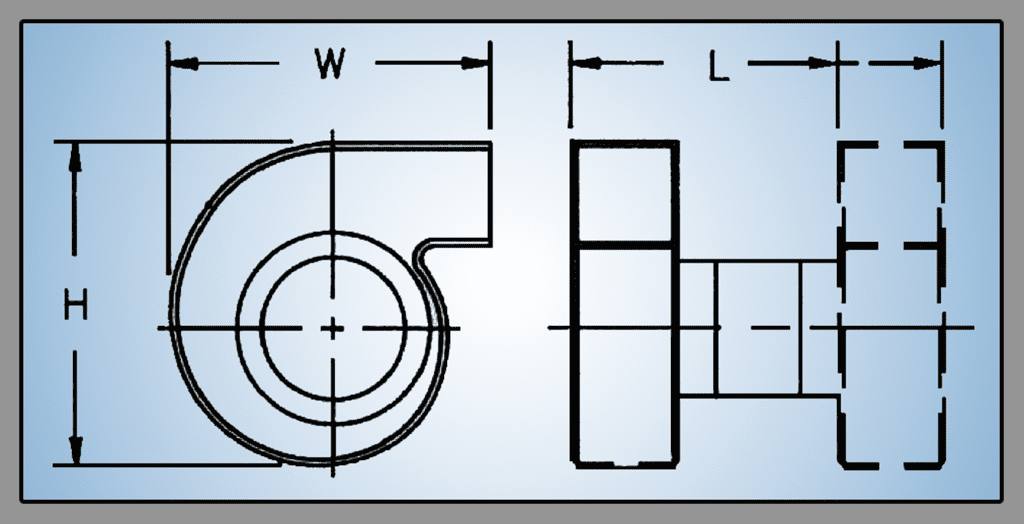

The housing of the centrifugal blower accelerates the air converting the kinetic energy into pressure. The output air is 90° to the air after entering the housing. Centrifugal blowers provide a high volume of airflow at moderate static pressures. These provide a constant volume or constant displacement such that, at a constant fan speed, a centrifugal blower moves a comparatively constant volume of air rather than a constant mass. The air velocity in a system is fixed even though the mass flow rate through the fan is not.

Centrifugal blowers are more efficient and are capable of operating over a wide range of conditions. Our centrifugal blowers are dynamically balanced and incorporate ball bearings to assure a long service life. These are available in Radial, Crossflow, Inverted, Single, and Duplex configurations. Backward impellers provide more pressure at less CFM. Squirrel cage designs provide moderate pressure at more CFM and a Radial Fan provides higher pressure at lower CFM. CFM at zero static pressure ranges from 10 to 4600 CFM. Operating Frequencies ranges from 50 to 400Hz.

Typical applications include cooling of:

- Defense: Electronics, communications equipment, ship board and airborne.

- Locomotive power systems: GenSet, Alternator and DC chopper.

- Transmitters: Broadcast and Satellite.

CENTRIFUGAL BLOWER DIAGRAM

FIVE TYPES OF CENTRIFUGAL BLOWER BLADES

- Backward curved blades - high-pressure, high flow, high efficiency

- Backward inclined blades - high operating efficiencies

- Air foil Backward inclined blades - highest efficiency with the lowest sound level

- Radial straight paddle blades - high-pressure fans with medium airflow

- Forward curved blades - medium pressure, high airflow

TYPES OF HIGH PERFORMANCE CENTRIFUGAL BLOWERS

- Radial Fan

- Cross Flow Blowers – Tangential Fans

- Inverted Centrifugal Blowers

RADIAL CENTRIFUGAL BLOWERS

This radial centrifugal blower/ motor assembly uses a radial blade design to provide high pressure to volume ratio and is particularly suitable for applications where compactness and lightweight are critical. These blowers are designed for extreme humidity, vibration, and shock for extended life and high-altitude conditions.

Our radial blade blowers feature higher pressures and superior performance in a compact design. These blowers are ideal for scavenging and locomotive bleed blower applications, ventilation of exhaust fumes, smoke exhaust, paint booth exhaust, and more. The self-cleaning wheels are ideal for systems where the air is laden with dirt, lint, or foreign material.

High-pressure applications are designed to choose the air blast direction and use single, multi, or variable speeds. We can provide a radial fan with various mounting configurations and motors to meet specific blower power requirements.

CROSS FLOW BLOWER - TANGENTIAL FAN

A cross flow blower or tangential fan provide a wide uniform high CFM delivery at moderate static pressure. As a result of a smaller impeller diameter to impeller length ratio, tangential fans have an extremely compact blower height and depth. The extremely shallow, flat design of tangential fans provide superior performance for their footprint. The large intake and outlet cross-section make it possible to achieve a high air throughput rate with low flow velocities.

Further characteristic features of a cross flow blower are; a long air throw, extremely low running noise, combinations of high air flow rates, and low back pressures or high air throughput with low flow velocities.

These cross flow blowers are dynamically balanced and incorporate ball bearings to guarantee a long service life. Expanded-width discharge area ensures that air makes good contact with ducts and surfaces to be cooled.

Tangential fans are ideal for:

- Air curtain

- Ventilation of exhaust fumes

- Uniform component cooling

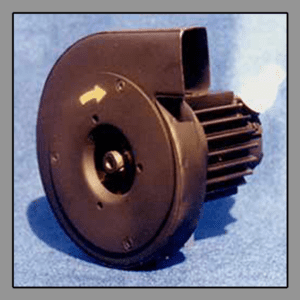

INVERTED CENTRIFUGAL BLOWERS

Our inverted centrifugal blowers take up less space than conventional centrifugal blowers and still provide high volumes of air at moderate static pressures. The drive motor of an inverted blower is located inside the squirrel cage wheel. Inverted centrifugal blowers provide exceptional compactness and excellent motor cooling.

Typical applications include cooling of electronics and communications equipment, cooling of television and radio, satellite broadcasting transmitters, air circulation for cooling, heating, and scavenging. They are dynamically balanced and incorporate ball bearings to guarantee a long service life.

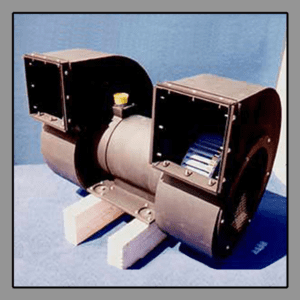

MULTI STAGE CENTRIFUGAL BLOWER

A multi stage centrifugal blower is a high static pressure blower. It produces very high static pressure at a low flow rate. Multi stage centrifugal blowers consist of multiple sets of impellers on the main shaft. The compression of air gradually increases as the air moves through each set of impellers.

The multi stage centrifugal blower relies on the kinetic energy of the air, or the increase in airflow speed to compress the air increasing the air pressure. The speed needed in a multi stage centrifugal blower can be much lower than a single stage centrifugal blower.

One application for a high pressure blower at a low flow rate is to produce a vacuum. Because of a multi stage centrifugal blower's ability to create a large amount of static pressure, a high static pressure blower is well suited for applications that may require suction, such as tape transport.

HIGH PERFORMANCE FANS

PROPELLER FANS

Pictured here is an example of a compact and lightweight high-performance propeller fan. It delivers a relatively high volume of air against a low static pressure. Because of this, the propeller fan is not well suited as a high pressure blower.

Propeller fans have a multi-bladed impeller directly driven by a motor mounted in the airstream. The airflow cools the motor, which is completely enclosed to keep out dust.

Our propeller fans have up to 16 blades, most common being 4 and 6 blades. We achieve greater efficiencies by using specially designed airfoil blade designs. These blade designs vary from round to square to rectangular. Rounded corner blades attain the highest volume and efficiency at the lowest audible noise level. It is also important to consider blade pitch angle in the overall propeller fan performance. In general, the greater the pitch angle, the slower the fan speed.

Typical applications:

- Cooling of Fresnel lens optical landing system on aircraft carriers and airfields.

- Electronic cabinet cooling.

AXIAL FANS

Axial fans consist of an impeller fitted with airfoil blades mounted on a rotating hub. Positioned in a cylindrical casing the hub is in line with the direction of airflow. Axial fans are named for the direction of the airflow they create. Airflow moves parallel to the fan, moving in a straight line through the fan.

Pitched blades rotating around an axis draw air in parallel to that axis and force air out in the same direction. Pitched blades are oriented at varying angles inside the fan to help create the pressure differential as the air moves through the fan. As the air moves, it makes contact with each blade, creating a pressure differential.

Axial fans create air flow with a high flow rate, meaning they create a large volume of airflow. However, the airflow they create are of low pressure. Axial fans are not intended for use in a high static pressure blower. They do however require a low power input for operation.

Our axial fans are designed to deliver high air volumes at relatively low pressures making them suitable for applications requiring a quiet operation. These fans are dynamically balanced and incorporate ball bearings to assure a long service life.

Typical applications:

- Electronics cooling

- Air movement across low density heat exchangers

TUBEAXIAL FANS

Tubeaxial fans use a propeller fan located in a short cylinder housing and flows is in the axial direction. These have efficient airfoil blades, close tip clearance, and a clean airflow pattern, providing high static pressure than the conventional propeller fan.

A tubeaxial fan provides higher air volumes at static pressure typically under 1”. Combined with our motor design capability, we have achieved high performance and efficiency at low noise levels. In general, a tubeaxial fan will produce less pressure than a vane axial fan.

They are ideal for enclosure installations needing a small footprint. Fans are dynamically balanced and incorporate ball bearings to guarantee a long service life.

Typical applications:

- Electronics cooling

- Air movement for heat exchangers

VANE AXIAL FANS

Vane axial fans provide efficient operation with straight-through airflow and minimal discharge vortex. They are designed with aerodynamically shaped impeller blades and incorporate specially designed straightening vanes to reduce air disturbances. We position the vanes either upstream or downstream of the impeller blades. Aerodynamically shaped impeller blades and straightening vanes result in higher pressures, increased efficiency, and lower noise levels. Vane axial fans provide high volumes of air at very high static pressure in a very compact space. Efficiencies of 70 to 80 percent are possible with fans used at a properly designed operating point.

The low weight to output ratio makes them well suited for airborne applications where higher pressure operation at high efficiency and lower noise levels are also important.

Electronics cooling with high air resistance or static pressure requirements involving high heat load dissipation will also benefit from vane axial fans. They are used extensively as condenser and evaporator fans for cabin environment heating and cooling systems.

Typical applications:

- Clean rooms

- Ground enclosures that use 50/60hz

- Aircraft for 400hz use

- Environmental cooling

- air circulation

MIXED FLOW FANS

Our mixed flow fans are more efficient than comparably sized vane axial fans, operating at high pressures and flow rates at reduced motor horsepower and noise levels.

These fans combine the desirable attributes of vane axial fans and centrifugal blowers in a straight-through airflow design. They are suited for use in a high pressure blower and are typically used in heat exchanger applications for the cooling or heating of personnel enclosures and spaces that house electronics as well as defense electronics applications.

STATOR AND ROTOR SETS

Stator and rotor sets enable the OEM to integrate the motor with its product, and are available in conventional and inside out designs, capable of operating at speeds in excess of 50,000 RPM.

Typical applications are gas, air, fluid film bearing spindles for machine tools, and infrared/laser line scanners where the motor and equipment must be built as an integral unit.

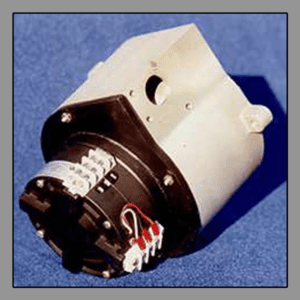

MOTORS

Our induction motors include a complete range of motors designed with various speed and torque characteristics to meet specific application requirements, and are manufactured to close tolerances with all rotating components balanced to provide longer bearing life and minimum noise and vibration.

Typical applications are fans and blowers, computer peripherals, pumps, aircraft equipment, and general drive applications.

INDUCTION MOTORS

Single, multi or variable speed, totally enclosed, open, ventilated, non-ventilated, single and double shaft extensions, flats, keyways or threaded extensions, metric or inch shaft extensions and mountings, lead configurations, connectors, junction boxes, special connection diagrams

TORQUE MOTORS

Single, multi or variable speed, totally enclosed, open, ventilated, non-ventilated, single and double shaft extensions, flats, keyways or threaded extensions, metric or inch shaft extensions and mountings, lead configurations, connectors, junction boxes, special connection diagrams

SYNCHRONOUS MOTORS

Single, multi or variable speed, totally enclosed, open, ventilated, non-ventilated, single and double shaft extensions, flats, keyways or threaded extensions, metric or inch shaft extensions and mountings, lead configurations, connectors, junction boxes, special connection diagrams

VALUE ADDED ASSEMBLIES

AC induction motors with glass optics used in laser scanners for optical inspection of sealing process in a bottling plant. A synchronous speed motor version is also available.Synchronous speed motor supplied with mirror optic for high-speed laser scanning application.

We can assist you in challenging applications when other suppliers feel the quantity/project potential is too low or application is too demanding.