ABOUT THERMAL INTERFACE MATERIALS

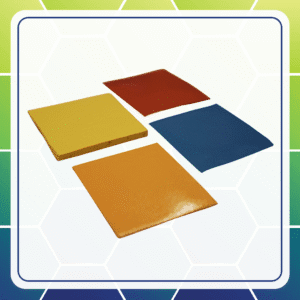

Our family of thermal management materials encompasses Thermal Interface Material, Gap Filler, Thermal Grease, and Graphite Films. These thermal materials allow a heat transfer thermal profile that is nearly free of loss. We can provide these thermal pads in a variety of forms to meet your thermal management needs.

The electronics industry is experiencing increasing demands for miniaturization and cost reduction. These size and cost reductions result in a dramatic increase in heat density. Miniaturization is achieved by using high-frequency topologies. These high-frequency topologies provide a reduction in the product size, along with designers adding enhancements to product functionality, leading to higher heat densities. This requires good thermal transfer materials to ensure product performance and longevity.

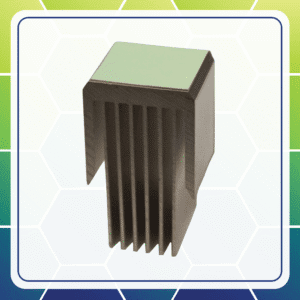

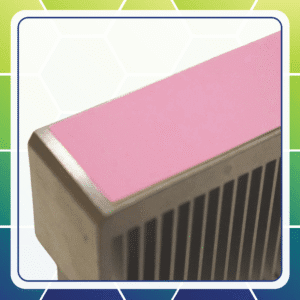

These thermal interface materials allow for the thermal coupling of heat-producing components and systems in an effective, uncomplicated, and cost-effective method of handling thermal management.

REDUCING MECHANICAL STRESS

Reducing mechanical stresses on the components assists both the designer in providing longer product life and the manufacturer in making the product easier to assemble. Hence our thermal interface materials and gap pads are designed to require low compression force for good thermal transfer, and in the case of the gap filler, offer the combination of extreme conformability and the ability to regain its original shape after compression forces are removed.

The products consist of highly flexible materials that are both thermally conductive and electrically insulating single or multi-component polymers, filled with ceramic or heat-conducting materials. In the case of graphite films, our Graphite thermal pads are also electrically conductive.

CERAMIC OR MICA DISCS MAY NOT BE REQUIRED

These heat-conducting thermal interface materials and gap pads can be mechanically reinforced by incorporating fiberglass or other materials and offer a versatile product that is superior in many aspects to conventional ceramic or mica discs.

Our thermal interface materials provide high thermal conductivity and good electrical insulation. In contrast to discs made of mica, aluminum, or polyamide, our thermal interface material can be used without a heat-conducting compound. We can also provide these as a finished die-cut thermal interface pad.

DO THERMAL INTERFACE MATERIALS DRY OUT DURING CONTINUOUS USE?

Compared to commonly used thermal grease, our interface materials do not dry out during continuous use, so they retain good thermal conductivity properties over several years.

Using these materials as opposed to thermal grease also eliminates issues such as smear, and when die-cut into a thermal interface pad they prevent component fitting errors. These thermal pads offer a clean alternative when replacing the thermal paste.

ADHESIVES ARE NOT ALWAYS NEEDED

Our heat-conducting films are made using a casting process that produces a smooth finish, facilitating component mounting due to their self-adhesive properties.

Not using adhesives in the assembly process allows for easier and cleaner component replacement; all that is required is the replacement of the thermal interface pad and issues with adhesive shelf life are eliminated. This provides an excellent alternative when replacing the thermal paste.

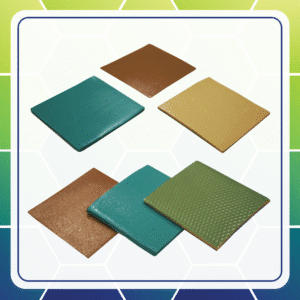

COMPRESSIBLE THERMAL INTERFACE MATERIALS -GAP FILLERS

These are soft, conformable low-tension thermal gap pads that do not have a memory. They are available in several thermal conductivities, thicknesses, and dielectric strengths. When used on high-frequency ferrite transformers or on surface-mount board applications, our thermal gap pads conform to different electronic component heights and housing irregularities, bridging the gap between these components and distortions of PCB.

This improves heat dissipation in a range of electronic assemblies, by minimizing the thermal resistance from the heat-producing components to the external surface of your products’ package or a heat sink.

Gap pads are electrically isolating, providing sufficient dielectric strength to withstand high voltages of your heat-producing component to a heat sink. They are strong and resist tearing and puncture from burs on the metal surface while maintaining maximum thermal performance.

These films have good dimensional stability to ensure controllability when used in a fully automated pick-and-place process. They can be supplied pre-cut in rolls or sheets.

Properties

- Highly flexible

- Outstanding compression

- Graduated thermal conductivity

- Good electrical insulation

- High-temperature stability

- Compensates for component size variations

- Optimized thermal transition

- Good compression behavior

- UL listed

- Optional single-sided adhesive surface

- Single-sided adhesive coating possible

- Can be supplied as sheets or already punched

COMPRESSIBLE THERMAL GAP FILLER – Datasheet

THERMAL INTERFACE MATERIALS -FILMS

Our standard thermal films are flexible and consist of a silicone elastomer, filled with various

thermo-conductive ceramic materials. All film types are electrically insulating and are resistant to water, oils and their mixtures, organic solvents, and chlorinated hydrocarbons, as well as the cleaning agents used to degrease and wash heat sinks, housings, and printed circuit boards.

For increased mechanical strength, the films are also available with fiberglass reinforcement. The standard films adapt to the component surface. Small irregularities can be evened out by using only minimal contact pressures.

The good thermal properties of these films guarantee optimum heat transfer to the heat sink and at the same time achieving

good electrical insulation properties. The film is available with optional single-sided adhesive coating, supplied on a roll and precut, and fiberglass reinforcement. We have a large number of standard shapes (TO, TIP, DO, and other power housing shapes), and can supply punch parts in customized shapes of any arbitrary size based on your drawings (maximum 400 x 400mm). Rolls can be supplied in widths of 15mm up to 500mm.

Benefits

- Smooth surface

- Very good thermal properties at very low contact pressure

- Low hardness

- High self-adhesion

- UL listed

- Good electrical insulation

- Heat-conducting

- Good compressibility

- Fully crosslinked

- Flexible

- Environmentally friendly

- RoHS conforming

- REACH conforming

Standard Thermal Films – Datasheet

THERMAL GREASE

Our thermal greases are ceramic-filled single-component silicones with high thermal conductivity for mounting to a heat sink. The non-cross-linked thermal compounds do not dry out. Silicone components will not leak from

the compound. Because of its viscosity, this homogeneous and thixotropic grease shows a very good fluidity allowing an optimum surface adaptation.

If needed we also offer a silicone-free thermal compound consisting of synthetic, thermal polymers

and suitable for fast and effective heat dissipation. The paste is particularly appropriate for silicone-sensitive applications. It has long-term stability which guarantees full operability during the entire lifetime of the product. Under normal application conditions the thermal grease and does not cure, dry out, or melt.

Available in:

- Syringes: 5 ml

- Cartridge Sizes: 75 ml / 310 ml / 360 ml

- Cans: 0.5 kg / 1.0 kg

Thermal Grease – Datasheet

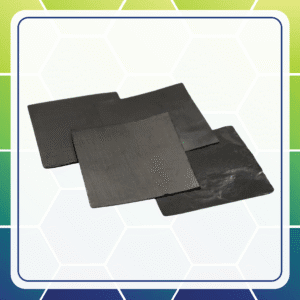

GRAPHITE FILMS

Our graphite film is made from high-density natural graphite with no binding materials. It is rolled and pressed into a film. It has exceptional thermal qualities with an x/y thermal conductivity of approximately 300W/mK and is a very cost-effective alternative to conventional thermal interface material.

It can provide a weight saving of up to 30% compared to conventional materials made of copper or aluminum. This makes these graphite thermal pads ideal for heat spreader applications, or applications in a vacuum, or at high temperatures (400°C). Note that graphite thermal pads have no electrical insulation, but can be customized and applied with an adhesive coating.

| Properties | Unit | High Density Graphite Foil |

|---|---|---|

| Color | Black | |

| Thermal resistance Rth | K/W | 0,037 |

| Thermal conductivity l | W/mK | 7.5 / >450 |

| (z-axis / x-y-axis) | ||

| Dielectric Breakdown Ud | KV | N/A |

| Total thickness (+/-10%) | mm | 0.13 |

| Density | g/cm³ | 1.8 |

| Application Temperature | °C | -40 to +500 |

| Hardness | Shore D | 25-35 |

| Flammability class | UL 94 | V 0 |

| TML | Ma % | 0.01 |