Standard Mercury Ultraviolet Lamps

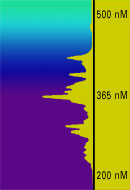

Mercury Spectrum

Metal Halide Lamp

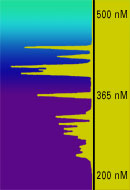

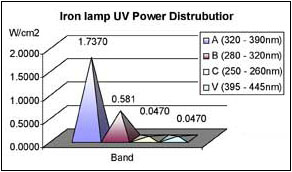

Iron Cobalt Spectrum

Iron Metal Halide Lamps and Operating Temperature

Iron metal halide lamps are extremely sensitive to over heating and need proper cooling . If the lamps are over heated for even a short period of time, iron is separated from the salt that is formed with the halogen and irreversibly fuses to the quartz. The iron part of the spectrum is now lost being unable to radiate.

There are three ways to tell if this has occurred:

- Check the spectrum to see if the 390nm peak is present using a spectrometer with the correct filter setting.

- Use a fluoroscope to check of stress fractures in the quartz.

- Visually check for white specks, this method is very difficult even for a experienced lamp technician.

Metal halide lamps are used in many types of applications whose photochemistry requires different UV wavelengths to initiate the photo-polymerization process. These come in either Gallium-Indium (GaI) or Iron-Cobalt (FeCo). Other additives are available upon request.

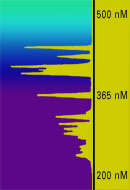

Gallium Indium Spectrum

Note that the Iron-Cobalt lamp has a broader spectrum with more spectral output in the 380 to 390nm region. The Gallium-Indium has an enhanced output in the 403 to 420nm region.

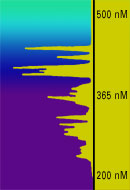

Another mix shown to the right is a multi-spectrum lamp, which is a mixture of Iron-Gallium producing an increased output over a broader region.

Multi Spectrum

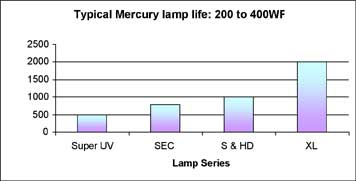

Extended Life UV Lamps

These UV bulbs typically have a useful life averaging between 2000 to 3500 hours with less than a ten percent ultraviolet drop off in UV energy. Long life is accomplished by a technologically advanced process of preparing and coating electrodes with a proprietary formulated emission material. In addition, the lamps are filled with a uniquely formulated inert gas along with a mixture of halogens. This results in a lamp with an identical ultraviolet spectral output at 365 nanometers but with a lower internal electrode temperature.

The combination of improved electrodes and the internal fill mixture results in a lamp which extends electrode life, therefore yielding a cleaner longer lasting lamp with less UV drop off. If you presently have a uv ballast and want to confirm the compatibility of extended life lamps, please fill in ballast operating and striking voltage in comments section of lamp RFQ form.

Mercury Spectrum

Super UV Lamps

These lamps radiate from twenty-five (25%) to one hundred (100%) percent more ultraviolet radiation at 365 nanometers (the standard mercury line) than standard mercury lamps. This only occurs at operation of 400 watts per inch or above. Lamps are manufactured with specially formulated electrodes and a unique metal halide compound.

Note: No additional electrical input power is required; lamps will operate on most standard mercury vapor ballasts. The lamps use a two millimeter quartz wall thickness (24 millimeter minimum outside diameter) and are warranted for 500 hours unconditionally. A typical 400 watt per inch Super UV lamp will equal or out-perform a standard 600 watt-per-inch mercury lamp while having the infrared radiation of a 400 watt-per-inch lamp.

Super UV Spectrum

Effect On UV Output by Varying Power Level

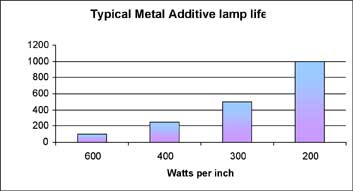

Efficiency vs. Watts per Inch

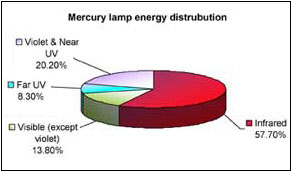

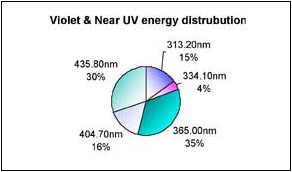

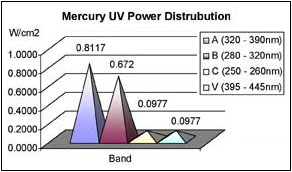

Mercury lamp output energy distribution

One of the most difficult units to quantify when investigating a bulb curing uv is mW/cm2 . This is used to determine the correct amount of UV energy necessary to cure your material properly. The material supplier may recommend a minimum amount of UV energy between 320 and 445nm. One way to get a very general approximation is to use the chart at the right in conjunction with the spectral information provided for the different uv curing lamps on this web site. For reference the Violet & Near UV (20.20 %)can be further broken down:

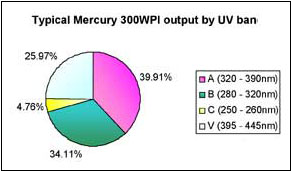

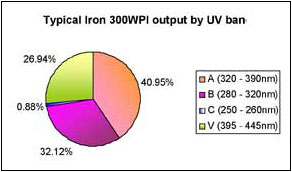

For reference a standard 300 watt-per-inch lamp using a typical focus assembly and a conveyor speed of from 40 to 60 feet per minute will have a UV power distribution shown below by band.

Here is the same data shown as a percentage: