UV Curing Lamp FAQUltraviolet curing for the new and experienced designer offers many challenges. We have compiled various facts, tips and definitions to assist the designer and user in understanding and applying these products to your own UV curing situation. If you have questions or comments we have not addressed, please send those to us.

UV FAQ’sWhat is an arc lamp and how does it work?An arc lamp consists of pressurized, sealed envelope containing gasses and/or metals with two electrodes, one at either end. A pulse of high voltage arcs the gap between the electrodes, (in early arc lamps the light emitting plasma was noted as bowing upwards in a curve or an arc, hence the name arc lamp). Heat from the arc vaporizes gases and/or metals in the envelope forming a plasma. This plasma generates light and UV energy. How do you calculate input current required by the ballast?Input current to ballast = [(NOMINAL WATTS / Power Factor) * (Power supply efficiency)] / Ballast input voltage Example: For: NOMINAL WATTS = 10,000 Gives: Input current to ballast = [( 10,000 / 0.92) * ( 0.90)] / 220 = 44.47 Amps How to measure lamp voltage?Since lamp voltages can exceed the safe measuring range of most meters a potential transformer (PT) is required. The PT is placed in parallel with the lamp. A typical 100:1 ratio is normally used. Measuring lamp voltage is one of the best ways to control lamp temperature in order to properly cool the lamp (link to cooling). How do I know at what power level I am operating?A current transformer is placed around the lamp lead wire allowing safe measurement of lamp current. Typical ratios used at 50:5A, 75:5A, 100:5 and 150:5A. (Place link to 2560 data sheet) How can I tell if a lamp is an additive lamp?If the lamp is not operating you will see a yellow brown deposit inside the lamp in addition to a bead of mercury for Gallium lamps. For iron additives you need to look very closely but metal like “filings” are visible on the inside of the lamp. You can also tell lamp type by looking at the color of the light when operational. NOTE you should never look directly or indirectly at reflected lamp light, as it is DANGEROUS. If you look at the “surrounding” area of the curing system it is possible to distinguish the color of different additives:

What is curling?Normally the arc plasma that occurs between the two electrodes of a lamp is approximately a straight line. When curling occurs the arc plasma instead of being a straight line forms a helix around the inside surface of the lamp causing the lamp to curl. The resonance that typically causes this curling effect occurs at arc lengths of 42″, 55″ and 77″ for 50Hz and between 38″ and 42″for additive lamps. Systems with these arc lengths should be avoided if possible. Ballast and lamp combinations can be configured to prevent this problem. Should I use an additive lamp?You need to ask your supplier of the UV material you are trying to cure. Ask them if additional UV energy in the 390nm or 420nm range will provide any benefit. Is Super UV right for me?Super UV effect only increases UV when operating lamp at above 400 WPI. Unfortunately there are no hard and fast rules on what works with different photo-initiators so empirical testing is required. Why does UV output fall off with lamp life?UV solarizes impurities in the lamp; Bromide is one example of an impurity. This solarization causes an output reduction of 15 to 20% in the first 20 hours of lamp operation. An additional reduction of 10% occurs in the next 100 hours. After 120 hours these transmission losses remain constant until lamp failure. Why do some lamps have a Gold coating near the electrodes?This gold plating in some cases helps to allow mercury trapped behind the electrode to vaporize; in most cases this coating is not required. Is there tolerance to lamp operating voltages?Typical lamp voltages can range from 3 to 6%, this range can sometimes vary as much as 10%. What causes this operating voltage range?Lamp voltage range is given because volume inside the quartz tube varies from lamp to lamp from when the quartz is drawn. This affects the concentration of gases in the lamp, which in turn affects lamp voltage. Wattage and current increasing and no change to lamp voltage seems counter intuitive to Ohms law, what is going on?Initially there is no voltage drop across lamp, but as the pressure builds in the lamp voltage increases. This voltage then remains roughly constant through the whole wattage range. A ballast power supply is designed to be current limiting; the addition of capacitive reactance to this circuit increases lamp current and total wattage since lamp voltage is constant. What is the typical time required for a lamp to come up to full power?Lamp start up time is typically 1 to 5 minutes Note that lamp must cool down to allow mercury to re-condense before restart. What is the silver colored bead inside the lamp?This is mercury. When high voltage from a ballast is applied to the lamp mercury inside the lamp is energized into plasma where it generates specific wavelengths of ultraviolet energy, which are used to initiate the polymerization of UV curable inks and Can a higher-powered lamp be used in our existing curing system?Power supplies and UV lamps are usually designed and matched to provide peak performance. The lamp is cooled in a specially designed lamp irradiator assembly, which should provide an appropriate cooled environment for reliable lamp operation. Usually, upgrading Can a standard lamp be replaced with an additive lamp to enhance UV output?A metal halide lamp will enhance output in specific spectrums. If the material you are using is responsive to those additional spectrums you will see a benefit. Note that the power supply must be capable of supplying the correct operating voltage to initiate the arc and have the correct waveform to maintain the arc. What would cause the ballast capacitor to catastrophically fail?Over cooling a lamp can sometime have this effect. In most cases when you over-cool a lamp it will extinguish but under certain circumstances the lamp will hover just above extinguishing level noticeably oscillating or pulsing. If you were to use an oscilloscope you will notice voltage spikes, these spikes over stress the capacitors eventually resulting in capacitor failure. What if my lamp will not light when power is applied?

What if my substrate is not properly curing?

What if my lamp is bowed?A bowed lamp should be replaced immediately along with evaluation of the lamp cooling system. This condition is a direct result of improper lamp cooling. The lamp must be controlled where the surface temperature is between 600 – 800 degrees C. If the air around the lamp is not properly controlled, this temperature will rise causing the quartz tube to soften and lose its rigidity. Adjust the cooling and airflow around the lamp to reduce the temperature of the lamp body. However, ensure that the lamp body is not cooled below 600 degrees C, as below this temperature could lead to mercury condensing out of the plasma, which will effect lamp power and performance. What if my lamp is discolored?Discoloration can occur for several reasons. There is natural “blackening” of the quartz tube at each end during the life of the lamp. This is the result of the electrode material depositing on the inside of the tube during its use. Discoloration of the quartz will occur over time due to natural solarization or “clouding” of the quartz. This occurs as the quartz reverts to its natural crystalline structure, which is opaque to ultraviolet energy. Discoloration may also occur if the lamp is overcooled. This action results in mercury being deposited on the inside of the lamp giving a mirror-coated affect. What if the outside edges of my substrate are not curing?If this is occurring in existing system where this problem has not occurring before, check for darkening at the lamps ends which could reduce light output. Note that there is a natural optical roll off of UV output at the end of the lamp in a refectorized What if my lamp initially lights, flickers and then extinguishes?There are many possibilities, a few to consider:

Do metal halide lamps have special cooling requirements?Gallium and multi-spectrum lamps have cooling requirements fairly equivalent to mercury lamps. Special care is required for iron lamps. If an iron lamp overheats, the iron will irreversibly become part of the quartz tube. This will not cause lamp failure but you will lose the iron portion of the UV spectrum. Is the ballast connected properly?A simple test to see whether the ballast is connected up correctly is to directly connect the capacitor lead to the lamp lead and measure the current through this wire. The ballast is current limiting, if it is wired correctly on the primary side this current should be 1.5 times lamp current. Different manufacturers have names for the spectrum their lamps produce, this is confusing.

|

|

Type |

Actual Spectrum |

| H | Standard mercury |

| D | Iron Cobalt Spectrum |

| V | Gallium Indium |

What can cause lamp-operating voltage to change?

Lamps running too hot can expand causing a drop in the running voltage and a reduction in output.

FAQ’s for LIA’s

- How much longer is the LIA than the arc of the lamp?

- How do I install the LIA?

- Are these available with shutters?

- Do the LIA’s require any maintenance?

- How are lamps replaced?

- Do I need UV shielding for my LIA?

How much longer is the LIA than the arc of the lamp?

* Overall length is approximately 10 to 11 inches longer than the lamp arc length.

|

Part Number |

Lamp Arc Length |

Irradiator Length |

|

HIR1004 |

4.00″ |

14.06″ |

|

HIR1006 |

5.31″ |

16.75″ |

|

HIR1008 |

8.00″ |

18.93″ |

|

HIR10012 |

12.47″ |

23.71″ |

|

HIR10018 |

18.47″ |

29.28″ |

|

HIR10025 |

25.47″ |

36.28″ |

|

HIR10030 |

30.47″ |

41.28″ |

|

HIR10038 |

38.47″ |

49.28″ |

|

HIR10042 |

42.00″ |

52.81″ |

|

HIR10048 |

48.47″ |

59.28″ |

|

HIR10050 |

50.00″ |

60.81″ |

|

HIR10055 |

55.87″ |

66.68″ |

|

HIR10060 |

60.47″ |

71.28″ |

|

HIR10065 |

65.00″ |

75.81″ |

|

HIR10077 |

77.46″ |

88.28″ |

* Above chart lists a few of our LIA’s.

How do I install the LIA?

Installation instructions

- The irradiator can be mounted by using 8-32 screws in the pre-drilled holes on the irradiator making sure that all of the vents have unrestricted airflow. Failure to provide free airflow will result in overheating of the irradiator and/or lamps.

- The focal point is located 2.5 inches from the face of the irradiator.

- A qualified electrician must make electrical connections. The two lamp leads are made of silicon insulated wire and are to be connected to the ballast according to the manufacturer’s specifications

- Fan leads need to be connected to specified voltages.

- Fans may require a time delay of 1 to 1.5 minutes to allow for lamp startup.

- Connect the interlock leads as a safety switch to the power supply. They will indicate open or closed state of the irradiator (shuttered version only).

Are these available with shutters?

Yes, an air cylinder powered shutter is a standard option. Air pressure that you supply is required for operation. Air pressure requirements are different for each size. This information will be included with your order.

Do the LIA’s require any maintenance?

Yes, the irradiator will require routine cleaning due to the large amount of air being circulated. Accumulations of dust on the cooling fins and around the vents should be removed routinely. Failure to do so will result in overheating and component failure. Accumulations of dust around the electrical connections will result in arcing and can be extremely hazardous.

How are lamps replaced?

Lamp Replacement procedure:

- A qualified person following proper lockout procedures must perform lamp replacement.

- Turn power off. Be sure that the irradiator and lamp have cooled before removing the lamp.

- Disconnect all power and high voltage cable from the LIA.

- Remove irradiator cover by removing both knobs at each end of the LIA and lifting out the assembly by its handles.

- Place the LIA upside down on its handles

- Remove one metal diffuser. Loosen the screws on the lamp holder to release the top bracket.

- Disconnect the lamp leads and pull lamp out of the LIA.

- Clean the replacement UV lamp and reflector liners with a lint free cloth and denatured isopropyl alcohol. Use latex or vinyl gloves during this step to keep the lamp free of any fingerprints.

- Place one lamp lead and end fitting through the mounted metal air diffuser and on top of the lamp holder. Place the loose metal air diffuser around the other lamp end and place the lamp end onto the lamp holder.

- Remount the metal air diffuser and place the top bracket over the lamp end and tighten the top bracket.

- Connect lamp leads to ceramic standoffs.

- Place the irradiator back in place and tighten the four knobs and reconnect the high voltage cable by matching index to index and screwing the connector cable down completely.

Do I need UV shielding for my LIA?

LIA’s emit ultraviolet radiation, which is harmful to the eyes and skin. Precautions should be taken to protect personnel from exposure of direct or reflected radiation. Personnel should use suitable eye and skin protection. We offer a light gauge metal shielding which is capable of blocking ultraviolet radiation. Remember that one third of the energy emitted by the lamp is in the infrared range and fireproof material should always be used.

Definitions of UV terms

Halide – A binary compound of a Halogen with a more electropositive element or radical i.e. iron, cobalt, gallium, iodide.

Halogen – Consists of one of these five elements: Fluorine, Chlorine, Bromine, Iodine, Astatine.

Arc Length – This is measured in full inches. For example, lamps 15.4 inches and below are priced as 15-inch lamps; 15.5 inches and above are priced as 16 inch, etc.

HD – Lamps designated as HD (heavy duty) are made from thicker-walled quartz than standard lamps. Ideally, the thinnest wall quartz should be used to provide maximum UV output. An added benefit is that the lamp is less expensive. However, there is always a compromise, which in this case is physical strength and heat. By their nature, very long lamps and lamps of 500 watts per inch (wpi) or higher must be made from HD material, and are automatically handled as such. In addition, some systems are prone to overheating, and it is not always possible to treat the cause of the problem by reducing the lamp environment temperature. So in some cases, HD material is selected for its ability to operate acceptably with hot equipment. There is no hard and fast rule; experience will determine which applications require HD lamps

O/F – Ozone-Free lamps are made with special quartz.

Additive – This category includes any additive lamp, including iron

Quartz – Basic silicon diode that has a specific gravity of 265 and hardness of 7. Natural quartz has a melting point of 783 degrees C. When quartz is processed it is changed to a form called tridymite quartz and the melting temperature increases to 1470 degrees C.

Ampere – (A) The constant current that, if maintained in two straight parallel conductors of infinite length and negligible cross section and separated from each other by a distance of 1 meter in a vacuum, will produce in these conductors a force equal to 2 X 10 -7 Newton/meter.

Angstrom – A unit of length equal to 10 – 10 meter. Usually the measurement of wavelengths or frequencies of the electromagnetic spectrum.

Atmosphere – A unit of pressure. One standard atmosphere equals 101,325 newtons per square meter.

Devitrification – When the quartz envelope of a lamp is subject to high temperatures it will become porous and eventually allow lamp atmosphere to fail.

Mercury Lamp – Lamp

in which light is generated through presence of mercury vapor. Most UV

lamps are mercury vapor lamps.

Nanometer – A unit of distance commonly used in measuring wavelength in the electromagnetic spectrum-one billionth of a meter.

Nominal Watts – Arc length * Watts per inch (WPI)

Photoinitiator – A molecule which when expressed to a specific wavelength of energy forms a reactive species which starts the chain reaction to cause formation.

Photosensitizer – A chemical which will transfer energy and form free radicals by interacting with another chemical.

Photopolymer – A composition which will either crosslink or depolymerize on exposure to light, forming a physical differentiation between the exposed and unexposed portion.

Plasma – A vapor in which there are energetic free radicals, ions, or molecules. These are usually formed by radio frequency discharge.

Polymer – A macromolecule consisting of an indefinite number of monomer units. The molecular weights may range from about 20,000 into the millions.

Quartz Tube – A lamp made from a silicate material called quartz which is fitted with electrical connections to form an irradiator. It may be made into an infrared emitter or it may be filled with mercury vapor to produce ultraviolet light.

Substrate – The unfinished product upon which a finishing (e.g., coating, ink, or adhesive) is placed.

Stabilizers – Additives to coatings, inks, or adhesives formulations which help extend shelf life, resistance to heat or other degradation.

Ultraviolet Light UV – That light emitted in the 200-400nm wavelength range.

UV Lamp Life

Normal lamp life is 1000 to 3000 hours and under optimal conditions can be up to 4000 hours. Our lamps typically have longer life because of the superior materials used and construction. We use quartz capillaries to attach to the quartz envelope. A lamp that uses glass capillaries to attach to the quartz envelope can have a short life because the dissimilar materials have slightly different CTE (coefficient of thermal expansion). These joints are a weak link in lamp construction.

Three main items affect Lamp Life

- Number of Starts

- Maintaining correct cooling

- Proper lamp installation.

Number of Starts

Starts refer to the number of times a lamp is turned completely on and off. The pressure in lamp atmosphere changes when the lamp is under full power, which mechanically stresses the lamp. There are other mechanical stresses caused by Thermal cycling of the lamp components. Another reason number of starts affects lamp life is the introduction of tungsten and small amounts of other materials from the electrodes each time the lamp is ignited. This contamination when introduced into the lamp atmosphere can effectively increase lamp open Circuit voltage, making it more difficult to operate the lamp. If possible start lamps in high power to reduce the length of time the lamp is in the starting mode. Note: Excessive starts cause premature darkening of the ends and a drop in output.

Maintaining correct cooling

See Lamp cooling section for details on monitoring lamp characteristics for maintaining the correct cooling. Periodic maintenance of the cooling system will also help to extend lamp life, this includes:

- Keeping the reflectors clean

- Making sure reflectors are free of distortion from caused by heat from the lamp

- Cleaning dirt on the blower blades, this blocks air flow and reduces the cooling efficiency.

Proper lamp installation.

Proper lamp installation includes the following:

- Avoid finger oil on the lamp body by using a paper towel or glove. Using an alcohol wipe is recommended to assure clean surfaces.

- Maintain good electrical connections.

- Allow flexibility when mounting. The lamp should not be held tightly in place. This can restrict movement as the reflectors expand, and contract during operation.

Lamp Cooling

For medium pressure UV lamps to operate properly the envelope must be at a rather high temperature 700 to 850C and at the same time the end seals/fittings must be kept cool (250 to 300C). This can be physically measured by using a temperature probe. A K-type probe, with Kromel-Alumel wire rated for 1250C. are available from several sources such as Omega Engineering . One of the best ways to check for over cooling or under-cooling of a lamp is to monitor lamp voltage. Lamp voltage should stay with in

+/-10% of nominal operating voltage. If the voltage drops below 10% then you are over cooling the lamp, if it exceeds 10% you are under-cooling the lamp. A potential transformer (PT) is used for this measurement (link). Most power supplies are current limiting devices so an increase or decrease in the operating voltage will not necessarily change lamp current. Lamps that are over cooled will show a telltale blackening of the inside of the quartz near the ends of the lamp. Lamp temperature ranges for optimal life

|

Part of Lamp |

Optimal Temp |

Effect of Improper Cooling |

| Capillary | 250 to 350 C | Ceramic paste on the end fitting will crack, Molybdenum foil oxidizes and causes the seals to fracture. |

| Lamp envelope | 650 to 800 C | Quartz will devitrify allowing the lamp atmosphere to escape. Devitrification can also occur if lamps are improperly handled. |

| Lamp envelope | 900C | Quartz softens lamp bowing and deformation. |

| Electrode reflector | 1000 C | Gold Melts |

| End-fittings | 1100 C | For lamps that use stainless steel they discolors. |

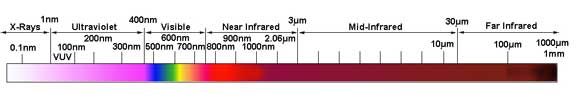

The Electromagnetic Spectrum

The light that is perceptible to the human eye is in the range of 400 to 750nm. Red is roughly 700nm, green 550nm and blue is 450nm. For an overview perspective below you will see a wavelength spectrum from X-ray to Far Infrared.

Wavelength Spectrum

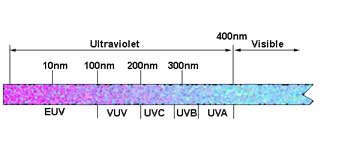

Ultraviolet Spectrum Ultraviolet falls in the spectrum below blue and refers to all electromagnetic radiation with wavelengths in the range of 10-400 nanometers. The Ultraviolet spectrum is further broken up in to UVA, UVB, UVC, VUV and EUV.

Ultraviolet Spectrum

UVA range is wavelengths from 315-400 nanometers. Part of the UVA spectrum from approximately 340-380nm is used for “Blacklight” (this causes fluorescent objects to glow) and actually is slightly visible to the human eye if isolated from more visible wavelengths. The other portion of the UVA spectrum wavelengths from 320-380nm are used for standard UV curing, NDT (non-destructive testing and inspection. UVB range is wavelengths from 280-315 nanometers and is typically used in sun tanning. These wavelengths are actually more dangerous to the skin and eyes than UVA and are mainly responsible for sunburn. UVC range is wavelengths from 200-280 nanometers and has applications in Dermatology. VUV wavelengths range from 100-200nm “Vacuum” UV these wavelengths are absorbed by air are used for various space, and scientific applications and are often even used for germ killing. EUV is from 10 to 100nu and is the least explored of all UV wavelengths.

The UV Curing Process

UV Curing is a photochemical process by which monomers harden or cure (polymerize or cross-ink) upon exposure to ultraviolet radiation. A specifically formulated monomer will polymerize when exposed to ultraviolet light. This UV “curable” monomer includes a sensitizer, which absorbs UV energy and initiates a polymerizing reaction in the monomer

Five main components UV Curing System

- UV source, lamp

- ILIA (irradiator) or reflector assembly

- Ballast (Power Supply)

- Electrical controls including current and potential transformers

- Safety equipment for shielding