- Single-Phase CM Nanocrystalline Cores

- Three-Phase CM Nanocrystalline Cores

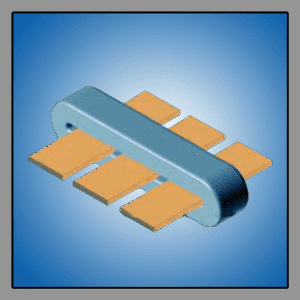

- CM Chokes using Nanocrystalline Cores

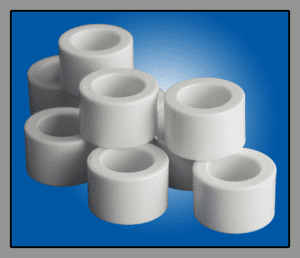

- Spike Absorbing Cores

- Surge Absorbers Beads

- Surge Absorbers Leaded Beads

- High Frequency Low Loss Transformers Cores

- Nanocrystalline C-Cores Sets

- Nanocrystalline Block Cores

- How Nanocrystalline Ribbon is Made

ABOUT COMMON-MODE CHOKES

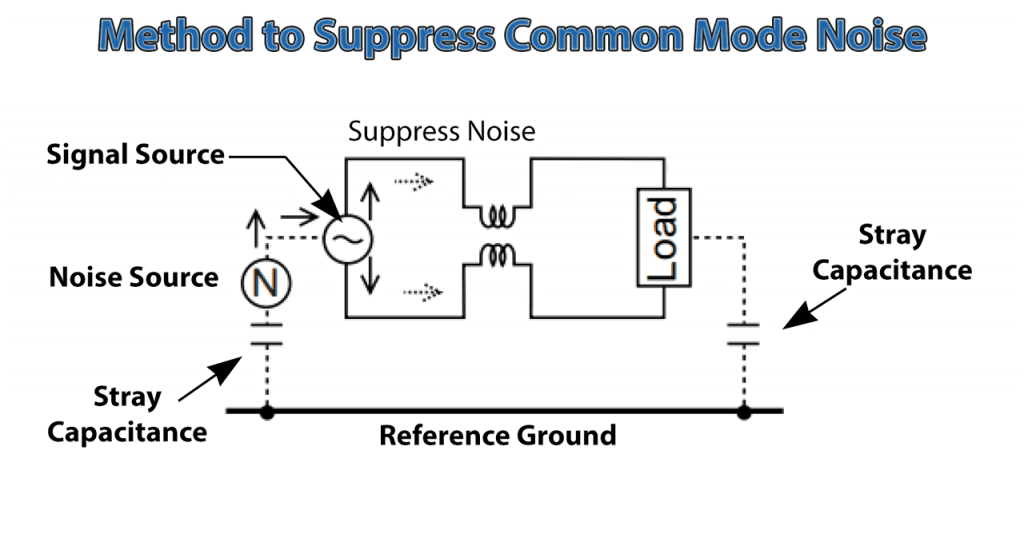

Common mode choke coils block undesirable high-frequency noise typically from unshielded electronics, inverters, and motors. This noise can simultaneously come from both input sides (line and neutral) and also radio signals; whose radiated signals can induce additional undesirable noise currents.

The selection of the proper core material for common mode choke coils is the main contributor to creating an effective common mode choke. Cores made of amorphous ribbon similar to Metglas® that is field annealed into Nanocrystalline ribbon have three times higher impedance at 3MHz than that of Mn-Zn Ferrite and can be much smaller and weigh significantly less. For example, an Mn-Zn ferrite rated at 20A and an impedance of 3mH at 100kHz using a Nanocrystalline core will weigh 47% less and be 45% smaller.

Common mode chokes made with Nanocrystalline cores tend to have the highest impedance in the frequency bandwidths which tend to be the most problematic to pass Electromagnetic Interference (EMI) and Electromagnetic Compatibility (EMC) testing. Nanocrystalline material is also extremely stable over temperature. APPLICATIONSCommon mode chokes constructed with Nanocrystalline cores provide significant size and weight reductions. This along with high noise attenuation in the frequency bandwidth needed, make these components especially well-suited for applications such as:

- DC Charging Stations

- Traction Inverters

- Extremely Fast Vehicle Charging (XFC)

- Energy Storage Inverters

- Medium-and Heavy-Duty Electric Vehicle Charging

- Wireless High-Frequency Charging

- High-Performance Hybrid Electric Vehicles (HEVs)

COMMON MODE CHOKE COILS AND CORES MADE WITH NANOCRYSTALLINE MATERIAL

Common Mode Chokes (CMC) made with Nanocrystalline material have superior characteristics when compared to the most commonly used material Mn-Zn ferrite.

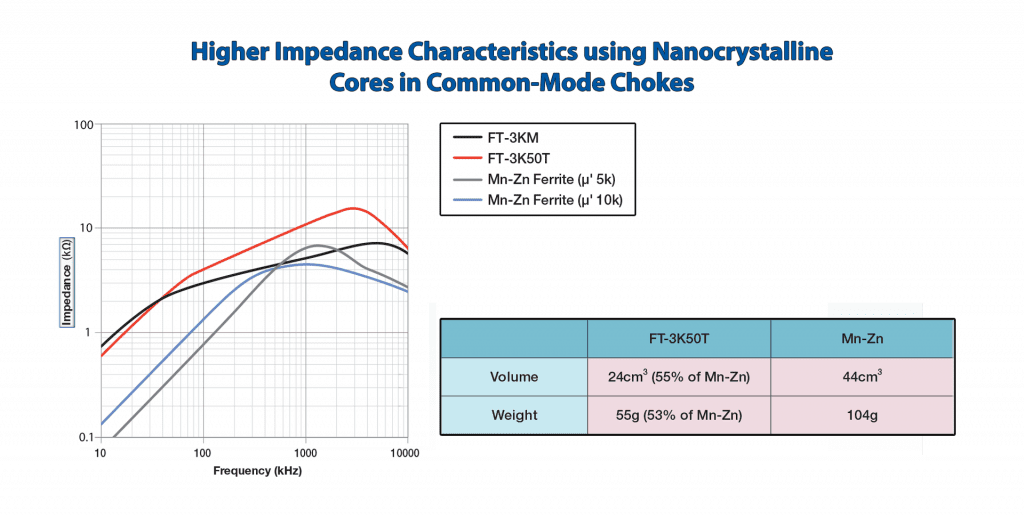

Higher Permeability The potential of designing smaller common mode choke coils (CMC) with the same number or fewer turns is of interest to many designers. Nanocrystalline materials offer this possibility by providing a complex permeability (µr at 100kHz and 20°C), which is more than twice that of Mn-Zn ferrite. The impedance relative permeability (µrz) is more than four times as high as Mn-Zn ferrite. In one case, this allows the designer using Nanocrystalline material to use a core of identical size to Mn-Zn ferrite, which will produce a four times higher impedance with the same number of turns. In another case, the designer can use this material to reduce the windings by ½ and to obtain the same low-frequency impedance, significantly reducing stray capacitance and as a result, the high-frequency impedance also becomes large. The below charts show the higher impedance benefit of field-annealed nanocrystalline cores versus Mn-Zn ferrite.Comparison of magnetic and physical properties between FINEMET® and Mn-Zn ferrite

|

FT-3KL |

FT-3KM |

Mn-Zn ferrite | ||

| Initial permeability at 100 kHz µr’ | 20° C | 17,000 | 17,000 | 5,300 |

| 100° C | 15,000 | 18,000 | 7,000 | |

| Impedance permeability at 100 kHz µrz | 20° C | 18,500 | 26,900 | 5,300 |

| 100° C | 16,000 | 27,100 | 7,000 | |

| Saturation magnetic flux density Bs* (T) | 20° C | 1.23 | 1.23 | 0.44 |

| 100° C | 1.20 | 1.20 | 0.27 | |

| Residual magnetic flux density Br* (T) | 20° C | 0.06 | 0.62 | 0.10 |

| 100° C | 0.04 | 0.59 | 0.06 | |

| Coercive Force Hc *(A/m) | 20° C | 0.6 | 2.5 | 8.0 |

| 100° C | 0.6 | 2.7 | 4.9 | |

| Curie temperature Tc (°C) | 570 | 570 | 150 | |

| Saturation magnetostriction λs (x106) | ~0.0 | ~0.0 | -1.1 | |

| Electrical resistivity ρ(µΩ.m) | 1.2 | 1.2 | 1.0x106 | |

| Density d(kg/m3) | 7.4x103 | 1.27.3x103 | 4.85x103 | |

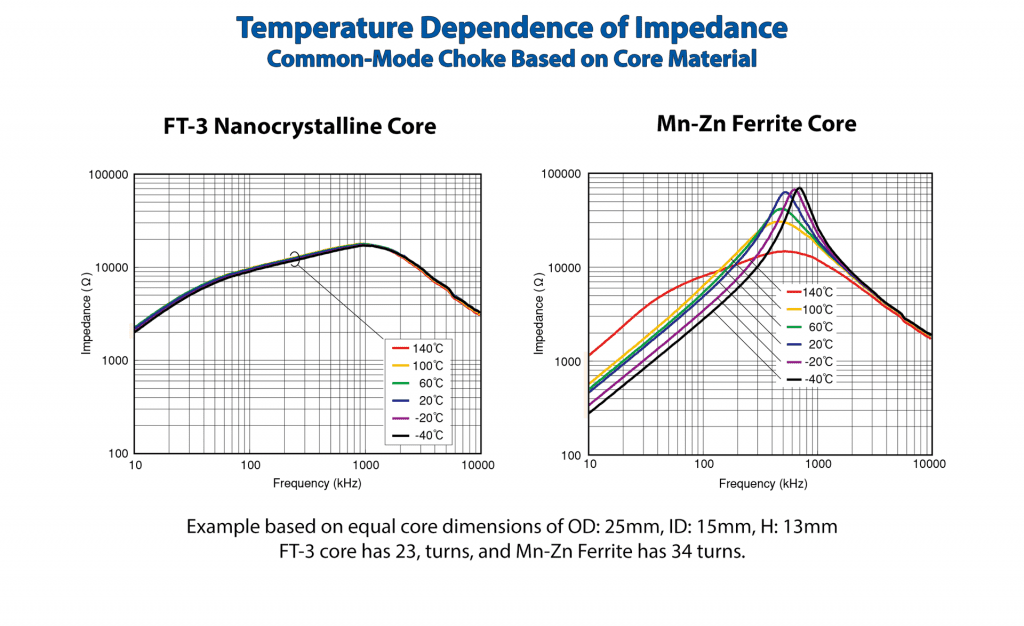

The temperature has little effect on permeability

Another concern to many designers is the temperature dependence of many materials used for common-mode chokes (CMC) designs. Often, larger cores with more turns are used to compensate for temperature drift. Nanocrystalline material’s frequency characteristics of impedance are not significantly affected by temperature change. As a result, it offers high noise suppression performance over a wide temperature range.

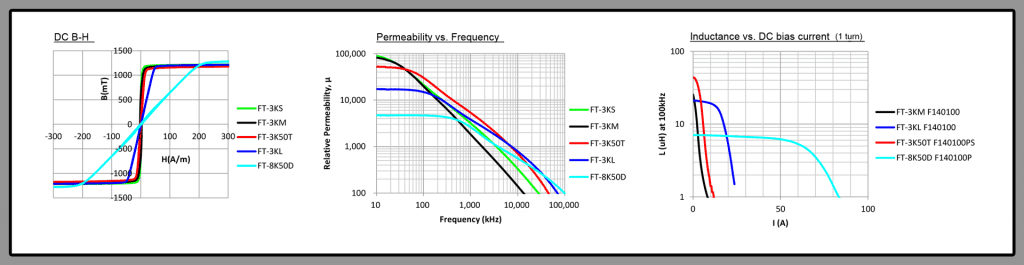

FINEMET® FT-3K50T AND FT-8K50D

These are the latest and most advanced materials produced by applying a controlled magnetic field during annealing to industry-leading thin nanocrystalline ribbon, which is much thinner than amorphous ribbon such as Metglas®. This provides a material that satisfies both high saturation magnetic flux density and high permeability.

MATERIAL PROPERTIES

| Material | Bsat(T)) | Permeability at 10kHz | Permeability at 100kHz | Br/Bs | Saturation magnetostriction, λs (X 10^-6) | Coercive force, Hc (A/m) |

|---|---|---|---|---|---|---|

| FT-3KS | 1.23 | 100,000 | 20,000 | 40 | 1 | 15 |

| FT-3KM | 1.23 | 70,000 | 15,000 | 50 | 1 | 2.5 |

| FT-3K50T | 1.23 | 50,000 | 31,000 | 10 | 1 | 1.2 |

| FT-3KL | 1.23 | 27,000 | 17,000 | 5 | 1 | 0.6 |

| FT-8K50D | 1.32 | 5,000 | 5,000 | 0.7 | 8 | 1.4 |

NANOCRYSTALLINE PERFORMANCE CURVES

FT-3K50T F SERIES -TOROIDAL CORE

| Product Code | P/N | Finished Dimensions (mm) | AL value (µH/n2) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| A | B | C | Ac (mm2) TYP | Lm (mm) TYP | Weight (g) TYP | 10 kHz MIN | 100 kHz ±30% | ||

| F1AH1157 | FT-3K50T F1613YS | 17.8 | 8.0 | 10.7 | 45.2 | 7.9 | 4 | 7.7~14.3 | 6.4±30% |

| F1AH1181 | FT-3K50T F2117DS | 23.3 | 15.3 | 13.9 | 18.9 | 59.6 | 11 | 14.7~27.3 | 12.0 ± 30% |

| F1AH1182 | FT-3KM50T F2515DS | 28.5 | 17.5 | 12.3 | 44.3 | 93.3 | Upgrade your common mode chokes with Nanocrystalline material, 3x higher impedance at 3MHz, 47% lighter & 45% smaller common mode choke coil designs.25 | 30.7~65.9 | 27.2 ± 30% |

| F1AH1183 | FT-3K50T F3020CS | 33.1 | 13. | 17.4 | 37.6 | 79.3 | 28 | 21.6.4~40.2 | 179.9 ± 30% |

| F1AH1107 | FT-3K50T F3320ES | 36.3 | 18.2 | 16.8 | 71.2 | 83.3 | 49 | 37.6~80.6 | 33.3 ± 30% |

| F1AH1108 | FT-3K50T F3724ES | 40.5 | 18.3 | 20.6 | 71.2 | 60 | 49 | 33.9~62.9 | 28.1 ± 30% |

| F1AH1184 | FT-3K50T F4032ES | 42.3 | 17.8 | 29.1 | 43.8 | 113.0 | 40 | 16.1~29.8 | 14.2 ± 30% |

| F1AH1185 | FT-3K50T F4424GS | 47.1 | 23.4 | 21.0 | 138.8 | 106.8 | 123 | 57.1~122.4 | 50.6 ± 30% |

| F1AH1109 | FT-3K50T F4535GS | 49.5 | 25.7 | 30.5 | 73.0 | 141.0 | 80 | 22.6~49.9 | 20.0 ± 30% |

| F1AH1186 | FT-3K50T F4627HS | 50.7 | 29.2 | 22.9 | 173.4 | 114.7 | 164 | 66.5~142.5 | 58.9 ± 30% |

| F1AH1187 | FT-3K50T F5040GD | 52.3 | 22.8 | 37.1 | 73.0 | 141.0 | 80 | 22.6~49.9 | 20.0±30% |

| F1AH1110 | FT-3K50T F6045GS | 64.7 | 26.0 | 40.3 | 104.4 | 166.0 | 162 | 27.6~59.2 | 24.4 ± 30% |

| F1AH1111 | FT-3K50T F7555GS | 79.7 | 25.7 | 50.3 | 142.3 | 205.0 | 267 | 30.5~49.9 | 27.1±30% |

| F1AH1112 | FT-3K50T F10080GS | 104.7 | 25.7 | 75.3 | 138.8 | 285.1 | 336 | 20.9~44.7 | 18.5±30% |

| F1AH1113 | FT-3K50T F140100PS | 145.0 | 36.0 | 95.3 | 4275.5 | 380.1 | 1335 | 49.5~106 | 43.8±30% |

FT-8K50D F SERIES - TOROIDAL CORES

| Product Code | P/N | Finished Dimensions (mm) | AL value (µH/n2) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| A | B | C | Ac (mm2) TYP | Lm (mm) TYP | Weight (g) TYP | 10 kHz MIN | 100 kHz ±30% | ||

| F1AH1121 | FT-8K50D F4535G | 49.5 | 25.7 | 30.5 | 75.0 | 125.7 | 89 | 3.7 ± 30% | 3.7 ± 30% |

| F1AH1122 | FT-8K50D F6045G | 64.7 | 26.0 | 40.3 | 107.3 | 166 | 157 | 4.1 ±30% | 4.0 ± 30% |

| F1AH1123 | FT-8K50D F7555G | 79.7 | 25.7 | 50.3 | 146.3 | 200.5 | 272 | 4.5 ± 30% | 4.4 ± 30% |

| F1AH1124 | FT-8K50D F10080G | 104.7 | 25.7 | 75.3 | 139.5 | 286.2 | 336 | 3.1 ± 30% | 3.0 ± 30% |

| F1AH1125 | FT-8K50D F140100P | 145.0 | 36.0 | 95.3 | 430.9 | 382.8 | 1350 | 7.1 ± 30% | 7.0 ± 30% |

| F1AH1164 | FT-8K50D F160130H | 166.9 | 30.5 | 123.9 | 292.5 | 455.5 | 1029 | 4.0 ± 30% | 4.0 ± 30% |

| F1AH1126 | FT-8K50D F200160P | 205.0 | 36.0 | 155.0 | 427.5 | 568.6 | 1930 | 4.7 ± 30% | 4.7 ± 30% |

Download EMC brochure for information on common mode components:

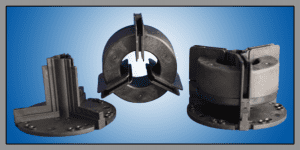

LARGE NANOCRYSTALLINE COMMON MODE INDUCTOR CORES

If you require much larger cores for common mode chokes with rated currents over 100Amps, these cores offer you the size to solve RF noise problems.

They can be used for signal lines, DC power lines, and AC power lines. Because of the low magnetostriction, these cores also provide low audible noise. Cores with base plates only require cabling with the appropriate BIL insulation for the voltage being used. L-type cores are used when a DC offset is present, see BH curves.FT-3KM F SERIES - NANOCRYSTALLINE "M TYPE" TOROIDAL CORES

| Product Code | P/N | Finished Dimensions (mm) | AL value (µH/n2) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| A ±0.7 | B ±0.7 | C ±0.7 | Ac (mm2) TYP | Lm (mm) TYP | Weight (g) TYP | 10 kHz MIN | 100 kHz ±30% | ||

| F1AH0047 | FT-3KM F2515D | 28.0 ± 0.5 | 16.8 + 0.7 | 12.8 + 0.5 | 46.9 | 62.8 | 25 | 42.0~100.0 | 16.9 + 30% |

| F1AH1139 | FT-3KM F3020C | 31.0 ± 0.5 | 13.0 ± 0.7 | 17.4± 0.5 | >38.2 | 78.9 | 28 | 29.8~55.4 | 11.0 + 30% |

| F1AH0048 | FT-3KM F3320E | 35.8 ± 0.5 | 17.5 ± 0.7 | 17.3 ± 0.5 | 73.1 | 83.3 | 49 | 49.7~120.0 | 19.9 ± 30% |

| F1AH0049 | FT-3KM F3724E | 49.0 ± 0.5 | 17.6 ± 0.7 | 21.1 ± 0.5 | 73.1 | 95.8 | 59 | 43.0~100.0 | 17.3 ± 30% |

| F1AH1140 | FT-3KM F4032E | 42.0 | 17.0 | 29.0 | 40.8 | 111.6 | 40 | 22.5~41.8 | 8.3 ± 30% |

| F1AH0050 | FT-3KM F4424G | 46.5 ± 0.5 | 22.8 ± 0.6 | 21.1 ± 0.5 | 142.5 | 106.8 | 123 | 75.4~180 | 30.2 ± 30% |

| F1AH0896 | FT-3KM F4535G | 49.0 ± 0.5 | 25.0 ± 0.7 | 31.0 ± 0.5 | 75.0 | 125.7 | 89 | 34.0~80.0 | 13.5 ± 30% |

| F1AH0897 | FT-3KM F4627H | 50.0 ± 0.7 | 28.2 ± 1.0 | 23.4 ± 0.5 | 178.1 | 114.7 | 168 | 89.2~210.0 | 35.1 ± 30% |

| F1AH0898 | FT-3KM F6045G | 64.0 ± 0.7 | 25.0 ± 1.0 | 41.0 ± 0.7 | 112.5 | 164.9 | 162 | 39.0~90.0 | 15.4 ± 30% |

| F1AH0899 | FT-3KM F7555G | 79.0 ± 0.7 | 25.0 ± 0.7 | 51.0 ± 0.7 | 150 | 204.2 | 267 | 42.0~100.0 | 16.6 ± 30% |

| F1AH0900 | FT-3KM F10080G | 104.0 ± 0.7 | 25.0 ± 0.7 | 76.0 ± 0.7 | 138.8 | 285.1 | 336 | 30.0~65.0 | 12.0 ± 30% |

| F1AH0901 | FT-3KM F140100 | 144.0 ± 1.0 | 35.0 ± 1.0 | 96.0 ± 0.7 | 427.5 | 380.1 | 1335 | 24.8 ± 30% | 24.8 ± 30% |

| F1AH0024 | FT-3KM F200160 | 204.0 ± 1.0 | 35.0 ± 1.0 | 156.0 ± 1.0 | 427.5 | 568.6 | 1875 | 42.0~100.0 | 15.1+50%,-30% |

M-type cores with base and base plate combined

| Product Code | P/N | Finished dimensions in mm | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| A Max | B Max | C Max | D ±0.5 | E ±0.3 | F ±0.5 | G ±0.5 | H ±0.5 | K Min | ||

| F1AH0026 | FT-3KM F6045GB | 95.0 | 26.0 | 78.0 | 80.0 | 12.5 | 72.0 | 50.0 | 7.0 | 39.5 |

| F1AH0027 | FT-3KM F7555GB | 121.0 | 30.0 | 100.0 | 100.0 | - | - | - | - | 50.0 |

| F1AH0053 | FT-3KM F10080GB | 161.0 | 32.0 | 122.0 | 140.0 | - | - | - | - | 75.0 |

| F1AH0029 | FT-3KM F11080GB | 181.0 | 26.0 | 131.0 | 150.0 | 12.5 | 124.0 | 100.0 | 20.0 | 74.0 |

| F1AH0031 | FT-3KM F140100PB | 181.0 | 42.0 | 162.0 | 160.0 | - | - | - | - | 95.0 |

| F1AH0032 | FT-3KM F200160PB | 241.0 | 42.0 | 217.0 | 220.0 | - | - | - | - | 155.0 |

| Product Code | P/N | Ae (mm2) Typical | Lm (mm) Typical | Weight (g) Typical | Applied Screw | AL value(µH/N2) | Shape | ||

|---|---|---|---|---|---|---|---|---|---|

| I | J | 10kHz | 100kHz | ||||||

| F1AH0026 | FT-3KM F6045GB | 112.5 | 164.9 | 193.0 | M4 | M5 | 39.0 ~ 90 | 15.4 ±30% | Combined |

| F1AH0027 | FT-3KM F7555GB | 150.0 | 204.2 | 377.0 | - | - | 42.0 ~ 100 | 16.6 ±30% | Base Plate |

| F1AH0053 | FT-3KM F10080GB | 138.8 | 285.1 | 516.0 | - | M6 | 30.0 ~ 65 | 12.0 ±30% | Base Plate |

| F1AH0029 | FT-3KM F11080GB | 213.8 | 300.8 | 613.0 | M5 | M6 | 40.2 ~ 95 | 16.1 ±30% | Combined | Upgrade your common mode chokes with Nanocrystalline material, 3x higher impedance at 3MHz, 47% lighter & 45% smaller common mode choke coil designs.

| F1AH0031 | FT-3KM F140100PB | 427.5 | 380.1 | 1595 | - | M6 | 63.0 ~ 150 | 24.8 ±30% | Base Plate |

| F1AH0032 | FT-3KM F200160PB | 427.5 | 568.6 | 2235 | - | M6 | 42.0 ~ 100 | 15.1 +50%,-30% | Base Plate |

FT-3KL F SERIES- NANOCRYSTALLINE "L TYPE" TOROIDAL CORES

| Product Code | P/N | Finished Dimensions (mm) | AL value (µH/n2) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| A | B | C | Ac (mm2) TYP | Lm (mm) TYP | Weight (g) TYP | 10 kHz MIN | 100 kHz ±30% | ||

| F1AS3249 | FT-3KL F2515D | 28.5 ±0.5 | 17.5 ±0.7 | 12.3 ±0.5 | 46.9 | 62.8 | 25 | 14.5 ~ 27.0 | 15.3 ±30% |

| F1AS3250 | FT-3KL F3020C | 33.1 ±0.5 | 13.0 ±0.7 | 17.4 ±0.5 | 37.6 | 79.3 | 28 | 9.7 ~ 18.5 | 10.5 ±30% |

| F1AH0680 | FT-3KL F3320E | 35.8 ±0.5 | 17.5 ±0.7 | 17.3 ±0.5 | 73.1 | 83.3 | 49 | 17.8 ~ 33.0 | 18.8 ±30% |

| F1AH0681 | FT-3KL F3724E | 40.0 ±0.5 | 17.6 ±0.7 | 21.1 ±0.5 | 73.1 | 95.8 | 59 | 15.4 ~ 28.7 | 16.3 ±30% |

| F1AS3251 | FT-3KL F4032E | 42.3 ±0.5 | 17.8 ±0.7 | 29.1 ±0.5 | 43.8 | 113.0 | 40 | 6.5 ~ 17.5 | 8.9 ±30% |

| F1AS3252 | FT-3KL F4424G | 47.1 ±0.5 | 23.4 ±0.7 | 21.0 ±0.5 | 142.5 | 106.8 | 123 | 23.0 ~ 54.2 | 28.5 ±30% |

| F1AH0682 | FT-3KL F4535G | 49.0 ±0.5 | 25.0 ±0.7 | 31.0 ±0.5 | 75 | 125.7 | 89 | 12.1 ~ 22.4 | 12.8 ±30% |

| F1AS2799 | FT-3KL F4627H | 50.7 ±0.7 | 29.2 ±0.7 | 22.9 ±0.5 | 178.1 | 114.7 | 168 | 34.1 ~ 54.4 | 33.2 ±30% |

| F1AS3253 | FT-3KL F5040G | 52.3 ±0.7 | 22.8 ±0.5 | 37.1 ±0.7 | 73.0 | 141.0 | 80 | 9.9 ~ 18.4 | 11.0 ±30% |

| F1AH0683 | FT-3KL F6045G | 64.0 ±0.7 | 25.0 ±1.0 | 41.0 ±0.7 | 107.3 | 166 | 162 | 13.1 ~ 24.3 | 13.8 ±30% |

| F1AH0684 | FT-3KL F7555G | 79.0 ±0.7 | 25.0 ±0.7 | 51.0 ±0.7 | 146.3 | 205 | 267 | 14.4 ~ 26.8 | 15.2 ±30% |

| F1AH0685 | FT-3KL F10080G | 104.0 ±0.7 | 25.0 ±0.7 | 76.0 ±0.7 | 138.8 | 285.1 | 336 | 9.8 ~ 18.3 | 10.4 ±30% |

| F1AH0686 | FT-3KL F140100 | 144.0 ±1.0 | 35.0 ±1.0 | 96.0 ±0.7 | 427.5 | 380.1 | 1335 | 22.8 ~ 42.3 | 24.0 ±30% |

| F1AS3254 | FT-3KL F200160 | 205.0 ±1.0 | 35.0 ±1.0 | 155.0 ±0.7 | 427.5 | 568.6 | 1875 | 14.4 ~ 26.8 | 16.1 ±30% |

L-type core with base and base plates combined

| Product Code | P/N | Dimensions in mm | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| A Max | B Max | C Max | D ±0.5 | E ±0.3 | F ±0.5 | G ±0.5 | H ±0.5 | K Min | ||

| F1AH0687 | FT-3KL F6045GB | 95.0 | 26.0 | 78.0 | 80.0 | 12.5 | 72.0 | 50.0 | 7.0 | 39.5 |

| F1AH0688 | FT-3KL F7555GB | 121.0 | 30.0 | 100.0 | 100.0 | - | - | - | - | 50.0 |

| F1AH0691 | FT-3KL F140100PB | 181.0 | 42.0 | 162.0 | 160.0 | - | - | - | - | 95.0 |

| Product Code | P/N | Ae (mm2) Typical | Lm (mm) Typical | Weight (g) Typical | Applied Screw | AL value (uH/N2) | Shape | ||

|---|---|---|---|---|---|---|---|---|---|

| I | J | 10kHz | 100kHz | ||||||

| F1AH0687 | FT-3KL F6045GB | 107.3 | 166.0 | 193.0 | M4 | M5 | 13.1 ~ 24.3 | 13.8 ±30% | Combined |

| F1AH0688 | FT-3KL F7555GB | 146.3 | 205.0 | 377.0 | - | M6 | 14.4 ~ 26.8 | 15.2 ±30% | Base plate |

| F1AH0690 | FT-3KL F11080GB | 213.8 | 300.8 | 613.0 | M5 | M6 | 14.4 ~ 26.7 | 15.2 ±30% | Combined |

| F1AH0691 | FT-3KL F140100PB | 427.5 | 380.1 | 1595.0 | - | M6 | 22.8 ~ 42.3 | 24.0 ±30% | Base plate |

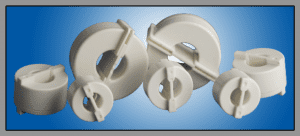

SINGLE-PHASE CORES

For the designer interested in winding an inductor for a specific application we have available the following standard cores for single-phase common mode choke coils requirements. These are toroidal-shaped tape-wound cores made from nanocrystalline amorphous metal.

These cores are inserted into a protective plastic case made from a UL94 V-0 certified resin (130℃: PBT, 155℃: PET heat resistance). The case has built-in winding separators to add in creepage and dialectic isolation requirements. The below table lists; Product code and part number for cores made with FT-3KM material and the new FT-3KM50T upgraded version of FT-3KM.FT-3K50T - K SERIES

| Product Code | P/N | Finished Dimensions (mm) | Ac (mm2) TYP | Lm (mm) TYP | Wt (g) TYP | AL value (µH/n2) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A ±0.7 | B ±0.7 | C ±0.5 | D ±0.7 | E REF | F REF | G REF | 10kHz MIN | 100kHz ±30% | |||||

| F1AH0538 | FT-3KM K1208A | 13.0 | 7.1 | 6.0 | 10.7 | 2.6 | - | 1.8 | 7.7 | 30.3 | 2.9 | 18.2 | 5.8 |

| F1AH0692 | FT-3KM K1208C | 13.5 | 12.5 | 6.8 | 15.5 | 3.2 | - | 1.5 | 13.3 | 31.7 | 4.5 | 24.0 | 8.8 |

| F1AH0654 | FT-3KM K1812A | 20.2 | 8.1 | 10.3 | 13.1 | 3.5 | - | 2.5 | 11.3 | 47.1 | 5.8 | 14.7 | 5.3 |

| F1AH0693 | FT-3KM K1912C | 21.1 | 13.3 | 10.0 | 18.3 | 3.5 | - | 2.5 | 24.4 | 48.9 | 13.0 | 28.2 | 10.6 |

| F1AH0694 | FT-3KM K2313D | 25.2 | 15.1 | 11.5 | 20.7 | 3.5 | - | 2.8 | 43.9 | 57.3 | 23.0 | 41.6 | 15.3 |

| F1AH0695 | FT-3KM K2214B | 24.2 | 10.6 | 12.0 | 16.2 | 4.0 | - | 2.8 | 22.2 | 56.5 | 13.0 | 22.2 | 8.1 |

| F1AH0696 | FT-3KM K2515D | 27.2 | 15.6 | 13.0 | 21.2 | 3.5 | - | 2.8 | 46.3 | 62.8 | 26.0 | 41.6 | 15.3 |

| F1AH0697 | FT-3KM K2818E | 30.4 | 18.0 | 15.8 | 24.0 | 3.5 | 1.5 | 3.0 | 55.5 | 72.3 | 37.0 | 43.4 | 15.9 |

| F1AH0699 | FT-3KM K3819D | 40.4 | 15.5 | 16.8 | 23.5 | 4.0 | 2.0 | 4.0 | 87.9 | 89.5 | 68.0 | 55.5 | 20.4 |

| F1AH0700 | FT-3KM K3824G | 40.6 | 23.0 | 21.4 | 31.0 | 4.0 | 2.0 | 4.0 | 105.0 | 97.4 | 87.0 | 61.0 | 24.4 |

| F1AH0701 | FT-3KM K5328E | 56.4 | 19.0 | 24.6 | 29.0 | 5.5 | 2.0 | 5.0 | 127.5 | 114.7 | 155.0 | 62.5 | 25.0 |

FT-3KM - K SERIES

| Product Code | P/N | Finished Dimensions (mm) | Ac (mm2) TYP | Lm (mm) TYP | Wt (g) TYP | AL value (µH/n2) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A ±0.7 | B ±0.7 | C ±0.5 | D ±0.7 | E REF | F REF | G REF | 10kHz MIN | 100kHz ±30% | |||||

| F1AH1128 | FT-3K50T K1208AS | 13.7 | 7.8 | 5.5 | 11.4 | 2.6 | - | 1.8 | 7.7 | 30.3 | 2.9 | 16.6 | 10.3 |

| F1AH1129 | FT-3K50T K1208CS | 14.2 | 13.2 | 6.3 | 16.2 | 3.0 | - | 1.5 | 13.3 | 31.7 | 4.5 | 26.9 | 16.7 |

| F1AH1130 | FT-3K50T K1812AS | 20.9 | 8.8 | 9.8 | 13.8 | 3.5 | - | 2.5 | 11.3 | 47.1 | 5.8 | 13.2 | 8.2 |

| F1AH1131 | FT-3K50T K1912CS | 21.8 | 14.0 | 9.5 | 19.0 | 3.5 | - | 2.5 | 24.4 | 48.9 | 13.0 | 32.6 | 20.2 |

| F1AH1132 | FT-3K50T K2313DS | 25.9 | 15.8 | 11.0 | 21.4 | 4.0 | - | 2.8 | 43.9 | 57.3 | 23.0 | 50.8 | 31.5 |

| F1AH1133 | FT-3K50T K2214BS | 24.9 | 11.3 | 11.5 | 16.9 | 4.0 | - | 2.8 | 22.2 | 56.5 | 13.0 | 25.8 | 16.0 |

| F1AH1134 | FT-3K50T K2515DS | 27.9 | 16.3 | 12.5 | 21.9 | 3.5 | - | 2.8 | 46.3 | 62.8 | 26.0 | 46.9 | 29.1 |

| F1AH1135 | FT-3K50T K2818ES | 31.1 | 18.7 | 15.3 | 24.7 | 3.5 | 1.5 | 3.0 | 55.5 | 72.3 | 37.0 | 49.0 | 30.4 |

| F1AH1136 | FT-3K50T K3819DS | 41.1 | 16.2 | 16.3 | 24.2 | 4.0 | 2.0 | 4.0 | 87.9 | 89.5 | 68.0 | 62.5 | 38.7 |

| F1AH1137 | FT-3K50T K3824GS | 41.3 | 23.7 | 20.9 | 31.7 | 4.0 | 2.0 | 4.0 | 105.0 | 97.4 | 87.0 | 67.4 | 41.8 |

| F1AH1138 | FT-3K50T K5328ES | 57.1 | 19.7 | 24.1 | 29.7 | 5.5 | 2.0 | 5.0 | 127.5 | 114.7 | 155.0 | 71.1 | 44.1 |

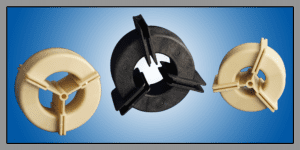

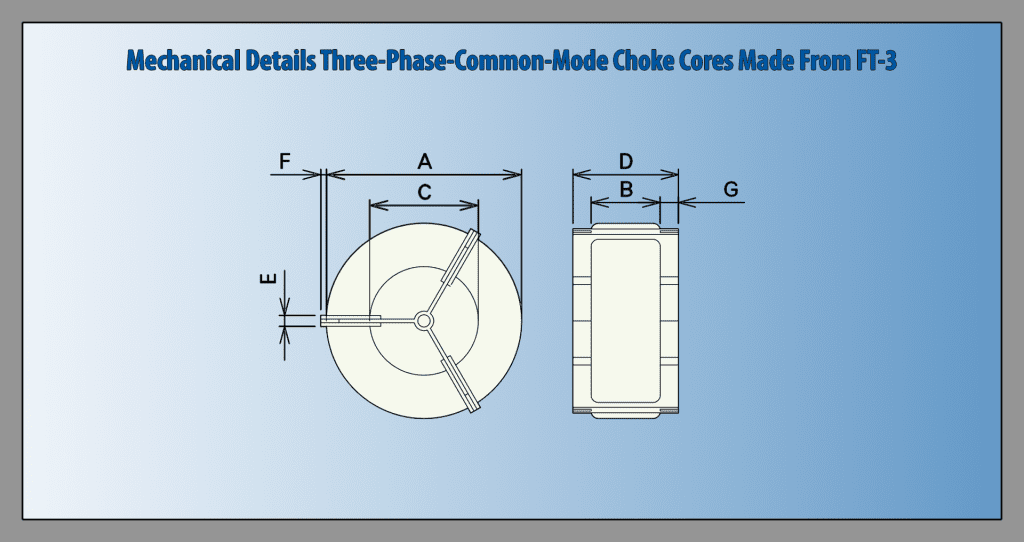

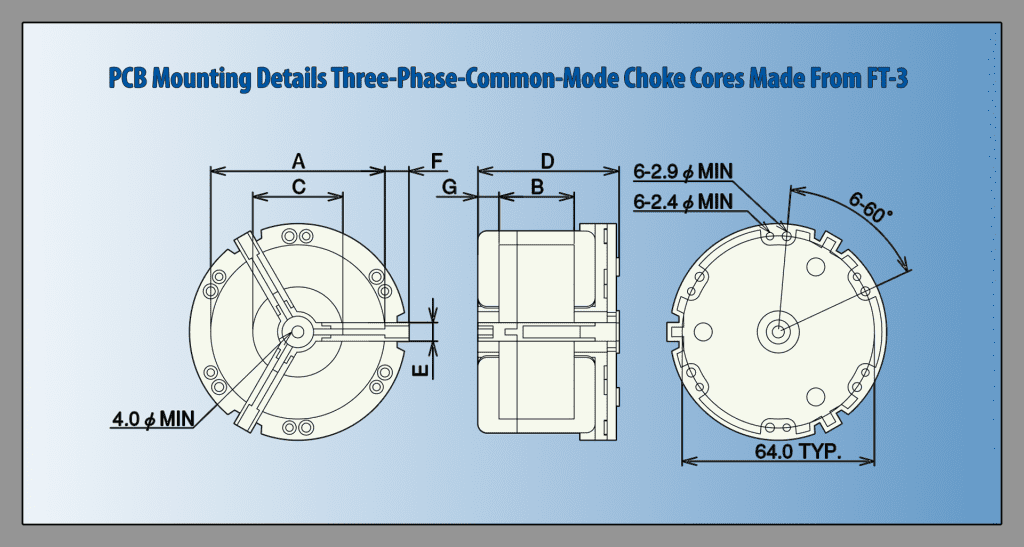

THREE-PHASE CORES

For the designer interested in winding common mode choke coils for a specific application, we have available the following standard cores for three-phase phase common-mode chokes.

These are toroidal-shaped tape-wound cores made from nanocrystalline amorphous metal.These cores are inserted into a protective plastic case made from a UL94 V-0 certified resin (130℃: PBT, 155℃: PET heat resistance). The case has built-in winding separators to add in creepage and dialectic isolation requirements. The below table lists: Product code and part number for cores made with FT-3KM material.

FT-3KM N SERIES - NANOCRYSTALLINE "M TYPE" TOROIDAL CORES – THREE-PHASE CASE

| Product Code | P/N | Finished Dimensions (mm) | Ac (mm2) TYP | Lm (mm) TYP | Wt (g) TYP | AL value (µH/n2) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A ±0.7 | B ±0.7 | C ±0.5 | D ±0.7 | E REF | F REF | G REF | 10 kHz MIN | 100 kHz ±30% | |||||

| F1AH0702 | FT-3KM N2515D | 27.6 | 16.0 | 12.6 | 22.0 | 3.2 | 1.0 | 3.0 | 46.9 | 62.8 | 28 | 41.6 | 15.3 |

| F1AH0703 | FT-3KM N3320E | 35.6 | 17.4 | 19.0 | 27.0 | 3.2 | 1.5 | 4.0 | 73.1 | 73.3 | 56 | 49.7 | 19.9 |

| F1AH0704 | FT-3KM N4225E | 46.0 | 19.0 | 21.0 | 27.0 | 4.0 | 3.0 | 4.0 | 95.6 | 105.2 | 95 | 51.4 | 20.6 |

| F1AH0705 | FT-3KM N5034E | 54.0 | 19.0 | 30.0 | 29.0 | 4.0 | - | 5.0 | 90.0 | 131.9 | 110 | 38.6 | 15.4 |

| F1AH0706 | FT-3KM N6442E | 68.0 | 19.0 | 38.0 | 29.0 | 5.0 | - | 5.0 | 123.8 | 166.5 | 184 | 42.0 | 16.8 |

| F1AH0708 | FT-3KM N5434G | 58.0 | 25.0 | 30.0 | 47.0 | 6.2 | 8.0 | 7.0 | 150 | 138.0 | 210 | 64.1 | 24.5 |

Download EMC brochure for information on common mode components:

WOUND COMMON CHOKES USING NANOCRYSTALLINE MATERIAL

Standard wound common mode choke coils and common-mode chokes are available as standard products for DC and single-phase AC power lines (rated current from 5A to 40A) and for three-phase AC power lines (rated current from 3A to 600A).

Three-phase wound components

Custom common mode chokes are available upon request, for your application you can pick the standard product that most closely meets your needs, or fill out our request form for a recommendation.

Typical applications include various portions of the power supply/inverter such as input single and three-phase noise filters, active harmonic filters, output noise filters, DC Power Lines, or Signal Lines.LARGE THREE-PHASE WOUND COMPONENTS

Download EMC brochure for information on common mode components:

Nanocrystalline Amorphous Metal

Nanocrystalline amorphous metal is produced by rapidly quenching a molten alloy to produce an amorphous metal (similar to Metglas®) and then heat treating this alloy at a higher than its crystallization temperature. Heat treating the amorphous ribbon in this matter creates Nanocrystalline grains that are approximately 10nm in size.

Annealing changes BH loops We produce three types of Nanocrystalline material:- M-type material is Nanocrystalline material with no magnetic field applied during annealing.

- H-type material is formed by annealing with a magnetic field applied parallel to the ribbon’s surface, creating a squarer BH loop.

- L-type material is formed by annealing with a magnetic field applied perpendicular ribbon’s surface, creating a flatter BH loop.

- High saturation magnetic flux density, more than 1 Tesla

- High permeability over 10,000u at 100kHz

- Excellent temperature characteristics. Very high Curie temperature (570°C) resulting in small permeability variation (less than +/-10%) at a temperature range of -40°C to 150°C.

How amorphous ribbon is made

The casting process - Amorphous ribbon (similar to Metglas®), is cast in widths up to 8 inches wide and then is slit to the width required for winding. Special winding machines wind the ribbon into various Toroidal, Oval, and C-core shapes. Cores then are further processed via cutting, coating, and annealing according to standard offerings and customer requests.