ABOUT SURGE ABSORBER CORES

These toroidal cores are made from a Nanocrystalline ribbon which is processed using an exclusive anneal, which is done under a magnetic field to tailor the BH curve for these specific applications. Both absorbing beads (leaded and non-leaded) and Surge Absorber Cores have a saturation magnetic flux density of Bs=1.23T, which is twice as high as a Co-based amorphous metal, and nanocrystalline core vs ferrite core is three times higher than that of a Ni-Zn ferrite. The core loss is 80W/kg at 100kHz, Bm=0.2T, which is comparable to a Co-based amorphous metal along with the pulse permeability.

Nanocrystalline core vs ferrite core have very stable performance concerning temperature, due to their high Curie temperature of 570°C. Note that the Co-based amorphous metal and Ni-Zn ferrite Curie temperature is approximately 200°C. Nanocrystalline toroidal cores have a very small decrease in permeability and increase in coercivity and core loss over time (aging effect), as opposed to Co-based amorphous metals which have rather large changes in these values over time. Nanocrystalline amorphous metal offers size and labor savings for various power conversion and EMC applications such as power line filters and diode surge suppressors.SURGE ABSORBER BEADS

These toroidal cores are used for low-power power line filters and diode surge suppressors are made from NANO amorphous tape. They perform well when used to suppress various kinds of current or voltage surges in Switched-Mode Power Supplies(SMPS), Frequency Inverters, ASD and UPS, and other applications for effective noise suppression caused by rapid changes in current.

The high pulse permeability of these cores allows for excellent performance in the suppression of reverse recovery current from the diode (diode surge suppressor), and ringing or surge current from the switching circuit.The saturation magnetic flux density is twice as high as that of the Co-based amorphous metal, and the nanocrystalline core vs ferrite core is three times higher than that of the Ni-Zn ferrite. The pulse permeability and the core loss are comparable to a Co-based amorphous metal. As a result, a core made of this material offers higher performance in the suppression of surge current and voltage.

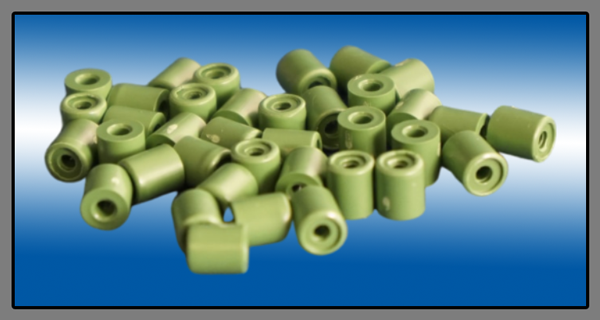

Absorbing beads have an inner diameter of 1.6mm and an outer diameter of 4 to 5mm, and lengths range from 5 to 7mm. These suppress various kinds of surge currents, acting as a diode surge suppressor from the dv/dr of a switching diode.These have exceptional performance in applications such as:

1. Suppression of reverse recovery current and surge current from a diode in switching mode power supplies or inverters. 2. Suppression of surge current at the moment of activation of a switching diode, such as power MOS-FET (diode surge suppressor). 3. Suppression of spike or ringing current generated in a switching circuit. 4. A power line filter.

Toroidal core Surge Absorber beads

LEADED SURGE ABSORBER BEADS

Leaded Beads have the same properties as the Non-Leaded Absorber Beads above but allow for direct PCB mounting and come in both horizontal and vertical versions.

Horizontal and vertically mounted leaded cores

Cross Reference To Other Common Beads

| AMOBEADS® vs. FM BEADS® | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| AMOBEADS® | OD (mm) | ID (mm) | HT (mm) | Total Flux (u Wb) min | Al Value (u H/N2) min | FM BEADS® | OD (mm) | ID (mm) | HT (mm) | Total Flux (u Wb) min | Al Value (u H/N2) min |

| AB3X2X3W | 4 | 1.5 | 4.5 | 0.9 | 3 | FT-3AM B3X | 4 | 1.5 | 5 | 2.2 | 2 |

| AB3X2X4.5W | 4 | 1.5 | 6.0 | 1.3 | 5 | ||||||

| AB3X2X6W | 4 | 1.5 | 7.5 | 1.8 | 7 | FT-3AM B3AR | 4 | 1.5 | 7 | 3.6 | 3.3 |

| AB4X2X4.5W | 5 | 1.5 | 6.0 | 2.7 | 9 | ||||||

| AB4X2X6W | 5 | 1.5 | 7.5 | 3.6 | 12 | FT-3AM B4AR | 5 | 1.5 | 7 | 7.3 | 5.5 |

| AB4X2X8W | 5 | 1.5 | 9.5 | 4.8 | 16 | ||||||

| AMOBEADS® with lead vs. FM BEAD® with lead | |||||||||||

| AMOBEADS® | OD (mm) | LENGTH for Leads (mm) | HT for Core (mm) | Total Flux (u Wb) min | Al Value (u H/N2) min | FM BEADS® | OD (mm) | LENGTH for Leads (mm) | HT for Core (mm) | Total Flux (u Wb) min | Al Value (u H/N2) min |

| LB4X2X8F | 6 | 16 | 12 | 4.8 | 16 | FT-3AM B4ARL | 5 | 15 | 7 | 7.3 | 5.5 |

| LB4X2X8U | 6 | 20 | 12 | 4.8 | 16 | FT-3AM B4ARL | 5 | 13 | 7 | 7.3 | 5.5 |

| Spikekiller® vs. Surge Absorber® (Total Flux equivalent products) | |||||||||||

| Spikekiller® | OD (mm) | ID (mm) | HT (mm) | Total Flux (u Wb) min | Al Value (µ H/N2) min | Surge Absorber® | OD (mm) | ID (mm) | HT (mm) | Total Flux (u Wb) min | Al Value (u H/N2) min |

| SA7X6X4.5 | 9.0 | 4.4 | 7.5 | 1.8 | 1.1 | ||||||

| SA8X6X4.5 | 10.0 | 4.4 | 7.5 | 3.6 | 2.0 | ||||||

| SA10X6X4.5 | 12.3 | 4.4 | 7.5 | 7.2 | 3.3 | FT-3AH C13X | 14.9 | 7.5 | 5.5 | 7.6 | - |

| SA14X8X4.5 | 16.3 | 6.3 | 7.5 | 10.8 | 3.6 | FT-3AH C11A | 14.7 | 8.6 | 6.4 | 11.8 | - |

Download EMC brochure for information on beads

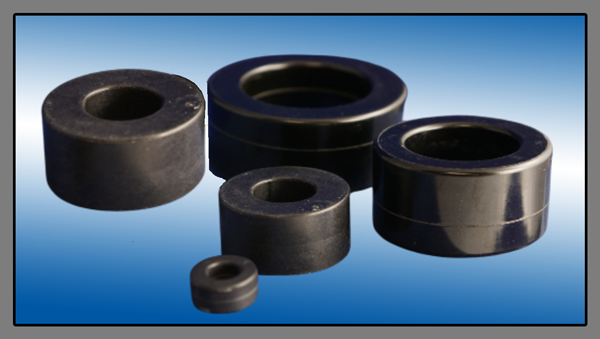

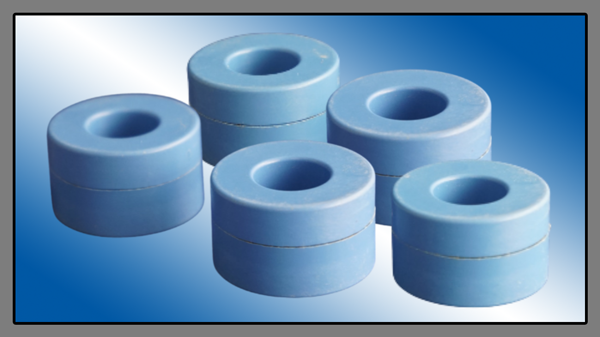

SURGE ABSORBER CORES

Saturable Cores are surge absorbers used in medium to large handling power applications. These blue line absorber toroid cores and black inductive absorber cores use a Nanocrystalline material with a special anneal, providing a high saturation flux density of Bs=1.23T and low core loss of 80W/kg at 100kHz, Bm=0.2T.

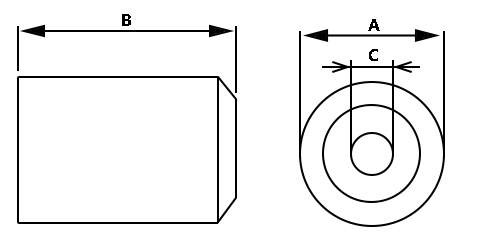

Surge Absorber Toroidal Cores are normally used as a single-turn choke as a line absorber or inductive absorber. Saturable cores are also appropriate for MagAmp circuits when used below 150kHz .| Finished dimensions (±0.3mm) | 2Φs (µWb) min | |||||||

|---|---|---|---|---|---|---|---|---|

| OD (mm) | ID (mm) | HT (mm) | Ac (cm2) | Lm (cm) | Mass (g) | 25°C | 120°C | |

| MP1005LF3S | 10.9 | 5.6 | 5.7 | 0.060 | 2.59 | 1.2 | 11.8 | 11.1 |

| MP1205LF3S | 13.8 | 6.8 | 6.6 | 0.057 | 3.14 | 1.4 | 11.2 | 10.6 |

| MP1303LF3S | 14.7 | 7.9 | 5.1 | 0.041 | 3.50 | 1.1 | 8.1 | 7.6 |

| MP1305LF3S | 14.4 | 7.9 | 6.7 | 0.057 | 3.46 | 1.5 | 11.2 | 10.6 |

| MP1405LF3S | 15.8 | 7.9 | 6.7 | 0.083 | 3.67 | 2.3 | 16.3 | 15.3 |

| MP1506VF3S | 17.1 | 7.8 | 8.3 | 0.140 | 3.86 | 4.1 | 27.6 | 25.9 |

| MP1603VF3S | 17.8 | 11.0 | 5.1 | 0.041 | 4.50 | 1.4 | 8.1 | 7.6 |

| MP1805VF3S | 20.8 | 10.8 | 6.8 | 0.108 | 4.88 | 4.0 | 21.3 | 20.1 |

| MP1903VF3S | 21.2 | 11.0 | 5.1 | 0.082 | 5.00 | 3.1 | 16.1 | 15.2 |

| MP1906VF3S | 21.2 | 11.0 | 8.3 | 0.161 | 4.99 | 6.1 | 31.7 | 29.9 |

| MP2303VF3S | 24.9 | 14.9 | 5.1 | 0.081 | 6.19 | 3.8 | 15.9 | 15.0 |

| MP2705LF3S | 29.5 | 14.8 | 6.7 | 0.207 | 6.89 | 10.8 | 40.7 | 38.3 |

| MP3210VF3S | 35 | 19.9 | 11.5 | 0.388 | 8.58 | 25.3 | 76.4 | 71.9 |

| Total Flux equivalent products Mean magnetic path equivalent products | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| MS series | OD (mm) | ID (mm) | HT (mm) | Total Flux (µ Wb) min | Le (mm) | Surge Absorber® | OD (mm) | ID (mm) | HT (mm) | Total Flux (µ Wb) min | Le (mm) |

| MS7X4X3W | 9.1 | 3.3 | 4.8 | 3.2 | 18.8 | ||||||

| 9.1 | 3.3 | 4.8 | 3.2 | 18.8 | FT-3AH T8A | 9.5 | 4 | 6.6 | 11.8 | 20.4 | |

| MS10X7X4.5W | 11.5 | 5.8 | 6.6 | 4.7 | 26.7 | ||||||

| 11.5 | 5.8 | 6.6 | 4.7 | 26.7 | FT-3AH C10A | 11.4 | 4.8 | 6.4 | 15.7 | 25.1 | |

| MS11X9W | 13.8 | 6.8 | 6.6 | 3.2 | 30.5 | ||||||

| 13.8 | 6.8 | 6.6 | 3.2 | 30.5 | FT-3AH T12A | 13.5 | 6.6 | 6.6 | 15.7 | 31.4 | |

| MS12X8X4.5W | 13.8 | 6.8 | 6.6 | 6.3 | 31.4 | FT-3AH C13X | 14.9 | 7.5 | 5.5 | 7.6 | 34.9 |

| 13.8 | 6.8 | 6.6 | 6.3 | 31.4 | FT-3AH T12A | 13.5 | 6.6 | 6.6 | 15.7 | 31.4 | |

| MS15X10X4.5W | 16.8 | 8.8 | 6.6 | 7.9 | 39.3 | FT-3AH C16X | 18.2 | 10.6 | 5.5 | 7.8 | 45.0 |

| 16.8 | 8.8 | 6.6 | 7.9 | 39.3 | FT-3AH T15A | 16.7 | 8.3 | 6.6 | 19.7 | 39.3 | |

| MS16x10X6W | 17.8 | 8.8 | 8.1 | 12.6 | 40.8 | FT-3AH C11A | 14.7 | 8.6 | 6.4 | 11.8 | 36.1 |

| 17.8 | 8.8 | 8.1 | 12.6 | 40.8 | FT-3AH T15A | 16.7 | 8.3 | 6.6 | 19.7 | 39.3 | |

| MS18X12X4.5W | 19.8 | 10.8 | 6.6 | 9.5 | 47.1 | FT-3AH T8A | 9.5 | 4.0 | 6.6 | 11.8 | 20.4 |

| 19.8 | 10.8 | 6.6 | 9.5 | 47.1 | FT-3AH T18A | 19.7 | 6.6 | 10.3 | 23.6 | 47.1 | |

| MS21X14X4.5W | 22.8 | 12.8 | 6.6 | 11.0 | 55 | FT-3AH C11A | 14.7 | 8.6 | 6.4 | 11.8 | 36.1 |

| 22.8 | 12.8 | 6.6 | 11.0 | 55 | FT-3AH C12A | 21.3 | 12.7 | 7.5 | 15.7 | 53.4 | |

| MS12X8X3W | 13.7 | 6.4 | 4.8 | 4.2 | 31.4 | ||||||

| 13.7 | 6.4 | 4.8 | 4.2 | 31.4 | FT-3AH T12A | 13.5 | 6.6 | 6.6 | 15.7 | 31.4 | |

| MS15X10X3W | 16.7 | 8.4 | 4.8 | 5.3 | 39.3 | ||||||

| 16.7 | 8.4 | 4.8 | 5.3 | 39.3 | FT-3AH T15A | 16.7 | 8.3 | 6.6 | 19.7 | 39.3 | |

| old-MA26164.5 | 26 | 16 | 4.5 | 18 | 66 | FT-3AH C54A | 26.5 | 11.6 | 8.5 | 16 | 58.9 |

How amorphous ribbon is made

The casting process

The ribbon is cast in widths up to 8 inches wide and then is slit to the width required for winding. Special winding machines wind the ribbon into various Toroidal, Oval, and C-core shapes. Cores then are further processed via cutting, coating, and annealing according to standard offerings and customer requests.Nanocrystalline Amorphous Metal

- M-type material is a Nanocrystalline material with no magnetic field applied during annealing.

- H-type material is formed by annealing with a magnetic field applied parallel to the ribbon’s surface, creating a squarer BH loop.

- L-type material is formed by annealing with a magnetic field applied perpendicular ribbon’s surface, creating a flatter BH loop.