ABOUT HIGH FREQUENCY MAGNETIC COMPONENTS

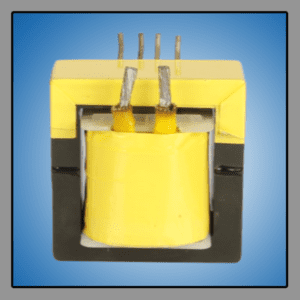

High frequency magnetic components such as transformers and inductors operate with the same fundamental principles as 50/60Hz transformers and inductors. High frequency electrical power conversion applications such as SMPS (switch mode power supplies) use frequencies from 20kHz to over 1MHz.

In its simplest form, a coil is wound around a magnetic core creating a magnetic field. However, operating at a higher frequency these High Frequency Magnetic Components provide benefits, such as a smaller size for a given power rating. In general, the higher the operating frequency, the smaller the inductor/ high frequency power transformer.

Having a smaller HF transformer/inductor reduces the mean length per turn resulting in less copper wire needed, thus reducing the I2R losses of the windings, making the transformer/inductor more efficient.

A wide variety of geometries are available for high frequency magnetic components such as:

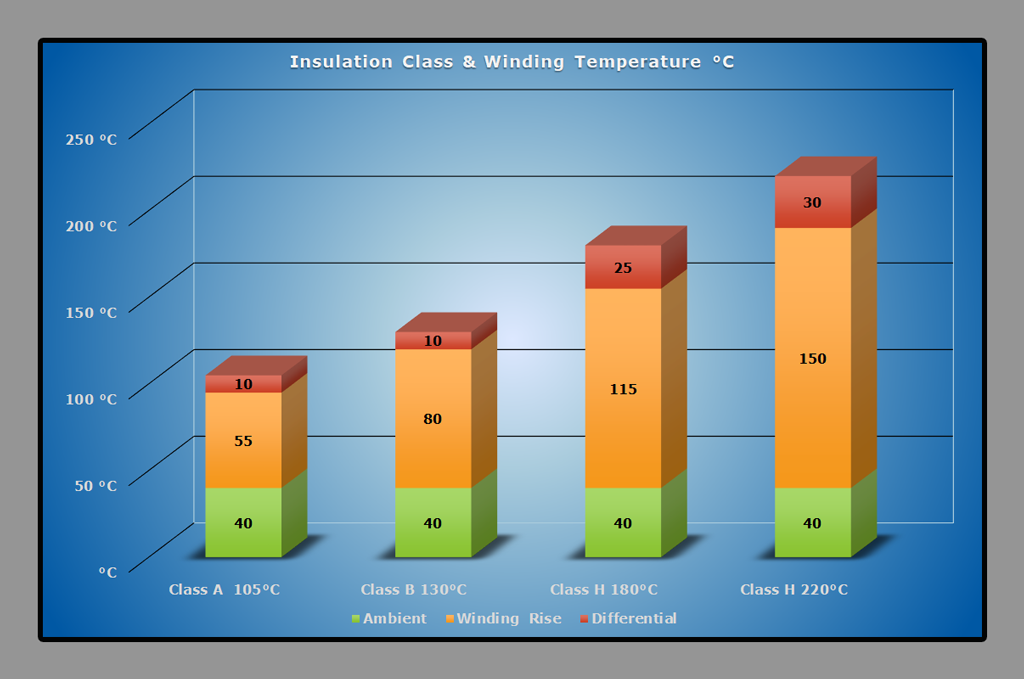

The insulation class takes into account the temperature rise of the windings and insulation above the existing ambient temperature. These classes describe the insulating materials' operating temperature ratings. Letter classifications are used for different designations of system temperatures in degrees Celsius. The system temperature is the maximum temperature at the hottest spot in the winding. Standard features of our high frequency magnetic components include insulation voltages up to 6kV, double insulated materials, and class F (155°C) or class H (180°C) insulation.

Design parameters needed for a high frequency power transformer:

Design parameters needed for a high frequency power transformer:

- EE ferrite cores: ee16 core, ee19 core, ee25 core, ee35 core, ee42 core, and ee55 core.

- EI ferrite cores: EI12.5, EI16, EI19, EI2, EI22, EI25, EI28, EI30, EI33, EI35, EI40, EI50 and EI60.

- EER ferrite cores: EER25.5, EER28, EER28L, EER35, EER40, EER42, and EER49.

- ETD ferrite cores: ETD19, ETD24, ETD29, ETD34, ETD39, ETD44 and ETD49.

- Toroidal ferrites, MPP, iron powder, amorphous, and Sendust.

- Pot core ferrite - pot core inductors and pot core transformers.

- Ferrite drum core.

- Ferrite rods.

| Insulation / Thermal Class | Max temperature (°C) | Reference max ambient temperature (°C) | Max temperature rise (°C) |

|---|---|---|---|

| A | 100 | 40 | 75 |

| E | 115 | 90 | |

| B | 120 | 95 | |

| F | 140 | 115 | |

| H | 165 | 140 | |

| C | >165 | >140 |

Design parameters needed for a high frequency power transformer:

Design parameters needed for a high frequency power transformer:

- Choose a core.

- Based on the cores’ flux density, calculate the number of primary turns needed.

- Using the ratio of primary to secondary voltage, calculate the number of secondary turns.

N = Primary turns

F = Frequency in Hz

B = Flux density in Gauss

Ae = Cross sectional area of the core (cm2)

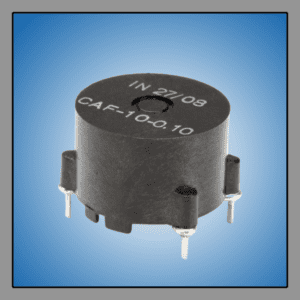

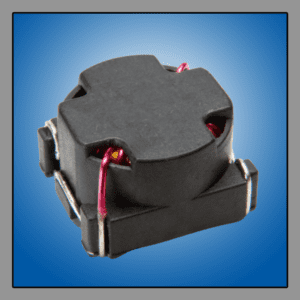

COMMON MODE CHOKES

A common mode choke serves as an efficient way to filter in-phase supply lines and enable equipment to meet strict electrical radiation specifications. It helps filter and block high-frequency, common mode current noise in the supply lines. High frequency noise can potentially damage other electrical components or devices in your system if left unfiltered.

CA Series – Common Mode ChokesFeatures

CA Series Common Mode Toroidal Chokes – Datasheet.

- Made with custom mounting (TH or SMD)

- Designed to meet specific inductance requirements

- Engineered for higher current ratings

- Manufactured in an ISO 9001 certified facility

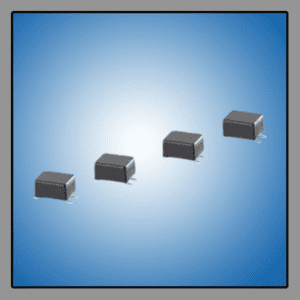

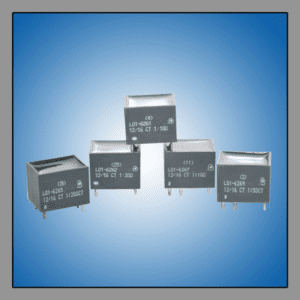

CLJ-2 Series – Miniature SMD Common Mode Double ChokesThis common mode choke line is designed for SMD (surface mount) applications and is packaged for pick and place compatibility. Our team has more than 20 years of manufacturing experience so your SMD products provide consistent and reliable coplanarity.

We offer many standard options as a direct drop-in solution. Other inductance values, higher current ratings and special high-temp designs (150°C ambient temperatures) are available upon request.

Features

CLJ-2 Series Miniature SMD Common Mode Double Chokes – Datasheet.

- Surface mount design (can convert to TH upon request)

- High attenuation over a broad frequency range up to 500 MHz

- Available as a sector (suffix S) winding or bifilar winding design

- (Sector: provides less capacitance between windings)

- (Bifilar: provides better coupling between windings, less leakage)

- Fully RoHS compliant

- Meet lead-free reflow level J-STD-020C

- Manufactured in an ISO 9001 certified facility

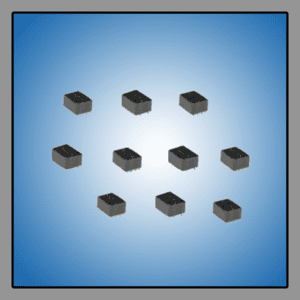

CMJ Series – SMD Miniature Common Mode ChokesThe CMJ common mode choke series is also designed for SMD (surface mount) applications and pick and place compatibility. As with our CLJ-2 Series, our CMJ series provides excellent coplanarity, which means you don’t have to worry about mounting issues.

Features

CMJ Series SMD Miniature Common Mode Chokes – Datasheet.

- Miniature, low-cost solution

- High attenuation over a wide frequency range

- Manufactured in an ISO 9001 certified facility

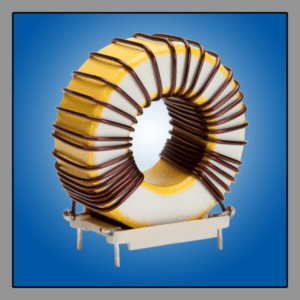

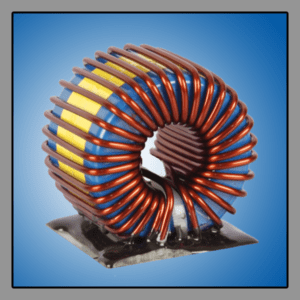

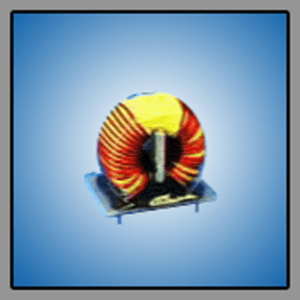

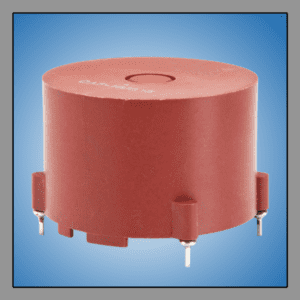

TOROIDAL INDUCTORS AND TOROIDAL CHOKES

We provide an extensive range of high frequency toroidal inductors and toroidal chokes. Our standard lines offer a broad range of sizes, inductance, current ratings, and designs are available for surface mount and through-hole applications.

Applications include SMPS filters, DC/DC converters, energy storage devices, and differential mode and common mode filtering.

DP Series

The DP Series is an efficient, economical alternative to conventional chokes or inductors. Used in energy storage and EMI filtering, these low-radiation inductors effectively control AC output ripple in power supplies. They’re available in a wide range of current ratings and inductance values.

Features

DP Series Toroidal Power Inductors - Datasheet

- Include hot-solder leads for simple PC board mounting

- Operating frequency of up to 100kHz

- Built-in ISO 9001 and TS-16949 certified facility

- RoHS compliant

SH SERIES - TOROIDAL INDUCTORS - NATIONAL SEMICONDUCTORS SIMPLE SWITCHER ™

Our SH toroidal Inductor lines are designed to be used with National Semiconductors Simple Switcher, at switching frequencies of 50kHz, 150kHz, and 260kHz.

These series offer high energy storage capabilities, with minimal saturation risks and they provide great stability between no-load operations and full-load. They’re designed for continuous operation and are manufactured in ISO 9001 certified facilities.

SH260 Toroidal Inductor Series

These toroidal inductors are an economical option to use with the National Semiconductors Simple Switcher ™ 260kHz series.

Features

SH260 Series Inductors for National Semiconductors 260kHz Simple Switcher ™ - Datasheet

- Available in SMD and TH versions

- Compatible with part number LM267X-L45 through LM267X-L50 and LM267X-L41

- Meet reflow J-STD-020C standard

- RoHS compliant

SH150 Toroidal Inductor Series

These toroidal chokes are designed to use with the National Semiconductors Simple Switcher ™ 150 kHz series.

Features

SH150 Series Chokes for National Semiconductors 150kHz Simple Switcher ™ - Datasheet

- Available in both SMD and TH versions

- Operate in temperatures from -40°C to 125°C

- Compatible with part numbers LM259X-L1 to LM259X-L44 and LM258X-L

- Meet reflow J-STD-020C standard

- RoHS compliant

HIGH FREQUENCY MAGNETIC COMPONENTS - CURRENT TRANSFORMERS

Our high frequency current transformers provide a low-cost solution to measure high electrical currents without touching or breaking the circuit. These current transformers (current sensing devices) are used primarily for safety reasons, transforming the circuit’s line current into a proportionally reduced current that is easily measured.

Current sensors isolate your measuring instruments from potentially high currents in the circuit. Often in power applications, current sensors are used in protective relays and metering.

They’re ideal for isolating current feedback signals in switching power supplies, motor current load or overload detection, lighting applications, and sonar current applications.

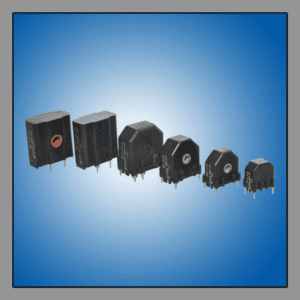

AS Current Sensor Series

AS Series is designed as a low-cost solution for any control system and most AC current monitoring/measuring applications. The current sensors can serve as the feedback elements from SMPS outputs and the pulse control module.

These AC current sensors are manufactured in an ISO 9001-certified facility, and they meet VDE standards.

Features

AS Series Current Sense Transformers - Datasheet

- Fully encapsulated for better protection

- Surface mount design (can convert to TH, upon request)

- RoHS compliant

- 2500Vac isolation between primary line and secondary winding

- Primary current rating up to 30amps

- Operating frequency range from 20kHz to 200kHz

POT CORE TRANSFORMERS - HIGH FREQUENCY MAGNETIC COMPONENTS

These ferrite core transformers/ferrite core inductors confine the magnetic field of the HF transformer windings to within the boundaries of the core.

It also protects the transformer windings from the effects of intruding magnetic fields from the outside of the core, providing extremely good EMI characteristics. Additional magnetic shields can be added around the outside of the pot core transformer, to provide improved field containment and protection from external interference.

This same concept applies to pot powder core inductors.

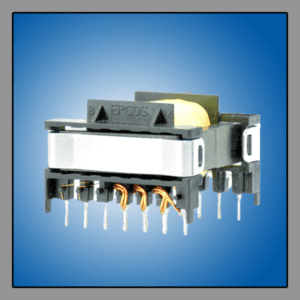

PULSE TRANSFORMERS

For high frequency applications, these are typically ferrite core transformers. These transformers allow the transmission of electrical pulses with fast rise and fall times at a comparatively constant amplitude. One key design goal of a Pulse transformer is to minimize distortion of the pulse shape. To achieve this minimal distortion, a low value of leakage inductance and distributed capacitance is needed along with a high open-circuit inductance. It is also important to design with a high insulation resistance because of the high voltage created from the pulse edges.

To provide low switching losses in power semiconductors, a good transient response is essential to maintain a rectangular pulse shape on the secondary. As in most power applications, it is important to protect the primary side of the circuit from high-powered transients created by the load, along with dielectric isolation between drive controller and power output circuits. This is accomplished by designing a pulse transformer with low coupling capacitance between the primary and secondary.

FERRITE ROD CORE/ FERRITE DRUM CORE INDUCTORS

This is a ferrite core inductor constructed with single or multi-layer windings on a ferrite drum core or ferrite rod core. Leads can be on the same or opposite ends of the core.

These are used in power and RF applications. They are made in many core materials including ferrite and powdered iron. Unlike air core inductor/air core choke the magnetic field is not contained in the core.

Both rod and bobbin shapes are supplied in tape and reel packaging for auto-placement.

AIR CORE INDUCTORS - HIGH FREQUENCY MAGNETIC COMPONENTS

An air core inductor/ air core choke does not use a magnetic core made of a ferromagnetic material. Coils are wound on a nonmagnetic material such as plastic or ceramic. They can also be self-supporting by using bondable magnet wire. This is done so that there is only air inside the windings.

It is important to firmly support the coil such that the mechanical vibration of the windings does not cause variations in the inductance.

Typical applications are for high frequencies and low inductance requirements where the core losses from ferromagnetic materials would be too high.