Lamp Irradiator Assemblies

Our proven LIAs (UV Lamp Irradiator Assemblies)are UV reflector assemblies that provide an instant solution to reliable cooling of UV lamps to create a UV curing system. The lamp housing (lamp head) provides mounting and a highly efficient method of focusing UV energy onto the curing surface. Many engineers find that the most time-consuming aspect of building a UV curing system is controlling UV bulb temperature and focusing UV energy on the curing surface. Incorrectly maintaining lamp temperature severely degrades the performance and life of any UV lamp.

Irradiator Construction

These UV irradiators consist of a heavy-duty housing supporting a linear extruded aluminum reflector heatsink and a UV reflector sheet insert, which acts as an enhanced reflectance liner. The UV reflector sheet is in intimate contact with the aluminum reflector finned extrusion allowing it to resist the heat-related yellowing that plagues other non-heatsink-based designs. In the event that the UV reflector sheet becomes damaged, it is easily replaced, minimizing downtime.

Our UV dryer reflectors are designed specifically for each ultraviolet lamp size. They maintain optimum arc lamp operation temperatures on the medium-pressure mercury vapor lamp envelope, end seals, and end fittings. The UV irradiator forms an air-cooling plenum, cooling the ultraviolet lamp end-fittings and not over-cooling the UV curing lamp envelope.

In addition to lamp cooling (these also work with a metal halide lamp) our Lamp Irradiator Assembly allows for cooling of the work surface and supporting the lamp above the substrate, reflecting UV energy in an efficient curing pattern.

The purpose of an irradiator assembly is to:

- Focus the lamp's UV energy optimally for fast curing.

- Support the lamp above the substrate.

- The lamp head maintains proper cooling of the lamp envelope, capillary, and end-fittings.

UV Irradiators (reflector assemblies)are used in conjunction with other UV components, such as magnetic ballast, or metal halide ballast and arc lamp, to form a complete UV curing system providing effective UV drying of your product. Replacement UV reflector liners or UV reflector sheets and lamps are also available.

Even Cooling

The heatsink-based UV irradiator system provides thermal mass to allow even lamp cooling. This mass prevents transient changes in heating/cooling from being immediately transmitted to the lamp and impedes localized imperfections in cooling from manifesting themselves into thermal gradients. Heat sink-based LIAs are inherently a more robust approach to uniform lamp cooling and result in longer UV lamp life. We also offer cost-effective heatsink-based highly UV reflective aluminum reflector extrusions in four standard sizes. These sizes include E-175, E-350, PO-50, and PO-70.

Efficient Cooling

Optimizing cooling efficiency in an LIA is achieved by using a heatsink-based aluminum reflector, where the material has high thermal conductivity and the design maximizes the effects of surface area and turbulence. Within reason, the more surface area the better the UV lamp cooling. Also important is turbulence, because of the skin effect in cooling. A thin layer of air surrounding a cooling surface acts as a thermal insulator impeding the effect of forced air cooling. This layer needs to be disrupted by turbulent airflow, which can be created by providing irregular fins and fin geometries. For those that want to design their own UV Irradiator for a very cost-effective UV curing system we offer highly UV reflective aluminum reflectors extrusions in four standard sizes, see our E-175, E-350, PO-50, and PO-70

Our LIA's offer :

- Longer UV-lamp life.

- More UV energy to the curing target improves your throughput.

- Two focus versions.

- Faster development time in implementing cooling for UV curing equipment.

- No design or tooling investment is required.

- Reduced parts count.

- An excellent option for a UV retrofit system.

- Improved quality and better UV cure result through consistent cooling.

- Flexible lengths for almost any UV system: can be used for lamp arc lengths from 4 to 100 inches.

- UV Irradiators also have applications in ultraviolet blood irradiation, sterilization, water sterilizers, and air sterilizer.

- Optional dichroic reflector quarts sheets.

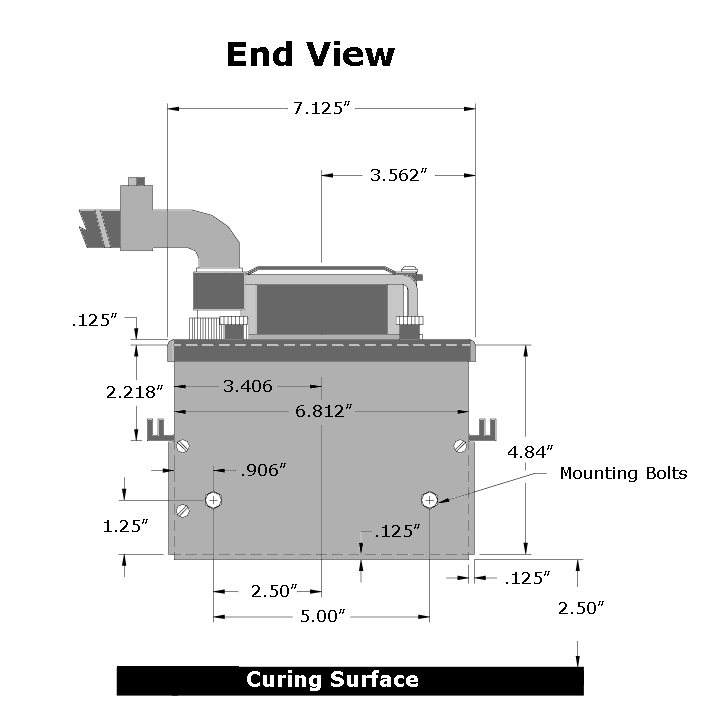

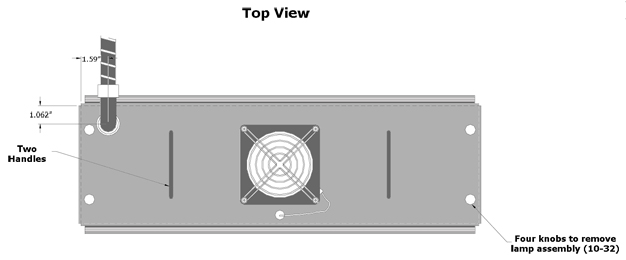

One of the most important features of our LIAs is the construction. This consists of a heavy-duty extruded housing that contains an extruded reflector profile (note these profiles are different than our stand-alone standard aluminum reflectors extrusions: E-175, E-350, PO-50, and PO-70 ). Inside this reflector profile is a high UV reflectance metal insert, which conforms to this profile. In addition to being rugged, the extruded UV reflector provides a large mass, which dissipates heat evenly. It allows uniform cooling across the entire UV lamp length. AC fans with appropriate wiring and lamp mounting provisions (lamp head) are also included.

Two focus versions are available:

The elliptical version projects a one-inch wide focus approximately 2.5” inches from the bottom of the LIA to the curing surface, optional dichroic reflector quarts sheets are available.

Non-focused (parabolic reflector) version projects an evenly diffused source of UV energy on the curing surface, approximately 4 to 5" wide, optional dichroic reflector quarts sheets are available.

How much longer is the LIA than the arc of the lamp?

Standard irradiators

| Part Number | Lamp Arc Length | Irradiator Length |

|---|---|---|

| HIR1004 | 4.00" | 14.06" |

| HIR1006 | 5.31" | 16.75" |

| HIR1008 | 8.00" | 18.93" |

| HIR10012 | 12.47" | 23.71" |

| HIR10018 | 18.47" | 29.28" |

| HIR10020 | 20.00" | 30.65 |

| HIR10025 | 25.47" | 36.28" |

| HIR10030 | 30.47" | 41.28" |

| HIR10032 | 32.00" | 43.09 |

| HIR10038 | 38.47" | 49.28" |

| HIR10042 | 42.00" | 52.81" |

| HIR10048 | 48.47" | 59.28" |

| HIR10050 | 50.00" | 60.81" |

| HIR10055 | 55.87" | 66.68" |

| HIR10060 | 60.47" | 71.28" |

| HIR10065 | 65.00" | 75.81" |

| HIR10072 | 72.00"" | 83.09 |

| HIR10077 | 77.46" | 88.28 |

* Above chart lists a few of our LIAs, note optional dichroic reflector quarts sheets come in 6" sections.