ABOUT NANOCRYSTALLINE CORES

Nanocrystalline metals start as a special Amorphous material, which is produced by using a rapid solidification technology where molten metal is cast into thin solid ribbons, by cooling at a rate of one million °C/second.

This Amorphous ribbon is then annealed under a magnetic field to create a nanocrystalline structure. This metal has high permeability, due to very low crystalline magnetic anisotropy.

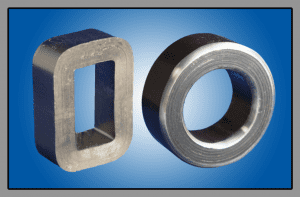

Nanocrystalline cores are made from a very thin Iron based amorphous ribbon, approximately 13 µm thick. Nanocrystalline ribbon is wound into toroidal and oval shapes. Our enhanced ribbon flatness results in more core cross-sectional area being occupied by the Nanocrystalline ribbon, allowing for ultra-low loss Nanocrystalline cores.

C-Cores and Block cores are impregnated with a special epoxy, which permits cutting ovals in half to form a set of cut C-Cores. For Block Cores, epoxy impregnation provides mechanical stability to the Nanocrystalline blocks. Cores intended for high efficiency transformers and common mode chokes are not impregnated since cutting of cores for these applications would significantly degrade material performance.

TECHNICAL ADVANTAGE

Where typical ferrite cores can only operate up to a flux saturation level (Bsat) of 0.49 Tesla, a Nanocrystalline metal core can operate at 1.23 to 1.32 Tesla. Combined with range of operating permeability of 5,000 to 31,000 µr at 100kHz and the flexibility of manufacturing large cores sizes, these cores can be an ideal solution for many magnetic components.Low Losses

Nanocrystalline magnetic cores have superior magnetic characteristics, such as the lowest core loss of any magnetic materials for transformers in the 10 to 100kHz range. This core loss is extremely stable over temperatures from -40°C to 140°C. This is because the Nanocrystalline structure responds to changes in magnetic fields (alternating AC fields) more readily than other materials, providing a BH loop that essentially exhibits no hysteresis losses. Magnetic field changes also induce currents, called eddy currents, which are an additional source of loss. These losses become significant at higher frequencies when using thicker laminations. The super thin nature (13 µm) of the Nanocrystalline ribbon limits these losses by reducing the circulation of these eddy currents.APPLICATIONS

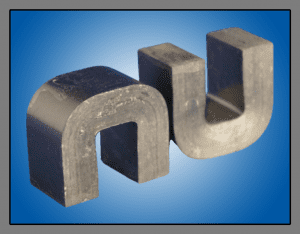

When used in higher frequency applications, Nanocrystalline cores are more efficient, smaller, and lighter, than cores made of silicon steel, ferrite, and powdered iron, by providing high saturation flux density and low magnetization losses. These properties make Nanocrystalline highly suitable for power transformers at frequencies ranging from 10 to 100kHz and common-mode chokes from 10kHz to 100 MHz.C-Cores

- High frequency transformer in Charging Inverters, Induction Heating, and Welders.

- Medium frequency transformer in high-frequency DC/DC converter

- Medium and high-power switching power supplies

Characteristics

- High saturation flux density - reduce core volume

- Rectangular form - easy coil assembly

- Air gaps can be used to reduce DC-bias-saturation

- Low core loss

- Good temperature stability of Saturation Induction and Permeability

UNCUT NANOCRYSTALLINE CORES FOR VERY LOW LOSS TRANSFORMERS

Medium-voltage, medium-frequency transformers (MFTs) used in high power density power electronics benefit from using designs based on specially processed uncut nanocrystalline cores. These Iron based low loss transformer cores made with a nanocrystalline alloy is composed of Fe, Si, B, Cu, Nb, etc.

The material is further processed, using a unique magnetic field anneal, to yield a nanocrystalline structure ideal for medium frequency transformers (MFTs). The saturation level of this material is relatively high, 1.23T, and the core loss is among the lowest of all materials in this frequency range.

Uncut field annealed nanocrystalline cores provide the ultimate low loss core for MFT applications. These cores are much smaller in size and weight, compared with those made with MnZn ferrite. This is because MnZn ferrite is limited to operating at a few kHz in high power density applications, due to the low saturation flux density. Uncut field annealed nanocrystalline cores have low core loss and a saturation flux density that is 4 times that of MnZn Ferrite, and a Bsat of 0.3T versus 1.2T. Even cut amorphous cores or cut nanocrystalline cores cannot match the performance of uncut field annealed nanocrystalline cores. For example, the uncut Oval (Square) cores have 1/5 of the core loss and the uncut Ring (Toroidal) cores have a 1/7 of the core loss of nanocrystalline cut cores.

MFTs are well suited for EV Chargers, Wireless Power, Welders, Smart Grids, and Traction converters, using a solid-state transformer (SST), which is operated at a much higher frequency than line frequency, and therefore the size and weight of the transformer can be significantly reduced. A key part of the SST using multistage power electronic converters, is the medium-frequency transformer.

Although cut cores are preferred for transformers due to the convenience of construction, they are lossy and acoustically noisy.

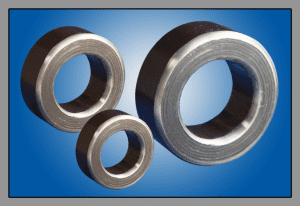

TOROIDAL-RING - NANOCRYSTALLINE CORES - FINEMET® Nanocrystalline material- FT-3TL

From a low loss and audible noise perspective, uncut field annealed nanocrystalline toroidal (ring) cores are the ideal choice. This is because the toroidal construction causes the magnetic flux to be constrained and homogeneously distributed throughout the core.

The toroidal core construction also provides for low magnetostrictive stresses, reducing audible noise and further reducing core losses.

The actual construction of the toroidal transformer windings and insulation may require special winding machines. Limitations of the winding shuttle to freely move in the ID of the core as windings and insulation layers are applied, need to be considered.

Higher voltages also mean that sufficient margins for creepage and clearance are maintained between the primary and secondary windings. In certain designs, limited space in the core ID may make the toroidal construction an unfavorable option.

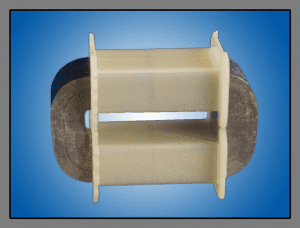

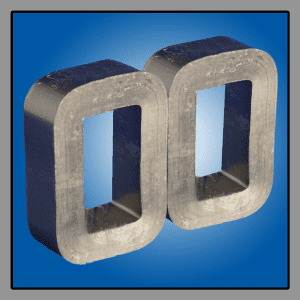

SQUARE-OVAL - NANOCRYSTALLINE CORES - FINEMET® Nanocrystalline material- FT-3TL

Field annealed uncut nanocrystalline cores with a Square (oval) shape offer an economical solution for MFT designs regarding high efficiency, high power density, and low acoustic noise emission.

The oval core is a good compromise for low losses, low acoustic noise, and high-power density. It also enables the use of more manufacturable winding techniques.

For example, windings can be applied to insulative bobbins providing the dielectric withstand, creepage, and clearance required between the primary and secondary windings.

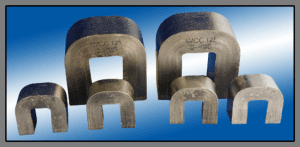

NANOCRYSTALLINE C-CORES SETS

These Nanocrystalline cores are wound in a C-Core configuration which is ideal for Medium frequency transformers. These C-Core sets can be stacked to increase the effective cross-sectional area to allow for larger transformer designs.

Nanocrystalline C-Cores allow for operation at higher frequencies at the same flux level, whereas traditional steel cores need to operate at increasingly lower flux densities as the frequency increases. In order to compensate for running at lower flux densities, significantly more material is needed.

Even with additional material, higher temperatures still occur. Another contributor to lowering losses is the I2R of the winding. A physically smaller Nanocrystalline core reduces the mean length per turn, hence the I2R copper losses and copper costs are lower. Further improvements can be realized by using uncut Nanocrystalline cores.

WINDING OPTIONS

For higher current applications, these cores open up new options for the conductor winding process that is not easily achievable for toroidally constructed cores:- Copper foil

- Large gauge square conductors

- Edge or disc winding

In each of the above options, the winding can be accomplished on a separate mandrel and assembled onto the C-Core after the winding process. Litz wire (a special type of multistrand wire) is commonly used for high current/high frequency designs. However, terminating litz wire for these applications can be expensive. An alternative to consider is disc or edge winding. This involves winding a rectangular wire that has a relatively high aspect ratio on its edge. The quasi-planar structure of this thin rectangular wire reduces the skin effect, but not as much as when using litz wire. Although copper or aluminum foil can also reduce skin effect properties, other parasitic winding effects need to be considered when using this winding method. Other advantages of using Nanocrystalline cores are: lower copper loss, reduced DCR, smaller size, and improved heat dissipation.

Low loss switching devices such as SiC MOSFETs that allow for operating frequencies of 100kHz, are now becoming cost effective for the high-power electronics designs. In the past, traditional EI and UI laminated inductors using 3% Ni and silicon grain-oriented steel could be used with little problem. Three percent nickel and silicon grain-oriented steel designs become physically large above 1kHz. These traditional laminate materials need to operate at a very low flux density at these frequencies, resulting in higher temperatures and much larger core sizes, than with a comparable Nanocrystalline core design. These are summarized in the below chart:

Amorphous & Nanocrystalline cores used in high frequency inductors versus competitive materials

This design assumes 50% permeability with 50 Oe of bias, 2500 perm ferrite was used for comparison and core determined at 20 kHz and 2 kg BAC

| Parameters | Nanocrystalline C-Core | Amorphous C-Core | Iron Powder | 6% Si Steel | 3% Si Steel | Ferrite |

|---|---|---|---|---|---|---|

| Bsat(T) | 1.23 | 1.56 | 1.0 to 1.4 | 1.2 | 1.85 | 0.35 |

| Permeability | 6,000 | 3,000 | 2 to 75 | 4,100 | 1,000 | 2,500 |

| Power Loss (W/Kg) | 10 | 35 | 550 | 185 | 275 | 65 |

| Turns | 1 | 2 | 8 | 2 | 4 | 5 |

When comparing Iron Powder to Amorphous core. The Amorphous core will tend to be less expensive, and have lower losses, smaller physical size, better heat dissipation, and are mechanically rugged. The Nanocrystalline core will have the lowest power loss and smaller size. However, cost of the Nanocrystalline core will be slightly higher.

Standard C-Cores Sets - FINEMET® Nanocrystalline material- F3

Design Data:

Technical Charts

- Saturation Induction vs. Temperature

- Permeability vs. Temperature

- C-Core - Mounting Methods - Brackets

- C-Core - Bobbins

Magnetization Curves

For high frequency power supplies with rating of tens of kilowatts to hundreds of kilowatts these nanocrystalline C-Cores offer higher saturation induction of 1.23 Tesla and lower losses allowing for compact and efficient transformer and inductor designs offering:- higher efficiency

- lower transformer weight

- reduced transformer volume

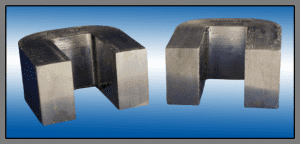

NANOCRYSTALLINE BLOCK CORES

Rectangular shapes of nanocrystalline metal block cores are produced by precisely stacking layers of nanocrystalline metal ribbon. This stacked ribbon assembly is then placed in a mold and impregnated with an epoxy rated for a continuous operating temperature of 155°C. Once the epoxy is cured, a robust block of nanocrystalline material is ready to be made into a wide variety of mechanical/magnetic configurations.

These nanocrystalline metal block cores offer a unique combination of high saturation induction (1.23 T), high permeability, and low core loss, and can be configured into various shapes, allowing for one large gap to be distributed across several smaller gaps, reducing fringing flux, and core loss.

Possible configurations:

Hybrids can be designed using C-Core sections with corresponding bricks for unique shapes.

Applications: Medium Frequency and High Power Inverters

Specifications for Nanocrystalline Block Cores

How amorphous ribbon is made

The casting process

Ribbon is cast in widths up to 8 inches in wide and then is slit to width required for winding. Special winding machines wind the ribbon in to various Toroidal, Oval and C-core shapes. Cores then are further process via cutting, coating, annealing according to standard offering and customer requests.

The casting process

Ribbon is cast in widths up to 8 inches in wide and then is slit to width required for winding. Special winding machines wind the ribbon in to various Toroidal, Oval and C-core shapes. Cores then are further process via cutting, coating, annealing according to standard offering and customer requests.

Nanocrystalline Amorphous Metal

Nanocrystalline amorphous metal is produced by rapidly quenching a molten alloy to produce an amorphous metal, and then heat treating this alloy at higher than its crystallization temperature. Heat treating the amorphous ribbon in this matter creates Nanocrystalline grains which are approximately 10nm in size.

Annealing alters the BH loopWe produce three types of Nanocrystalline material:

- M-type material is Nanocrystalline material with no magnetic field applied during annealing.

- H-type material is formed by annealing with a magnetic field applied parallel to the ribbon’s surface, creating a squarer BH loop.

- L-type material is formed by annealing with a magnetic field applied perpendicular ribbon’s surface, creating a flatter BH loop.

- High saturation magnetic flux density, more than 1 Tesla

- High permeability over 10,000u at 100kHz

- Excellent temperature characteristics. Very high Curie temperature (570°C) resulting in small permeability variation (less than +/-10%) at a temperature range of -40°C to 150°C.