- Low Voltage CTs

- Low Voltage VTs

- Metering CTs

- Three Phase CTs

- Relay Class Protection Current Transformers

- IEEE C57.13 and IEC Class CTs

- Split Core CTs

- Large Frame CTs

- Rectangle CTs

- Auxiliary/Summation CTs

- Medium Voltage Instrument Transformers

- Switchgear Style CTs

- Medium Voltage CTs

- Medium Voltage VTs -Three Phase

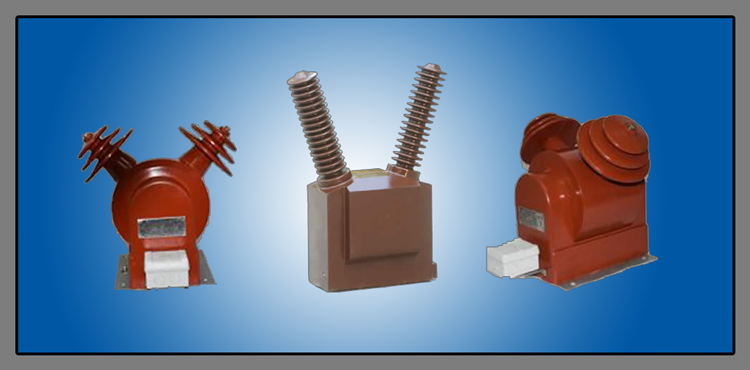

- Medium Voltage VTs -Single Phase

- Medium Voltage CPTs

- Bushing CTs

- Generator Style CTs

- Miniature and PC Mount 50 to 400Hz CTs

- Rogowski Coils & Sensors

- Oil Insulated CTs & VTs

ABOUT INSTRUMENT TRANSFORMERS

Instrument transformers comprise a large category of current and potential transformers for various voltage, frequency, and physical size ranges. We have broken them up into several different groupings: low voltage, which are system voltages under 15kV; high frequency, operating frequency over 1kHz; and size ranges from board mount parts up to current transformers with window sizes of 254mm by 610mm. Read through the different types we supply below and use our Instrument Transformer RFQ Form to request a specific part to meet your requirements.

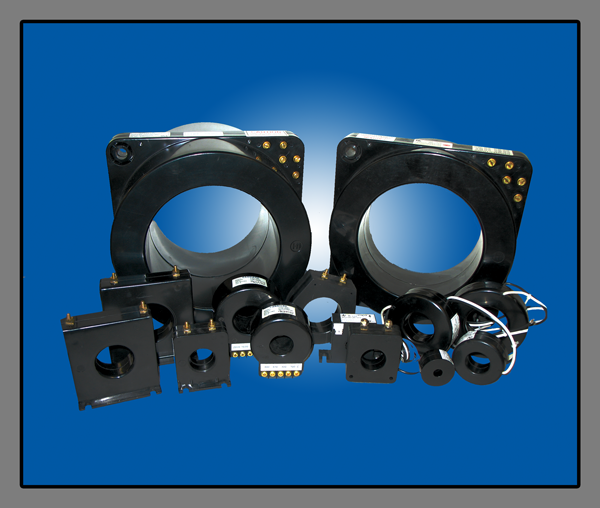

LOW VOLTAGE CTs - CURRENT TRANSFORMERS

These are 600V low voltage general purpose CTs for use in Switchgear, Panel boards, Control panels, Motor control centers, Engine generators, Transfer switches, UPS’, and other applications. IEEE/ANSI or IEC accuracy classes are available along with low cost models for high volume usage. A wide range of ratios from 50:5 to 5000:5 with 1 Amp or different secondary currents are available.

CTs can be single or multi ratios, with or without secondary resistor, and with or without mounting feet. Various construction options are available based on application - Plastic case, Resin cast, Tape insulated, or Resin dipped. Secondary connections are available with terminals, pins, leads, with or without connectors.LOW VOLTAGE VTs - POTENTIAL TRANSFORMERS

These are 600V low voltage VTs used for AC voltage measurement in Panel boards, Metering control panels, LV switchgear, Motor control centers, Engine generators, Transfer switches, UPS’, and other applications in a step-down environment, to monitor voltage. They are designed for connection line-to-line or line-to-neutral in the same manner as ordinary voltmeters. The secondary voltage bears a fixed relation with the primary voltage, so that any change in potential in the primary circuit will be accurately reflected in the meters, or other devices connected across the secondary terminals. Potential transformers can be used with voltmeters for voltage measurements, or they can be used in combination with current transformers for watt-meter or watt-hour meter measurements. They are used also to operate protective relays and devices, and for many other applications, and since they are used in a monitoring capacity, they generally require much greater accuracy in design.

Potential Transformers come in a wide range of ratios with secondary voltages 100/110/120V (different secondary voltages are possible). Single-phase or 3-phase designs are available in Plastic cased or Resin cast molded construction, with or without mounting brackets.

Standard designs are 60Hz but 50 and 400Hz designs are available. IEEE/ANSI or IEC accuracy classes are available along with low cost models for high volume usage. A wide range of ratios from 50:5 to 5000:5 with 1 Amp or different secondary currents are available.Metering Current Transformers

Metering CTs have accuracy rating at specified standard burdens called Accuracy Class. This defines the performance characteristics of a CT and the maximum burden allowable on the CT’s secondary. Metering CTs are designed to be extremely accurate from very low current to the maximum current rating of the CT. Revenue grade CTs are special type which are used by utility companies for billing purposes.

Accuracy Class defines the performance characteristics of a CT which includes the maximum burden allowable. CTs can be further separated into two groups; Metering Accuracy CTs or Relaying Accuracy CTs, and can have ratings for both groups.1. Rated Ratio Accuracy Rating - a number which is certified by the manufacturer to be accurate to within the rated ratio expressed as a percent.

2. Maximum Burden - This is the maximum burden or load that may be placed on the secondary without causing an error greater than the stated accuracy classification. For Metering Class CTs, burden is expressed as ohms/impedance.

We provide commercial grade, low cost current transformers with center window type (donut style) constructions. CTs are available in many different sizes with capabilities for measuring 50-400Hz and currents of 5A to 15000A. Typical burden ratings for IEC are 1.5 VA, 3 VA, 5 VA, 10 VA, 15 VA, 20 VA, 30 VA, 45 VA and 60 VA (special secondary currents are available). ANSI/IEEE burden ratings are B-0.1, B-0.2, B-0.5, B-1.0, B-2.0 and B-4.0.

A burden rating of B-0.2 means a CT can permit up to 0.2 ohms of impedance in the metering circuit, before its output current is no longer a fixed ratio with respect to the primary current.

Most models are available as U.L. recognized devices. They can be specified with or without mounting feet and the secondary can be leads, terminals, or per customer requirement.

- UPS systems

- Transfer switches

- Motor-generator sets

- Commercial sub-metering

- 3 CTs in one package for 3-phase metering

- Accurate measuring for metering/WATT/VAR

- Current sensing, recording, monitoring and control

- Control panels and drives

THREE PHASE CTs - CURRENT TRANSFORMERS

A 3-phase current transformer is made with three single-phase current transformers packaged together as one unit. They are usually encased in plastic or resin housing, and are typically used in motor control applications with 3-phase metering and overload protection applications. These CTs are compact and easier to install, compared to three single-phase CTs.

Various round and rectangle window options are available and are primarily used for 3-phase metering in MCC (motor control centers) for 3-phase relaying, metering, and overload protection.

A wide range of ratios are available from 50:5 to 4000:5 in Plastic cased or Resin molded. Various secondary options are available - terminals or lead wires.Relay Class Protection Current Transformers

Relay Accuracy CTs are not as accurate as Metering Accuracy CTs and are designed to perform with a practical degree of accuracy over a wide range of currents. These CTs are typically used for supplying current to protective relays. The wide range of currents allows the protective relay to operate at different fault levels.

A relaying accuracy class window type CT has a uniformly distributed low-reactance winding, such that the transformer ratio can be calculated. The secondary terminal voltage will provide 20 times the normal secondary current to a standard burden without exceeding 10% ratio error. In addition, the ratio error must be limited to 10% at any current from 1 to 20 times the rated current and at any burden.

Typical burden ratings for IEC are 1.5 VA, 3 VA, 5 VA, 10 VA, 15 VA, 20 VA, 30 VA, 45 VA and 60 VA (special secondary currents are available). ANSI/IEEE burden ratings are B-0.1, B-0.2, B-0.5, B-1.0, B-2.0 and B-4.0.

A burden rating of B-0.2 means a CT permits up to 0.2 ohms of impedance in the metering circuit, before its output current is no longer a fixed ratio with respect to the primary current.

- Protection relays/Relay panels

- Earth fault protection

- Bussing type, oil-immersed CT in power transformer

- Control panels and switch boards

- Air/Gas circuit breakers

- Motor control cubicles

- Power control centers

- Bus bar protection systems

- Differential protection systems

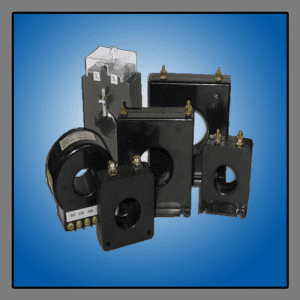

IEEE C57.13 and IEC Class CTs

These current transformers are designed to meet the requirement of ANSI IEEE C57.13 standard or IEC 60044 standard. CTs are typically used for metering and relaying applications such as switchgear, MCCs, switchboards, etc. Single ratio or multi ratio models are available with various secondary termination options (leads, terminals etc.). These CTs come with wide primary current range. Usually secondary current is 5 Amp or 1 Amp.

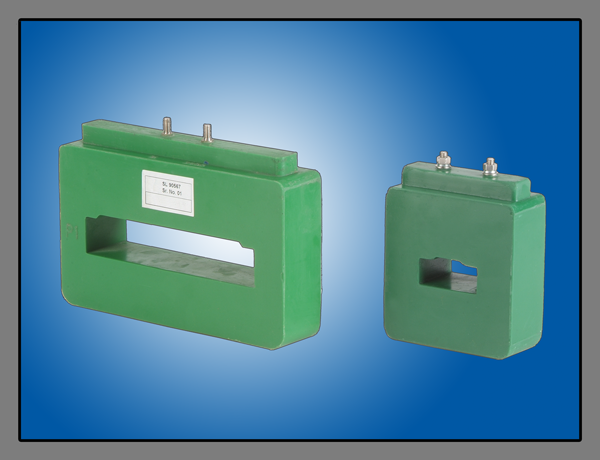

SPLIT-CORE CURRENT TRANSFORMERS

This type of current transformer is available to measure AC currents from 100 Amp to 3000 Amp, at 50 to 400Hz, with ratios from 50:5 Amp to 3000:5 Amp. Voltage output is possible with built-in resistor. These transformers are very popular in sub-metering applications, where existing systems are being upgraded and it is impractical to isolate the primary conductor. It is even possible to install this type of transformer while the conductor is energized; however, it is paramount that certain safety precautions be followed under such conditions. Rectangular in shape, standard split-core models are available with window dimensions up to 2.40" X 5.71". Larger, custom designed sizes are available by special order. Secondary burdens of 1.0 up to 50VA are common in split-core current transformers. Note that because of the split core construction, accuracy ratings are defined in part by the care in which the user installs the device.

LARGE FRAME CURRENT TRANSFORMERS

These are used for measuring 50-400Hz currents in bus bars and other large conductor systems. Typical configuration is 100A to 9000A primary current with secondary of 1 Amp or 5 Amp (special secondary currents are also available).

Inside areas are as large as 8.06” x 22.06" x 27.00" and 12.80” x 13.58". All models come in an outer plastic case and are available with IEC Ratios/Accuracies, non-standard thermal rating, different encapsulation, or different secondary termination. CTs are UL, cUL Recognized and CSA Certified.RECTANGLE CTs - CURRENT TRANSFORMERS

Hill Technical has an extensive range of rectangular current transformers, which are typically used for metering and relaying applications. Rectangle windows of the CTs can fit around primary bus bars or cables in applications where physical size and placement are very important. The secondary can be lead wires or terminals.

Rectangular CTs are used for measuring 50-400Hz currents from 100 Amp to 9000 Amp primary current with secondary of 1 Amp or 5 Amp (contact us for special secondary currents).

Inside areas are as small as 1.69" x 0.43" and as large as 8.06” x 22.06" x 27.00" and 12.80” x 13.58". All models come in an outer plastic case and are available with IEC Ratios/Accuracies, non-standard thermal rating, different encapsulation, or different secondary termination. CTs are UL, cUL Recognized and CSA Certified.AUXILIARY/SUMMATION CTs - CURRENT TRANSFORMERS

Summation CTs can have many different secondaries and are used to detect an unbalanced system condition typically due to fault. These have a wound primary with current ratings up to 50 Amps. The summation CTs converts 3-phase values into a single-phase value to operate a relay correctly. It accomplishes this by comparing the values derived from the current in the three phases of the primary circuit. It converts the 3-phase system into positive, negative, and zero sequence components. Current ratios range from 5:0.100 to 5+5+5+5+5:5.

The line of the summation current transformer is connected to the primary of an auxiliary CT. Each line energizes a different number of turns on the primary side of the auxiliary CTs. The resulting single-phase output appears across the secondary. Various accuracy classes for metering or relaying and several sizes and ratios are available.MEDIUM VOLTAGE INSTRUMENT TRANSFORMERS

Our medium voltage products provide current and voltage measurements for the protection and monitoring of medium voltage power systems. Instrument transformers are necessary to deliver values that can be used by metering or protection units, analogue devices, or supplied to digital processing units after analog/digital conversion of the input signal. They also provide galvanic separation.

These range from Indoor CTs rated up to 36kV both Bar type and Window type to Indoor PTs are rated up to 25.5kV. Single-phase, 3-phase, single-bushing, and 2-bushing PTs are available.

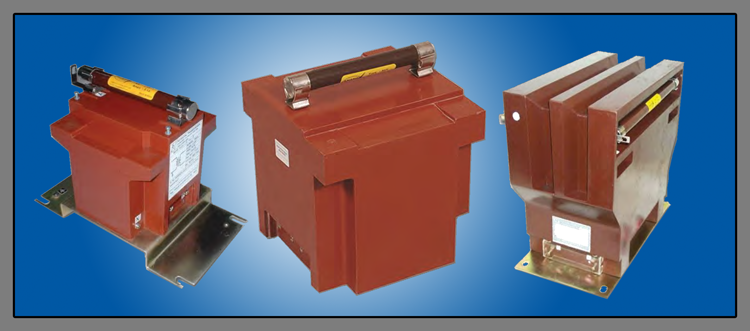

Medium voltage instrument transformers are made utilizing a fully automated resin encapsulation system consisting of automatic resin casting machine, vacuum casting & heating chambers, vacuum mixing tanks, curing ovens, and molds using special casting fixtures.MEDIUM VOLTAGE SWITCHGEAR CTs - CURRENT TRANSFORMERS

We offer a wide range of current transformers designed specifically for low and medium voltage switchgear used in ANSI and IEC markets. 50Hz current transformers are intended to meet IEC standards. Switchgear CTs are designed to slip over primary bushing circuit breakers in MV switchgears, and are designed to mount inside switchgear panels through the corner mounting holes. They are available in ANSI or IEC accuracy classes for relaying and metering applications.

By producing our cores with a high-quality silicon grain-oriented steel, and then using a propriety annealing process to remove magnetic stresses introduced in the core winding process, we can adhere to the most stringent accuracy standards with minimal excitation losses.In addition, the CT windings are evenly distributed around the insulated core to ensure lowest possible leakage on each tap. After manufacture, each CT is tested for all the routine test parameters as per IEEE/ANSI C57.13, including Accuracy, Polarity, Di-electric and Turns-ratio. Each CT has a unique serial number, so excitation curves can be published for each design having a relay rating, and are traced back to the factory test report.

CTs are: UL Recognized, CSA Certified to IEEE ANSI C57.13 standard and cUL Recognized to IEC 61869-1, IEC 61869-2, IEC 60044, and have the CE Mark.MEDIUM VOLTAGE CTs - CURRENT TRANSFORMERS

Medium voltage current transformers from 5kV to 35.5kV Class system voltages are available in Bar Type, Window Type, and Wound Primary Type, with primary current rating up to 1000 Amps. CTs are encapsulated with epoxy or polyurethane resin cast construction, and are able to withstand heavy fault conditions, but are not made for exposure to sunlight. The core and coil assemblies are vacuum molded to ensure a homogenous, bubble-free construction. The medium voltage CT construction provides high di-electric and BIL 4.5 to 125 full wave crest kV.

The MV CTs can be supplied with round or rectangle window in the center. This provides easy installation for customers as they can use their primary cable or bus bar through the CT ID. Usually these CTs come with equal-potential shield around the ID surface. This equal-potential screen is attached with a pig tail (lead with connector) which comes out of the ID surface. This arrangement allows uniform distribution of charge (non-concentrated) around the surface, which further ensures that the CTs withstand high current and high voltage environment in long term use.

We also provide wound primary medium voltage CTs where primary and secondary terminals are usually taken out from the top surface of the CTs. Customers can make the primary connections using these terminals. The bus bar type MV CT construction usually have resin cast CTs with bus bar built into the construction. Various primary bar arrangements can be supplied to suit most applications. Medium voltage CTs come with or without mounting brackets.

MV CTs are designed to meet IEEE C57.13 or IEC 60044 standards. Partial discharge test is carried out as per Canadian CAN3-C13-M83 or as per IEC 60044. Standard burdens are used to measure accuracies (ratio and phase angle error) on calibrated accuracy test bridges. Hi-pot tests are carried out as per the required standards.

- Metering and relaying

- Energy meter panels

- Medium voltage switch gears and control panels

- Medium voltage circuit breakers

- Motor control panels

MEDIUM VOLTAGE POTENTIAL TRANSFORMERS

Medium voltage potential transformers for up to 25kV class system voltages are available. PTs are encapsulated with epoxy or polyurethane resin cast construction.

The core and coil assemblies are vacuum molded to ensure homogenous, bubble-free construction. PT construction provides high di-electric and BIL strength.MEDIUM VOLTAGE VTs - POTENTIAL TRANSFORMERS - SINGLE-PHASE

Medium voltage indoor PTs are constructed in various configurations – double pole or single pole designs. PTs can be supplied with two fuses, one fuse or no fuse, or internal fuse hub. MV PTs with fuse clips can be provided if required by the customer. Switchgear style design is also available. Usually these PTs are supplied with the metal mounting bracket.

Primary Voltage Ranges: 2400 to 4800, 2400 to 14400, 4160 to 13800, 7200 to 24000, 12000 to 24000, 18000 to 24000, 10200 to 24000, 24000 to 34500, 15240 to 34500. Voltage Class: 5.6kV, 15.5kV, 25.5kV, 36.5kV.3-phase assembly using single-phase VTs with fuse hub design for a directly earthed primary connection.

MV PTs are designed to meet IEEE C57.13 or IEC 60044 standards. A partial discharge test is carried out as per Canadian CAN3-C13-M83 or as per IEC 60044.

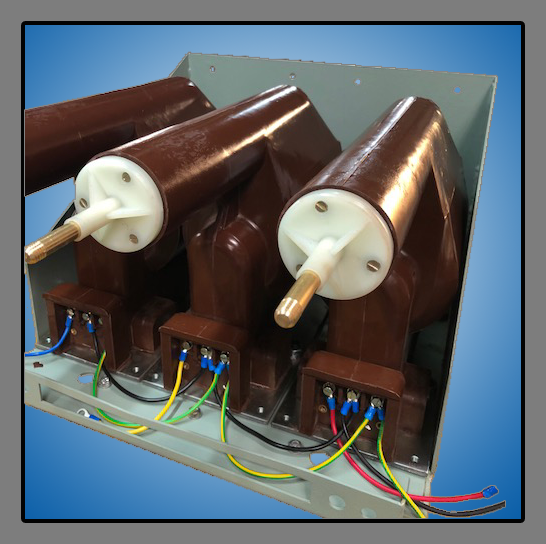

Standard burdens are used to measure accuracies (ratio and phase angle error) on calibrated accuracy test bridges. Hi-pot tests are carried out as per the required standards.MEDIUM VOLTAGE VTs - POTENTIAL TRANSFORMERS - 3-PHASE

We also offer indoor medium voltage PTs with 3-phase construction. 3-phase MV PTs designed in a single package are typically used for the application where physical size and location are very important. These PTs can be supplied with or without fuses. Terminal locations are clearly marked for proper connections.

Standard Wye-Wye primary connection (L-L) voltages are: 2400, 3300, 6600, 7200, 8400, 11000, 12000, and 13200. Secondary (L-L) voltages of 230, 120 and 110 are possible.

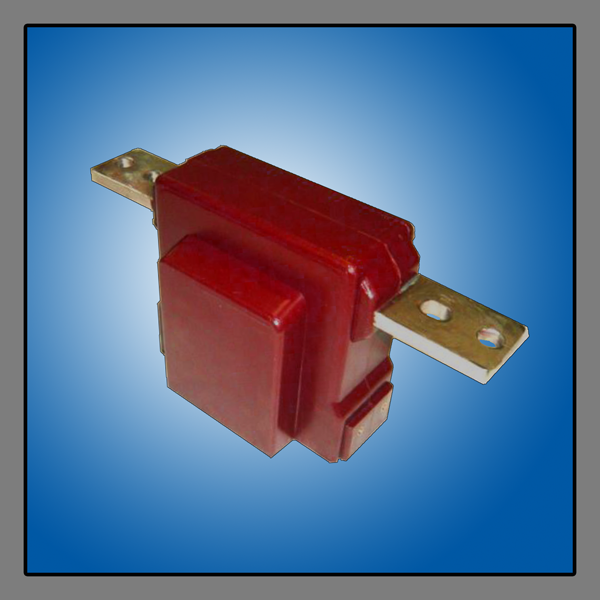

MV PTs are designed to meet IEEE C57.13 or IEC 60044 standards. Partial discharge test is carried out as per Canadian CAN3-C13-M83 or as per IEC 60044. Standard burdens are used to measure accuracies (ratio and phase angle error) on calibrated accuracy test bridges. Hi-pot tests are carried out as per the required standards.MEDIUM VOLTAGE CPTs -CONTROL POWER TRANSFORMERS

Medium Voltage Control Power Transformers (CPTs) are single-phase dry-type transformers used to supply control power in medium voltage switchgear and transformers. It has open construction with an epoxy resin encapsulated coil.

Power ratings of 5, 10 and 15kVA with nominal primary voltages range from 2.4kV to 15kV and secondary voltages typically are configured for 120/240V (series parallel) operation. It is supplied with three +/-2.5% taps above and below nominal voltage on the primary winding.

For low power losses, the magnetic core is wound with grain-oriented electrical steel, and the high-voltage coil is vacuum encapsulated in epoxy resin. In addition to protecting the coil from moisture and foreign particulate matter, the resin epoxy provides a higher ability to withstand mechanical forces during short-circuits, than standard varnished Vacuum Pressure Impregnation (VPI) or “dip in varnish and then bake” process.

The secondary terminals are 1/2"-13 UNC brass bolts. Primary connections are 1/4"-20 UNC brass female terminals. The stainless-steel base of the CPT has 14mm holes for mounting in your equipment.

Typical applications include MV Switchgear, MV Motor Control, MV Generator, and Transformer Neutral Grounding.

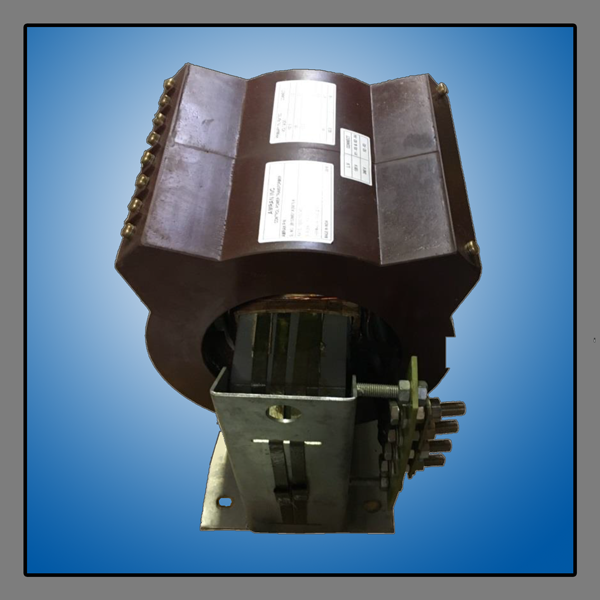

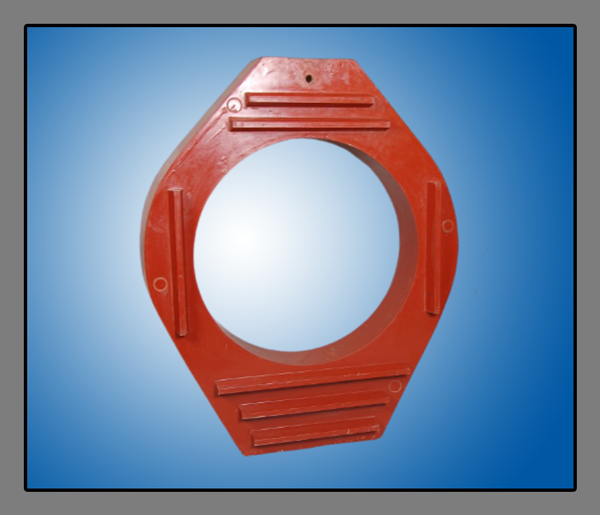

BUSHING CTs - CURRENT TRANSFORMERS

We provide BCTs (Bushing Current Transformers) for dry (Gas insulated) or oil-immersed applications. BCTs are manufactured for many different applications, such as medium and high voltage circuit breakers, large power transformers up to tens of MVA, and large power generators.

BCT cores are made using large rolls of silicon grain oriented electrical steel. The material is wound using a high speed, programmable winding machine with the mandrel set for the specific core ID needed. The steel winding process introduces mechanical stresses in the core which impacts the magnetic characteristic of the core, manifesting itself in unwanted electrical characteristics, which in turn affect the CT accuracy. In order to remove these stresses, the wound core is annealed in a state of the art, highly controlled furnace where temperature and time cycles are monitored and recorded digitally using various controllers.

The core winding material and annealing processes permit us to have the smallest excitation losses in order to meet the most stringent standards. Cores are insulated using polyester film, and an epoxy varnish is applied on the core to prevent moisture ingress. The secondary winding is fully distributed around the core to guarantee the lowest possible leakage on each tap. Various outer encapsulation methods are used, depending on application – paper (crepe paper, craft paper) insulation, varnished or un-varnished cotton tape insulation, etc. Polyester film tape construction is also used for some applications.

Bushing CTs can be manufactured to meet high relaying and metering accuracies, including the highest accuracies possible by using extremely low loss nanocrystalline cores. They can be made using single core or multi core designs and with single or multi ratios.

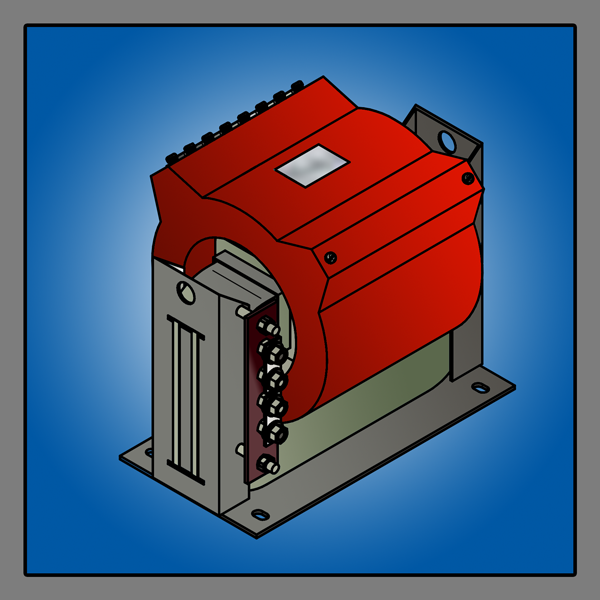

GENERATOR STYLE CTs - CURRENT TRANSFORMERS

Generator style CTs are designed specifically for high current applications inside large generators. They are mounted and stacked over the output bushings, and bus duct in large generators for metering or relaying applications. They can have current rating of 5000 to 30000 Amps. These CTs typically have tape insulated outer construction. Special mounting boards are used for floor mountable or wall mountable applications. Hill Tech also provides generator style CTs with cast resin type construction for generator applications.

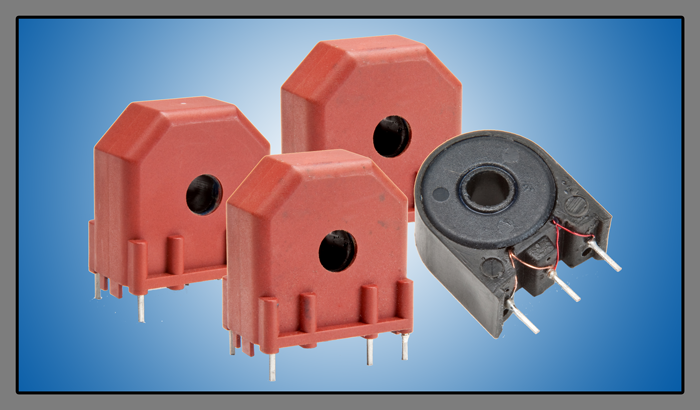

These CTs are constructed with epoxy or polyurethane resin construction, usually mounted around the generator bus bars with round or rectangle shape. Mounting arrangements can be provided as per customer requirement. These generator style CTs usually have a terminal box on top to meet customer requirements. Both tape wound and cast resin CTs can be provided with shielded winding, to reduce the effects of magnetic flux interference from adjacent conductors.MINIATURE and PC MOUNT 50 TO 400Hz CTs - CURRENT TRANSFORMERS

These are 50-400 Hz CTs constructed using one of the following methods: Plastic casing, Resin casted, Resin dipped, or Tape insulated. Typical turns ratio ranges from: 500:1 to 4000:1 with Accuracy: Class 0.1 to Class 1.0 or 0.1% to 0.5% mV output possible. Primary to secondary insulation is 4kV AC.

Various mount options are available: Thru-hole PCB mounting, Secondary leads and PCB mounting, Primary winding with lugs or terminals, or 3 in 1 design.- Energy meters for accurate current measurement

- Current control

- Current signature of motors

- Load sensing

- Ground fault sensing

- Monitoring of process parameters

- AC level to logic conversion

PC MOUNT 20 TO 400kHz CURRENT TRANSFORMERS

Our current sensors are used for measuring high frequency primary currents up to 30 Amps. This provides a small footprint for the design engineer looking to detect high frequency current, while isolating the signal from potentially high currents in the circuit. They provide a low-cost solution for any control system and most AC current monitoring/measuring applications. The current sensors can serve as the feedback elements from SMPS outputs and the pulse control module.

These are fully encapsulated for optimal PC board mounting, with primary current rating to 30 Amps and primary to secondary isolated to 2500 VAC. CTs meet VDE norms and have performance optimized over the specified current and frequency range.- Isolated current feed-back signal in switch mode power supplies

- Motor current load/overload

- Isolated bi-directional current sensor with full wave bridge

- Lighting

- High resolution sonar current

- Ultra-sound current

- Switch controls

ROGOWSKI COILS & SENSORS

Rogowski sensor is an air-core – usually toroidal or rectangle coil placed around the conductor. Rogowski sensors do not use magnetically permeable cores. Since there is no magnetic core to saturate, one of the most important properties of these coils is that they produce extremely linear output. Rogowski sensors are very popular for the application requiring excellent linearity for very high current range.

We also manufacture a combination of Rogowski CTs and CTs with magnetic core. Both of these are combined into one construction. These combination CTs are typically used for protection applications where magnetic core CTs can operate for low current range, and then once it saturates, Rogowski CTs pick up signals and provide appropriate output.It is not easy to wind Rogowski sensors. We have developed equipment and expertise to wind these products uniformly, so that the coil does not pick up any magnetic signals from adjacent circuitry. Special machines are used for accurate winding and state of the art in-house test facilities, to test Rogowski sensors for required parameters.

OIL INSULATED CTs & VTs

Oil insulated CTs & PTs are designed for outdoor use. They can be manufactured for up to 36kV system voltage. Besides standalone CTs and PTs, we can manufacture a combination unit comprising of both. For example, a metering unit consisting of 3 CTs and 3 VTs (3-phase 4 wire application) with accuracy class up to 0.2 (IEC) and 0.15 class (IEEE/ANSI). For 3-phase 3 wire application, Hill Tech also offers the combination unit of 2 CTs and 1 3-phase VT. These units are strongly built internally to withstand electrical and mechanical stresses. Units are provided with nitrogen cushioning protection and are duly pressure tested.

Hermetically sealed units can be provided as well as CTs with Live Tank/Dead Tank design for system voltage of 25kV and above, depending on customer requirements. Pole or pad mounted tanks are usually processed with either hot dip galvanizing or outdoor paint on it. Primary terminals can be provided with either stud type arrangement or with attachment of connectors, suitable for A.C.S.R. (Aluminum Conductor Steel Reinforced) conductors. Oil level indicators, pressure release devices, oil fillings, and draining plugs are standard features. Most of these units are custom designed to meet exact application and requirement. These CT and PT units are suitable for all metering, relaying and differential protection applications. They are 100% tested to meet the required IEC or IEEE/ANSI or relevant test standards.